Slip-on-Flange-Dimensions-Class-150-to-Class-1500

Renine Metalloys LLP offers a comprehensive range of slip-on flanges designed to meet various pressure ratings from Class 150 to Class 1500.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

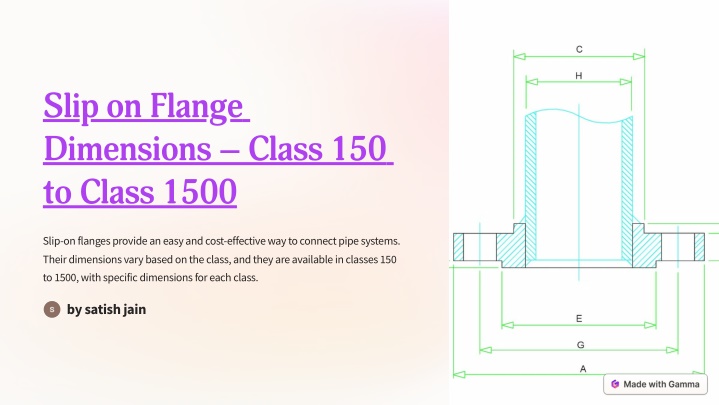

Slip on Flange Dimensions Class 150 to Class 1500 Slip-on flanges provide an easy and cost-effective way to connect pipe systems. Their dimensions vary based on the class, and they are available in classes 150 to 1500, with specific dimensions for each class. by satish jain

Class 150 Slip on Flange Dimensions Size Outside Diameter Thickness 1/2" 3.50" 0.44" 3/4" 3.88" 0.50" 1" 4.25" 0.56"

Class 300 Slip on Flange Dimensions Size Outside Diameter Thickness 1/2" 3.88" 0.56" 3/4" 4.25" 0.62" 1" 4.63" 0.69"

Class 600 Slip on Flange Dimensions Size Outside Diameter Thickness 1/2" 3.88" 0.62" 3/4" 4.25" 0.69" 1" 4.63" 0.81"

Class 900 Slip on Flange Dimensions Size Outside Diameter Thickness 1/2" 5.00" 0.75" 3/4" 5.50" 0.88" 1" 6.00" 1.00"

Class 1500 Slip on Flange Dimensions Size Outside Diameter Thickness 1/2" 6.25" 1.12" 3/4" 7.00" 1.25" 1" 7.50" 1.38"

Flange Size 1 2 Range of Sizes Precision Design Flanges are available in various sizes to accommodate different pipe diameters and system requirements. The dimensions are precisely engineered to ensure seamless integration with pipes of specific sizes.

Flange Thickness Impact on Strength Machining Considerations Material Compatibility Thicker flange sizes provide greater strength and durability for high-pressure applications. Thicker flanges may be necessary for certain corrosive or high- temperature environments. Thicker flanges may require special machining equipment, impacting manufacturing costs. Thin flanges are suitable for lower pressure systems where space is a consideration.