Enhancing Workplace Safety Through Safety Kaizen Methodology

Safety Kaizen is a continuous improvement approach focused on identifying and addressing safety hazards to create a safer work environment. It involves steps such as problem identification, root cause analysis, brainstorming solutions, implementing improvements, monitoring progress, and involving em

1 views • 5 slides

Enhancing Performance Management Strategies for Sustainable Growth

Explore concepts like quality-related costs, Kaizen costing, Six Sigma, and the Balanced Scorecard framework to improve financial and non-financial performance evaluation in organizations. Understand the significance of non-financial performance indicators (NFPIs) in measuring productivity, efficien

1 views • 22 slides

Understanding Waste and Kaizen in Toyota Production Systems

Industrial engineers strive to enhance processes by identifying and reducing waste. The concept of waste, known as Muda in Japanese, is central to Lean methodologies. By recognizing and addressing the seven types of waste, such as overproduction and downtime, teams can continuously improve through K

0 views • 7 slides

Workplace Safety Regulations and Kaizen Events

Workplace safety regulations are essential during Kaizen events for productivity and safety improvement. This PowerPoint provides a quick refresher on common safety regulations such as fire extinguisher clearance, accessible walkways, eyewash stations, electrical panel requirements, and more to cons

0 views • 13 slides

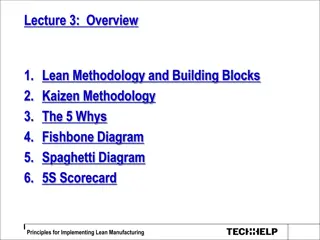

Introduction to Lean Methodology and Tools for Process Improvement

Lean methodology focuses on identifying and eliminating waste in operations to improve efficiency. Key tools such as Kaizen, 5 Whys, Fishbone Diagram, and Spaghetti Diagram are utilized for continuous improvement. The building blocks of Lean include Kaizen, Pull/Kanban, TPM, 5S System, and more. Und

0 views • 8 slides