Jigs and Fixtures for Mass Production

Exploring the importance of jigs and fixtures in facilitating easy assembly, reducing unit costs, and ensuring interchangeability in mass production methods. Learn about the definitions, functions, and differences between jigs and fixtures, as well as their roles in guiding cutting tools and holding workpieces securely for accurate operations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

UNIT NO 6 JIGS & FIXTURES

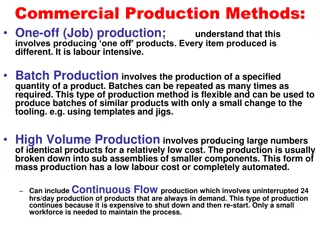

INTRODUCTION The successful running of any mass production depends upon the interchangeability to facilitate easy assembly and reduction of unit cost. Mass production methods demand a fast and easy method of positioning work for accurate operations on it. Jigs and fixtures are production tools used to accurately manufacture duplicate and interchangeable parts. Jigs and fixtures are specially designed so that large numbers of components can be machined or assembled identically, and to ensure interchangeability of components.

DEFINITIONS JIGS : A device that holds the work and locates the path of the tool. Fixture: A device fixed to the worktable of a machine and locates the work in an exact position relative to the cutting tool.

JIGS It is a work holding device that holds, supports and locates the work piece and guides the cutting tool for a specific operation. Jigs are usually fitted with hardened steel bushings for guiding or other cutting tools. A jig is a type of tool used to control the location and/or motion of another tool. A jig's primary purpose is to provide repeatability, accuracy, and interchangeability in the manufacturing of products. A device that does both functions (holding the work and guiding a tool) is called a jig. An example of a jig is when a key is duplicated, the original is used as a jig so the new key can have the same path as the old one.

FIXTURES It is a work holding device that holds, supports and locates the work piece for a specific operation but does not guide the cutting tool. It provides only a reference surface or a device. What makes a fixture unique is that each one is built to fit a particular part or shape. The main purpose of a fixture is to locate and in some cases hold a work piece during either a machining operation or some other industrial process. A jig differs from a fixture in that a it guides the tool to its correct position in addition to locating and supporting the work piece. Examples: Vises, chucks

HOW DO JIGS AND FIXTURES DIFFER JIGS FIXTURES 1. It is a work holding device that holds, supports and locates the work piece and guides the cutting tool for a specific operation 1. It is a work holding device that holds, supports and locates the work piece for a specific operation but does not guide the cutting tool 2. Jigs are not clamped to the drill press table unless large diameters to be drilled and there is a necessity to move the jig to bring one each bush directly under the drill. 2. Fixtures should be securely clamped to the table of the machine upon which the work is done.

JIGS FIXTURES 3. The jigs are special tools particularly in drilling, reaming, tapping and boring operation. 3. Fixtures are specific tools used particularly in milling machine, shapers and slotting machine. 4. Gauge blocks are not necessary. 4. Gauge blocks may be provided for effective handling. 5. Lighter in construction. 5. Heavier in construction.

TWO MAIN TYPES OF JIGS: For machining purposes Locates the component, holds it firmly in place, and guides the cutting tool. For assembly purposes Locates separate component parts and holds them rigidly in their correct positions while they are being connected

USES OF JIG AND FIXTURE Reduce cost of production. Increase the production. To assure high accuracy of parts Provide for interchangeability Enable heavy and complex parts to machine Reduced quality control expenses. Increased versatility of machine tool. Less skilled labour. Saving labour. Partially automates the machine tools Use improve the safety, accidents low

ELEMENTS OF JIG AND FIXTURE Sufficiently rigid bodies (plate, box or frame structure Locating elements. Clamping elements. Tool guiding elements. Elements for positioning or fastening the jig or fixture.

ADVANTAGES OF JIGS AND FIXTURES PRODUCTIVITY: Jigs and fixtures increases the productivity by eliminating the individual marking, positioning and frequent checking. The operation time is also reduced due to increase in speed, feed and depth of cut because of high clamping rigidity. INTERCHANGEABILITY AND QUALITY: Jigs and fixtures facilitate the production of articles in large quantities with high degree of accuracy, uniform quality and interchangeability at a competitive cost .

SKILL REDUCTION: There is no need for skillful setting of work on tool. Jigs and fixtures makes possible to employ unskilled or semi skilled machine operator to make savings in labour cost. COST REDUCTION: Higher production, reduction in scrap, easy assembly and savings in labour cost results in ultimate reduction in unit cost.

FUNDAMENTAL PRINCIPLES OF JIGS AND FIXTURES DESIGN LOCATING POINTS: Good facilities should be provided for locating the work. The article to be machined must be easily inserted and quickly taken out from the jig so that no time is wasted in placing the work piece in position to perform operations. The position of work piece should be accurate with respect to tool guiding in the jig or setting elements in fixture. FOOL PROOF: The design of jigs and fixtures should be such that it would not permit the workpiece or the tool to inserted in any position other than the correct one.

REDUCTION OF IDLE TIME: Design of Jigs and Fixtures should be such that the process, loading, clamping and unloading time of the workpiece takes minimum as far as possible. WEIGHT OF JIGS AND FIXTURES: It should be easy to handle, smaller in size and low cost in regard to amount of material used without sacrificing rigidity and stiffness. JIGS PROVIDED WITH FEET: Jigs sometimes are provided with feet so that it can be placed on the table of the machine. MATERIALS FOR JIGS AND FIXTURES: Usually made of hardened materials to avoid frequent damage and to resist wear. Example : MS, Cast iron, Die steel, CS, HSS.

TYPES OF JIGS AND FIXTURES Template jig Plate jig Diameter jig Leaf jig Channel type jig Clamp jig

TEMPLATE JIG This is the simplest type of jig. It is simply a plate made to the shape and size of the work piece with the require number of holes made it. It is placed on the work piece and the hole will be made by the drill which will be guided through the holes in the template plate should be hardened to avoid its frequent replacement. This type of jig is suitable if only a few part are to be made.

PLATE TYPE JIG This is an improvement of the template type of jig. In place of simple holes, drill bushes are provided in the plate to guide the drill. The work piece can be clamped to the plate and holes can be drilled. The plate jig are employed to drill holes in large parts, maintaining accurate spacing with each other.

LEAF JIG It is also a sort of open type jig in which the top plate is arrange to swing about a fulcrum point so that it is completely clears the jig for easy loading and unloading of the work piece. The drill bushes are fitted into the plates , which is also known as leaf , latch or lid.

CHANNEL JIG The channel jig is a simple type of jig having channel like cross section. The component is fitted within the channel is located and clamped by locating the knob. The tool is guided through the drill bush.

INDEXING FIXTURE Indexing jigs are used to accurately space holes or other machined areas around a part. To do this, the jig uses either the part itself or a reference plate and a plunger. Larger indexing jigs are called rotary jigs.

MILLING FIXTURES A Milling fixture is a work holding device which is firmly clamped to the table of the milling machine. It holds the work piece in correct position as the table movement carries it past the cutter or cutters.

ESSENTIALS OF MILLING FIXTURES Base: A heavy base is the most important element of a milling fixture. It is a plate with a flat and smooth under face. The complete fixture is built up from this plate. Keys are provided on the under face of the plate which are used for easy and accurate aligning of the fixture on the milling machine table. By inserting them into one the T slot in the table. These keys are usually set in keyways on the under face of the plate and are held in place by a socket head cap screw for end key. The fixture is fastened to the machine table with the help of two T bolts engaging in T slots of the work table.

SETTING BLOCKS After the fixture has been securely clamped to the machine table the work piece which is correctly located in the fixture has to be set in correct relationship to the cutters. This is achieved by the use of setting blocks and feeler gauges. The setting blocks is fixed to the fixture In it correct setting , the cutter should clear the feeler surfaces by at least 0.08cm to avoid any damage to the block when the machine table is moved back to unload the fixture. The thickness of the feeler gauge to be used should be stamped on the fixture base near the setting block.

SOME DESIGN PRINCIPLES FOR MILLING FIXTURES: Pressure of cut should always be against the solid part of the fixture(fig a). Clamps should always operates from the front of the fixture (fig B) The work piece should be supported as near the tool thrust as possible(fig c)

DESIGN PRINCIPLES FOR MILLING FIXTURES