LAPPD System Status Report Summary

The LAPPD system has been up and running smoothly since July, with carefully mapped temperature profiles and maintained vacuum levels. Despite minor issues with heaters, the system is stable and producing functional tiles. Maintenance plans include heater replacements and chamber installations. The system has produced functional tiles with varying seal qualities and MCP performances. Repairs and maintenance have been minimal, with the system available for production 90% of the time. Sealing processes have been successful, with a few understood cracks due to specific reasons.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

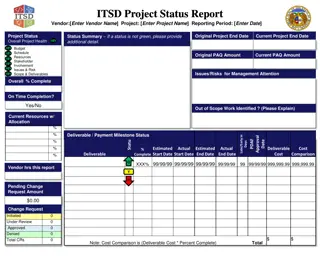

6cm system status System up and running since July Temperature profile carefully mapped out in sealing and deposition chambers Vacuum of major chambers are routinely maintained at 10-9 10-10torr System routinely produce test/functional devices Heater issues 1 (out of two) sealing chamber ceramic heater broke: 1 current lead broke off, which is a know issue with this type of heater 1 (out of two) deposition halogen lamp heater have a back contact after replacing the light bulbs Decided to try continue without repairing any of them Quickly found out running condition (on the 1sttry) without these heaters Currently, system is stable and producing good tiles A major maintenance period is coming up soon Install heaters in bake and scrub chamber Replace sealing chamber ceramic heaters with halogen lamp heaters Replace contact for deposition heaters All parts are ready, waiting for system down time 2

Functional tiles produced so far Serial # 20 21 22 23 24 25 26 27 28 Seal Good Good Good/ Cracked Cracked Good Good Cracked Good Good MCP Gen I Gen I (none) --- Gen I (bad) Gen I (bad) (none) Gen I Gen II Getter Bad Bad Better --- Good Good --- Good Good lifetime 1-2 days 1-2 days 4 days (cracked) --- Since 9/1/14 Since 9/8/14 --- Since 9/17/14 Since 9/24/14 Notes: #22 and #26 are special tiles for QE measurements, with no MCPs in them #24 and #25 didn t produce signal at reasonable HV, due to MCP resistance drop after bake (known early GEN I MCP issue), but the seals are good and the photocathodes remain light brown up to now (originally thought the seals were bad) 3

Remarks: system availability Tile #20 was started on 7/24, and tile #29 will finish on 9/29 In ~10 weeks we produced 10 tiles with the 6cm system Only had minor repair/maintenance/bake out, that took ~ 1 week in total System is available for tile production ~90% of the time Tile processing time is ~ 1 week 4

Remarks: sealing In the last 2.5 months, sealed 15 tiles (5 sealing tests + 10 functional tiles) Other than 5 cracks, all seals are successful All cracks are understood 3 early ones cracked 1 4 days after a good seal was formed: changed fixture #23 was due to a concaved tile base #26 top window was accidentally hit by the sealing block too hard Sealing process is well understood, and carried out with high yield 5

Remarks: getter activation Found one condition that can activated getter reasonably well (produced tiles with extended lifetime) Initially bake/activation at high temperature, but was not successful (1-2 days lifetime) Switched to low T bake + high T activation, so far successful Configured separate vacuum system to optimize getter activation Measure MCP, frit out gas rate Measure getter pumping speed, capacity under different activation conditions System is currently ready, we are preparing test samples 6

Test results of recent tiles Tile #27 MCP: GEN I, reused from tile #21 produced on 9/17/2014 7

Test results of recent tiles Tile #28 MCP: GEN II (latest, high gain) produced on 9/24/2014 12

QE measurement Tile 22 Special tile for QE measurement Produced on 08/08/2014 14

QE of tile #28 A new method is being developed, in order to estimate QE of functioning tiles QE is estimated by comparing to a commercial MCP-PMT with known QE Close to single photon laser pulses are used to illuminate both devices Tile #28 has QE ~11% (with large uncertainty), which agree with in situ measurement 17

Schedule System is currently processing tile #29 and #30 Scenario I Stop tile production after tile #30 Start maintenance period as originally planned Expect better system performance after maintenance But down time could be longer than expected, and it also takes time to figure out new working condition Scenario II Continue tile production until having good number of working tiles in hand (or something significant on the system breaks) Postpone maintenance period for several weeks Might be able to secure enough working tiles for testing at early stage Still need to check part availability for scenario II Will discuss run plan next Monday (9/29) 18