Ship Repair and Alteration Committee Updates and Key Changes - SSRAC 2019

The SSRAC 2019 meeting discussed standard specifications for ship repair and alteration, subcommittee details, hull preservation processes, NSI NAVSEA standard items, and key changes in quality management, deck covering, cleaning, and painting requirements. Notable modifications include reduced checkpoint notification time, elimination of chloride, and standardized testing criteria.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

SSRAC 2019 Robert Cloutier September 10 12, 2019 NSRP Joint SP&C and EH&S Panel Meeting Quonset Point, RI 1

SSRAC 2019 (FY21) SSRAC 2019 (FY21) Standard Specification For Ship Repair and Alteration Standard Specification For Ship Repair and Alteration Committee Committee 24 24 - - 28 28 June June2019 2019 VASCIC Newport News Shipbuilding Virginia Advanced Shipbuilding and Carrier Integration Center 2

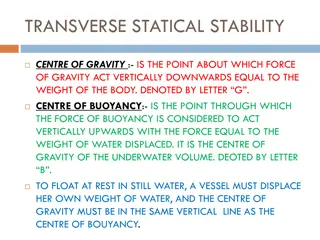

SSRAC - Subcommittees Unless designated Environmental / Safety / Health Hull / Preservation Machinery / QA Piping / Boiler Electrical / Electronics General (non-trade specific) 4-E / Phraseology 3

SSRAC Hull / Preservation Unless designated as a Government Representative, Contractors are non-voting participants of the Subcommittee also known as Participant Witnesses . Our Industry Partners serve as information providers to the Subcommittees, and they do not participate in the deliberations by the Government members of the Subcommittees to reach consensus on what to recommend to the Steering Committee, nor do they vote on any matter before the Subcommittee. NSRP SP&C Panel Representatives Robert Cloutier Steve Cogswell 4

NSI NAVSEA Standard Items 009-04 Quality Management System 009-26 Deck Covering Requirements 009-32 Cleaning and Painting Requirements 009-124 TSN Thermal Sprayed Non-skid Proposals for change Adopted Adopted as modified Not adopted Other 5

Hull / Preservation Subcommittee Reviewed a total of 83 total change proposals 16 Adopted 32 Adopted as Modified 32 Not Adopted 3 Other 6

Key Changes 009-04 Check-point notification reduced from 4 to 2 hours 009-32 Eliminate Chloride and require Conductivity Measurements Mil-PRF-23236, Type VII, Class X/18: Single Coat UHS epoxy, limited to 3% touch-up with alternate coatings Non-skid: segregated rolled vs spray applied Standardized the number of reading for testing; per 5,000 sq ft Anchor tooth profile for non-skid was 10 vs 13 Conductivity reading was 9 vs 13 Dust test was 10vs 13 009-124 Complete review for Thermal Sprayed Non-skid FY20 7

Discussed, but not adopted 009-32 Non-skid applications Requirement to apply Type V spray-able non-skid commercial equipment meeting A-A-28852 Requirements to mix non-skid with a mixer qualified to A-A-59984 Abrasive blasting on aluminum (non-ferrous metals) Waiting for final approval of SSPC-17 Thorough Abrasive Blasting 8

Opening Remarks Dale Hirschman: Technical Director, CNRMC Code 200 287 US Navy ships to maintain Limited Dry-docks available San Diego has the least available dry-dock locations Streamline dry-docking; Reduce schedule and time DDG 51 class: Optimum ~110 days 9

Navy/Industry NSI Review On-going Projects: 50% Checkpoint Reduction Pilot Initiative An aggressive stretch approach with an objective of executing pilot availabilities with significantly reduced Checkpoints content 2 East Coat 2 West Coast USS ARLEIGH BURKE (DDG 51) Norfolk, VA USS BULKELEY (DDG 84) Norfolk, VA USS SHOUP (DDG 86) Everett, WA USS ESSEX (LHD 2) San Diego, CA 10

Underwater Hull Paint Pilot Background: Industry proposed that the underwater (U/W) hulls of Navy ships could be painted in one quarter of the time if accomplished the way MSC U/W hull preservation is accomplished CNRMC observed an MSC ship undergoing U/W hull preservation and acquired the MSC specification. Required checkpoints were almost identical. The only technical difference was a slightly higher threshold for chlorides (conductivity). Obtained TWH concurrence to pilot the MSC model Way forward: Developing an NSI that describes the application process for U/W hull preservation (95% complete). Developing contract that will be used in the solicitation package for: Obtaining a Third Party Paint OEM to act as government representative. Purchase paint as GFM. Provide a two year warranty for the paint. 11

Drydock Propulsion Work Master Specification Catalog (MSC) Checkpoint Reduction Initiative A systematic and sustainable approach for reviewing Work Templates in order to reduce the number of Checkpoints (by system/equipment). Initial systems for review include: SWILN 245 SWILN 243 SWILN 244 Controllable Pitch Propellers (CPP) Propulsion Shafting Propulsion Shaft Bearings 312 (G) Checkpoints in FY19 227 (G) Checkpoints in FY19 146 (G) Checkpoints in FY19 12

Clarification of 009-90 Change to 009-90 Technical Representative; provide The NSI 009-90 Technical Representative will only be contracted by the prime contractor and the same company cannot provide both the Technical Representative and perform the actual production work. CNRMC Letter: Clarification for Use of NAVSEA Standard Item 009-90, During Surface Ship Maintenance Availabilities Clarifies OEM role augmenting the Government oversite vice production support. 4E Guidance: Generally technical support should be provided by the supervisor. The Technical Representative should only be requested when: Technical documentation is not available to the supervisor. The supervisor does not have sufficient personnel to support oversight of maintenance being performed. Special tools or equipment are required. The supervisor does not have personnel with the knowledge or expertise to support the maintenance being performed. Planners must identify what services the technical representative is to provide. NSI 009-90 will be invoked as a pre-priced option when the need for a Technical Representative for a Work Item in an availability is unknown. When invoked in a work specification, the Technical Representative providing the technical support may witness/conduct (G) checkpoints as authorized by the supervisor. 13