Muon Phase2 Upgrade: INFN Collaboration for Detector Enhancement

The Muon Phase 2 upgrade project aims to improve the performance of muon detectors for the HL-LHC conditions. Collaborating with INFN, the project focuses on maintaining excellent triggering and measurement capabilities under harsher conditions. Key aspects include existing detector consolidation, new forward muon detectors, and DT electronics upgrades. The project involves R&D, replacement of electronics, and implementation of new triggering functionalities. INFN plays a significant role in the system maintenance, R&D commitments, and cost contributions for the upgrade.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

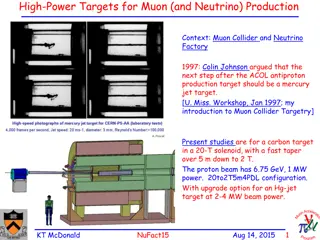

Muon Phase2 Upgrade Muoni: Piani e interessi INFN per l Upgrade di Fase2 Anna Colaleo - INFN-Bari Input dai responsabili nazionali: Davide P, Cristina R, Sandro V. Contributi da Gabriella P, Luigi G, Marco DV, Silvia M, Pigi, Stefano B., Robert C. Details about R&D and TDR preparation in Luigi s presentation CMS ITALIA Spoleto 15 Dicembre 2016. 1

CMS muon upgrade scope Goal: maintain excellent triggering, ID, and measurement of muons under harsher HL-LHC conditions (instantaneous and integrated L) up to | |<3 1. Existing detectors: consolidation of detector operation; DT, CSC and RPC electronics upgrade; 2. New forward muon detectors: GEM in GE1/1 (approved), GE2/1, and ME0; improved RPC in RE3/1 and RE4/1 DT Consolidation of the detector operation at HL-LHC detector longevity from GIF++ R&D DT and CSC electronics replacement to handle longevity issues and L1 trigger (750 kHz) rate and latency (12.5 s). Upgrade trigger/DAQ RPC system to handle longevity issues and be complaint to Phase2 CSC iRPC New forward detectors to handle most difficult region, with high background trigger and readout rates, and limited bending up to | |<3 ME0 GE2/1 GE1/1 2

The DT Electronics upgrade Needs: Fix legacy longevity issues Meet L1 trigger rate & latency, readout bandwidth requirements Enhance reliability Design plans: Same analog front end On-detector Minicrate replacement Time digitization using rad-hard, Flash- based FPGAs, and CERN GBT links Only one type of board vs. fourteen A single data path to USC Only optical patch panel and power supplies on towers L1 trigger functionalities move to USC Recycle much of the infrastructure Installation in LS3, EDR Q1/2020: major expenditures will start in 2020 3

DT Upgrade design and INFN interest Main items related to the replacement of MC on the chambers: - new Minicrate mechanics/integration (Bologna) - TDC implementation in FPGAs and OBEDT board (Padova) - optical links/clock distribution (Torino, Padova) Development of the trigger algorithms in the appropriate hardware platform (Bologna, Padova) For back-end electronics many decisions depends on common cDAQ/Trigger. 4

Costs, INFN interest and contribution Estimated CORE cost in MCHF (2014) DT Electronics Minicrate Electronics Trigger Electronics Opto-links INFN TP 3,3 2,1 0,7 1,326 0,872 0,276 Total 6,1 2,474 INFN interest in system maintenance, R&D. Possible commitments: Mechanics&integration - Bologna/Padova On-detector electronics - OBEDT and slow control -Padova, Torino Off-detector electronics - Bologna, Padova Optical links/clock distribution Torino, Padova INFN represents 50% in the DT community 5

RPC longevity and operation: 1) Issue for RPC (CSC) on emission of F compound in greenhouse gases C2H2F4, SF6 (CF4) CERN committed (by previous DoR) to reduce its annual GWP contribution to 20% of 2011 value by the end of LS3. (CERN-EDMS 1476311). Expected gas cost increase. a) b) Identify new (no or low GWP) gas mixtures (LNF , Gent, CERN-DT). If not: provided the detectors are relatively leak-tight, the % of total gas flow being refreshed can be either recuperated or abated Now can only be fulfilled by disconnecting up to 50 RPC s. Plan to repair as many RPC s as possible in EYETS + LS2. Aim to reduce to 55% of existing leak rate (1100l/hr) But the evolution up to 2040 is worrisome Help from CERN in implementing the plan is needed. Synergy with Atlas 6

RPC Longevity and operation: 2) Present link system is rad-soft, short on spares, prone to failure, unsupported post-LS2, not extendable to new forward iRPC. The new system should use RPC ~1 ns timing for L1 triggering on HSCPs, background suppression Control Board Control & diagnostic LVDS cables Link Board Link Board Link Board Synchronization Unit & LMUX Optic Links 90 m @ 1.6 GHz 492 fibers (before splitting) RPC legacy Link System was under L1 Trigger project. It has been agreed to bring into Muon project 1376 Link Boards in 108 Boxes, Steered by 216 Control Boards But the cost for the Upgrade not included in TP scope. FEB Requirements for the new system have been defined, similar solution to DT MiniCrate2 attractive (TDC followed by fast OptoLinks to USC) and under investigation. FEB FEB FEB FEB FEB Synergy inside INFN group between RPC and DT groups Resistive Plate Chambers Up to 6 layers of detectors. 480 chambers in barrel, 648 in endcaps 7 7

RPCs for RE3/1 and RE4/1 Consist of new 72 chambers (RE3/1 and RE4/1) and related electronics and services to extend the coverage in | | to 1.8 < | | < 2.4 using an improved design of RPCs (iRPCs), capable of handling the particle rates foreseen at HL-LHC. Reduced electrode resistivity: about 1010 cm (bakelite or glass option) Reduced electrode and gas gap thickness (<1.5 mm vs present 2 mm) New generation low-noise FE electronics for high efficiency/less aging (Petiroc2 Lyon design or Atlas design) Option: Glass Multigap chambers for high timing accuracy Baseline Double-gap configuration HPL (bakelite) electrodes, glass Plan to install between LS2 and LS3, EDR Q1 2019: expenditures will start in 2019 Multi-gap glass 8

Costs, INFN interest and contribution RPC Estimated CORE cost in MCHF (2014) Stations RE31 and RE41 Chamber assembly Electronics Power system Services Installation INFN 1,2 0,3 0,4 0,2 0,2 0,1 0.05 0,16 * Very preliminary. Based on cost of legacy system Total New endcap chambers 2,3 0.31 RPC Full Link system 1.3* 0,1 Total 3,6 0,41 I NFN interest to maintain the current system and support baseline solution with the known bakelite technology. Involvement and possible commitment in Phase2: Performance studies of new eco-friendly mixture LNF Contribution to the design of new link system - LNF, Napoli (tbc) Quality control of the bakelite production (spares chambers, new production) Napoli Power system for RE3/1-RE4/1 Napoli Quality control of the production chamber at CERN - Bari, LNF Development of the Front-end electronics (in synergy with Atlas) Bari 9

The GE2/1 detector The station GE2/1 consists of 72 triple-GEM chambers covering 20 GE2/1, with more than 3 times the area of GE1/1. To fit in 88 mm gap space, it will be the largest GEM detector ever built. Engineering design effort: Dimension of chamber is limited by base material size (PCB and foils): GE2/1 chamber segmented in 4 horizontal modules Increase of cost with respect to original design # foils, GEBs, fibers, power lines Keep the same on-detector boards: major costs already included in GE1/1 RE2/2 Costs scaled from GE1/1 costs Plan to install between LS2 and LS3, EDR Q4 2018: expenditures will start in 2019 10

-RWELL option CMS is currently investigating the application of the -RWELL technology for GE2/1 station : Motivation Drift/cathode PCB Simplified construction compared with a Triple-GEM (no foil stretching needed) less dead space wrt baseline A simplified mechanical structure and assembly procedure reduction of costs. Less power line (2 lines vs 7 lines in 3- GEM) cost reduction Well pitch: 140 m Well diameter: 70-50 m Kapton thickness: 50 m Copper top layer (5 m) - DLC layer (<0.1 m) R 50-100 M / 1 2 3 - Plan to have all the production done outside CERN further cost reduction Rigid PCB readout electrode -RWELL PCB Expect cost reduction with respect to baseline ~ 15 % G. Bencivenni et al., 2015_JINST_10_P02008 11

The ME0 Detector Extend muon tagging coverage up to 2.9 and enhance trigger to ~2.4 range using space available in the back of the new endcap calorimeter ME0 baseline is 6 layers of triple-GEMs arranged in 200 super-module wedges: 216 Chambers High granularity spatial segmentation for: Position and bending measurement of the muon stubs for efficient matching of offline pixel tracks. Muon track Multi-layered structure to: improve local muon track reconstruction discriminate muon (segment) against neutrons (uncorr hits). Cost scaled from GE1/1 But still uncertainties in the design of the services pending further work on the layout of all subsystems in the new endcaps. Installation in LS3, EDR Q4 2021: expenditures will start in 2021 12

Costs, INFN interest and contribution INFN CORE INFN CORE TP TP Estimated CORE cost Estimated CORE cost GE21 Station MCHF MCHF ME0 Station MCHF MCHF Chamber assembly 1,7 0,57 Chamber assembly 1,176 0,41 Electronics (DAQ/BE) 0,9 Electronics (DAQ/BE) 1,438 Electronics (FE) 0,501 0,10 Electronics (FE) 0,515 0,11 Power system 0,480 0,48 Power system 0,934 0,33 Services 0,416 Services 0,283 Installation 0,130 Installation 0,176 Total 4,1 1,15 Total 4,5 0,85 INFN involvement and possible commitment in Phase2: Simulation and performance studies -Bari, Pavia, Bologna Chamber production 3-GEM or R- well 2 Production sites (Bari,LNF) - Bari, BO, LNF, PV. Front-end electronics VFAT3 chip for GE2/1 and new design ME0 Bari- Pavia Power system & integration- Napoli - Design and production in collaboration with CAEN engineers Alignment system- Napoli 13

Muon global L1 trigger Interest to contribute to the design of the L1 global muon trigger architecture (PD, Bari, Bologna, ) Architecture / input bandwidth under definition: main cost drivers. INFN Contribution to be defined. 14

Muon Upgrade project Large community: ~ 80 FTE so far expected to be involved in the production, installation, commissioning phase FTE Staff FTE no-staff ricercatori+tecnologi Totale ricercatori+tecnologi GEM RPC DT Grand Total 19,7 9,1 19 47,9 18,4 7,3 5 30,7 38,2 16,4 24 78,6 Large fraction of manpower (~1/3) is no-staff Some key persons (detector construction and electronics (are not staff 15

Muon project summary On- detector electronic s kCHF Power system kCHF Back-end electronics kCHF Optical links kCHF INFN Contribution kCHF TOTAL COST KCHF Detecto r kCHF COMMENT % 41% 23% 0 1326 210 0 872 276 2474 2000 6100 8600 DT GE21+ME0 980 810 21% 286 263 251 800 3800 Phase 1 INFN 2300 KCHF + 1300 KCHF (LINK SYSTEM) GE11 11% 100 50 150 100 400 3600 RPC No INFN contribution CSC 3700 22% TOTALE 1366 1849 1211 972 276 5674 25800 New under definition Trigger L1 200 7300 Note: Power system upgrade for DT not included in CORE costs. 16

Muon upgrade timeline GE1/1 Technical Design Report (TDR) approved as being the first CMS Phase II TDR, following the need of early operation in LS2. Muon TDR Q4-2017: Design and demonstration phases for Detectors and Front-end electronics Upgrade by Q4-2017 CMS upgrade activity optimization requires Anticipation of CSC Front-end upgrade in LS2 Installation of GE2/1 and RE3/1-RE4/1 detectors in Extended Technical Stops before LS3 DT electronics, CSC back-end electronics and ME0 upgrade in LS3 17