Innovative Tire Pyrolysis Process at Golden Isles Conservation Center

Golden Isles Conservation Center implements a cutting-edge tire pyrolysis process using advanced technology to decompose tires into valuable components like synthesis oil, carbon black, and synthesis gas. This sustainable initiative aligns with environmental conservation goals set by Cox Enterprises, aiming for zero waste to landfill by 2024 and carbon neutrality by 2044. By utilizing a unique thermal engine and pyrolysis unit, the center efficiently converts waste tires into useful resources while reducing environmental impact.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Golden Isles Conservation Center Tire Pyrolysis Process

Introductions & Background Information Cox Enterprises Cox Conserves Founded 2007 Doing Business can t be separate from doing the right thing $100 million investment in sustainability and conservation through operations, projects and grants to environmental nonprofits Zero waste to the landfill by 2024 Become carbon and water neutral by 2044

Introduction & Background Information continued Seven Islands Environmental Solutions Golden Isles Conservation Center Harbin Engineering, PC Due Diligence Study Technically Sound Financially Viable and Competitive in the Open Market Recommended Proceeding with Technology

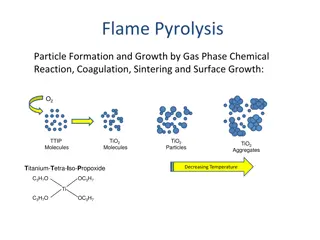

Pyrolysis Defined Definition of Pyrolysis Pyrolysis is a thermochemical decomposition of organic material at elevated temperatures in the absence of oxygen The word is coined from the Greek-derived elements pyro "fire" and lysis "separating". IT IS NOT INCINERATION OR COMBUSTION OF WASTE MATERIAL

GICC TIRE PYROLYSIS PROCESS Two Processes DCS Thermal Engine Waste wood chips are fed into the DCS Thermal Engine to create heat for the process using a proprietary technology. The technology was first created in Italy, and Seven Islands Environmental Solutions is the first company to use it in the US. The exhaust gas from the DCS passes through a titanium catalyst bed housed in the Catalyst Box (C.I.T. Cube) where air pollutants are treated prior to passing through the pyrolysis unit

GICC TIRE PYROLYSIS PROCESS (continued) Pyrolysis Unit (PDG) The pre-shredded tire chips are conveyed to and pass through the PDG in tubes heated from the gases surrounding the tubes from DCS. The heat breaks down the tires into their original components Synthesis Oil Recovered Carbon Black Synthesis Gas Steel

GICC TIRE PYROLYSIS PROCESS (continued) Original components are separated and stored for shipping and re-use Excess Syngas is diverted from the safety flare back into a burner box connected to the PDG. The gas is burned for process heat and the exhaust flows through the catalyst box and into the PDG. It replaces the DCS as a heat source once the process is started, making the process self-sustaining as long as the tire chips continue to be prolysized.

GICC TIRE PYROLYSIS PROCES(continued) A proprietary Hydraulic Water Filter filters particles from the exhaust air stream which results in clean emissions. An Exhaust Stack removes heat and water vapor from the system The Existing GICC Plant daily removes the equivalent of 5 tons per day of tires from landfills and waterways. The existing plant was designed, built, shipped, sited, constructed and operational two years from the date the final decision was made by Cox to proceed!

Future Seven Islands Environmental Solutions (SIES) is working on research to be able to process other feedstocks with this technology. SIES is fine tuning the operational capabilities of the existing 5 ton per day plant. Plans include a larger capacity plant in the years to come.

If you have questions on, or a need for processing tires or other feedstocks please contact: Robert Fairey Sr. Director, Energy Procurement & Waste Diversion Cox Enterprises, Inc. 6205 Peachtree Dunwoody Rd. Atlanta, GA 30328 Phone: (678) 645-0634 Mobile: (770) 241-5621 Email: Robert.fairey@coxinc.com

Questions? My Contact Information: Steve Harbin, P.E. HARBIN ENGINEERING, P.C. 41 West Johnston Street Forsyth, Georgia 31029 (478) 747-2512 cell (478) 992-9122 office (478) 994-0439 fax sharbin@harbinengineering.com