Surface Modification of Implants Using Calcium Silicate Coating

Surface modification of implants using calcium silicate (CS) coatings prepared by electrophoretic deposition (EPD) is a promising technique to enhance biocompatibility and bioactivity. This project focuses on studying the influence of charging salt on the coating formation, preparing thin layers of Eu-doped CS, and evaluating mechanical properties and bioactivity. Another project involves the preparation of a Si3N4/SiC/CaF composite for high-temperature tribological applications, emphasizing densification, microstructure development, and mechanical/tribological properties measurement. Lastly, a material study of museum ceramics involves characterizing ceramic sherds to determine firing temperature and aid in artifact classification. Both projects offer valuable insights into biomaterials and ceramic materials.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

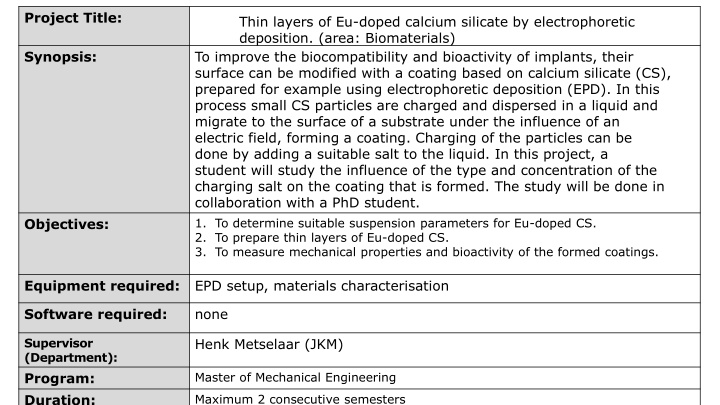

Project Title: Thin layers of Eu-doped calcium silicate by electrophoretic deposition. (area: Biomaterials) Synopsis: To improve the biocompatibility and bioactivity of implants, their surface can be modified with a coating based on calcium silicate (CS), prepared for example using electrophoretic deposition (EPD). In this process small CS particles are charged and dispersed in a liquid and migrate to the surface of a substrate under the influence of an electric field, forming a coating. Charging of the particles can be done by adding a suitable salt to the liquid. In this project, a student will study the influence of the type and concentration of the charging salt on the coating that is formed. The study will be done in collaboration with a PhD student. 1. To determine suitable suspension parameters for Eu-doped CS. 2. To prepare thin layers of Eu-doped CS. 3. To measure mechanical properties and bioactivity of the formed coatings. Objectives: Equipment required: EPD setup, materials characterisation Software required: none Henk Metselaar (JKM) Supervisor (Department): Program: Duration: Master of Mechanical Engineering Maximum 2 consecutive semesters

Project Title: Sintering and microstructure development of silicon nitride/silicon carbide/calcium fluoride ceramic composites for high temperature tribological applications. (area: ceramic materials) Ceramics are hard materials that keep their strength at high temperatures. This makes them suitable for applications where materials are subjected to high temperature and high stress, such as sliding contacts. At such high temperatures liquid lubricants can not be used. Instead, a composite is made such that the additive is squeezed out during contact and forms a lubricating film. In this project, a student will study the preparation of a composite of silicon nitride matrix with silicon carbide fibers to add strength and toughness with addition of calcium fluoride as an internal lubricant. Special attention should be paid to densification and development of microstructure during sintering and the resulting mechanical and tribological properties of the resulting composite. This project will be done in collaboration with a PhD student. Synopsis: Objectives: 1. To determine suitable sintering additive and parameters for a Si3N4/SiC/CaF composite. 2. To prepare dense specimen of ceramic composite. 3. To characterise mechanical and tribological properties of the ceramic composite. Ball mill, tube furnace, (high temperature) tribometer. Equipment required: Software required: none Henk Metselaar (JKM) Supervisor (Department): Program: Duration: Master of Mechanical Engineering Maximum 2 consecutive semesters

Project Title: Material study of museum ceramics. (area: materials) Synopsis: Archaeological ceramics can teach us a lot about the lives of our ancestors. For example, the way in which they are formed and fired is telling of the technology level at the time of production. During firing, clay minerals dehydroxylate and become amorphous (this is called vitrification), minerals undergo phase changes and shrinkage of the object occurs. From observation of structure, microstructure and phase composition it is therefore possible to make inferences about the firing procedure/temperature. In this project, a student will characterise ceramic sherds (pieces) from the Museum of Asian Art (UM) using XRD, FESEM, TGA/DTA, TMA, FTIR etc in order to find out the firing temperature and to help classification of the sherds. This title is linked with an ongoing funded project. 1. To obtain representative samples with minimal damage to the artefacts. 2. To characterise the material with a range of techniques. 3. To link the materials characterisation to age, sintering temperature and classification of the artefacts. XRD, FESEM, TGA/SDTA, TMA, FTIR Objectives: Equipment required: Software required: Possibly: statistical software Henk Metselaar (JKM) Supervisor (Department): Program: Duration: Master of Mechanical Engineering Maximum 2 consecutive semesters

Project Title: Processing and sintering study of clay/volcanic ash mixtures. (area: materials) Synopsis: Labu Sayong is a famous type of pottery made in Perak, but it is not made from clay as you might expect. It is made from a mixture of clay and volcanic ash. This volcanic ash (VA) originates from Toba (Sumatera), which erupted 75000 years ago, sending large amount of molten material into the atmosphere. This formed bubbles that froze, broke and rained down as glass shards with a high silica content. Over time, this ash mixed with clay deposits. While clay/VA mixtures have also been used in the US, those contained much larger glass shards than the local ash. In this project, a student will use the local material with various amounts of VA and do a detailed study on the forming, densification and sintering behaviour of the mixtures. This title is linked with an ongoing funded project and in collaboration with a Labu Sayong manufacture. 1. To prepare mixtures of clay/VA will well defined particle size and composition. 2. To characterise the sintering behaviour of the clay/VA mixtures. 3. To characterise mechanical properties and visual aspect of the sintered material. Furnace, TGA/SDTA, TMA, FESEM, polarising optical microscope. Objectives: Equipment required: Software required: none Henk Metselaar (JKM) Supervisor (Department): Program: Duration: Master of Mechanical Engineering Maximum 2 consecutive semesters

Project Title: Classification of high voltage cable joint defects using support vector machine and noise reduction on partial discharge signals In this work, classification of high voltage cable joint defect types using support vector machine and noise reduction techniques on partial discharge signals will be performed. Four cross-linked polyethylene (XLPE) cable joints with artificially created defects will be prepared based on the defects commonly encountered on site. Different noise reduction techniques will be applied to denoise the PD signals. The denoised signals will be used as a feature for classification of defects in cable joints using support vector machine. The classification results will be compared between the proposed method and the existing works to evaluate the performance of the applied techniques. 1. To perform measurement of partial discharge (PD) on artificially-prepared cable joint defects 2. To apply support vector machine and various noise reduction methods on PD signals for classification of XLPE cable joint defects 3. To compare the classification results between the proposed method and the existing works Partial discharge measurement setup, high voltage generation kit, cable joint Synopsis: Objectives: Equipment required: Software required: Supervisor (Department): Program: Duration: MATLAB, partial discharge analysis software Assoc. Prof. Ir. Dr. Hazlee Azil Illias (Electrical) Master of Power System Engineering / Master of Engineering (Power System) Maximum 2 consecutive semesters