Guidelines for Effective Management of Fertilizer Movement and Quality Control

Regular stock reconciliation, monitoring of dealer transactions, curbing hoarding practices, timely submission of subsidy claims, and strict quality control measures are essential for efficient management of fertilizer movement. Special emphasis on monitoring sales prices and ensuring compliance with regulations is crucial to prevent black marketing. Close attention to quality control procedures, including sample drawl and legal action against non-standard samples, is necessary to maintain quality standards.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

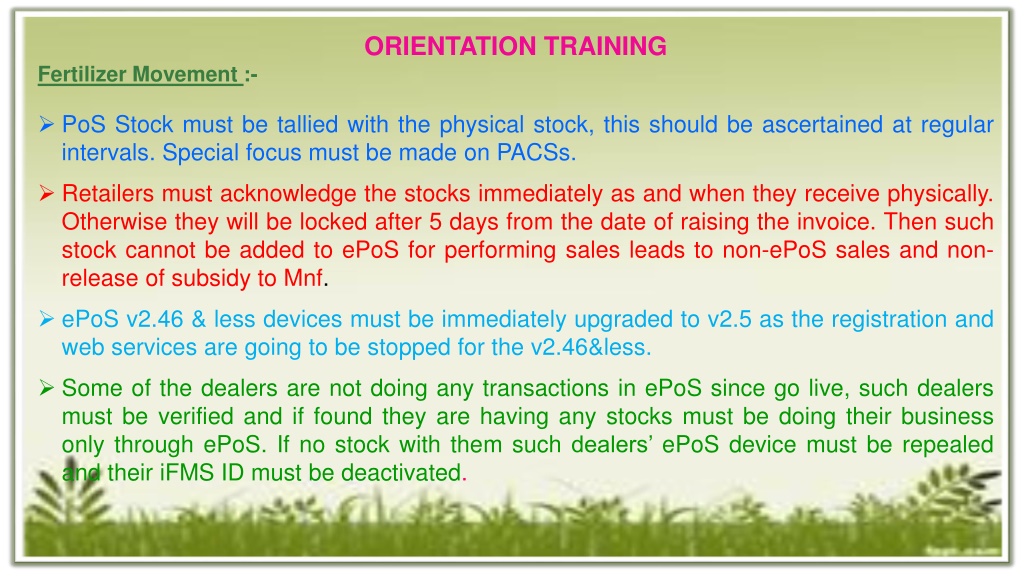

ORIENTATION TRAINING Fertilizer Movement :- PoS Stock must be tallied with the physical stock, this should be ascertained at regular intervals. Special focus must be made on PACSs. Retailers must acknowledge the stocks immediately as and when they receive physically. Otherwise they will be locked after 5 days from the date of raising the invoice. Then such stock cannot be added to ePoS for performing sales leads to non-ePoS sales and non- release of subsidy to Mnf. ePoS v2.46 & less devices must be immediately upgraded to v2.5 as the registration and web services are going to be stopped for the v2.46&less. Some of the dealers are not doing any transactions in ePoS since go live, such dealers must be verified and if found they are having any stocks must be doing their business only through ePoS. If no stock with them such dealers ePoS device must be repealed and their iFMS ID must be deactivated.

Fertilizer Movement :- Some of the dealers are issuing stocks to some farmers in huge quantities, such practices must be curbed immediately otherwise such practices may lead to hoarding & black marketing. Frequent buyers must be discouraged otherwise such practices may lead to hoarding & black marketing. Monitoring the sale of Fertilizers at not more than the fixed MRPs.

Fertilizer Claims :- Pending subsidy claims should be submitted duly paying personal attention as they are pending since Nov-2012 in SSP, Oct-2016 in Urea and July-2016 in P&K. In case of Urea and P&K fertilizers, the Quantity certificates (B1) should be sent immediately followed by Quality certificates (B2) as and when the samples results are received along with Form-J and L s. Sampling in SSP manufacturing units should be done month-wise, in that particular month only @one sample /150-200 M.Ts. The JDA s should inspect the SSP-manufacturing units every month and certify the batches produced from which the samples drawn in that particular month. If there is delay in inspection for more than one month it will not be accepted. In case of SSP manufacturing units, every lot/batch produced should be kept separately for curing. It should not be mixed/heaped with the other batch/lot. Like-wise every batch produced should be sampled after curing and let the production be dispatched after receiving the standard results. This should be done strictly as and when the product is ready for sampling and should be done every month and for every batch/lot produced. In case of City Compost the JDA s should instruct their QCI s to take action and draw the samples as per the FCO and also submit B1&B2 reports.

Fertilizer Quality Control :- 1. Drawl of category wise samples specifically NPK Granulated mixtures, micronutrients, Bio and Organic fertilizers as per targets communicated. 2. Initiation of action on Non-standard samples and filing of legal cases in the court of law as early as possible. The district JDAs should monitor closely on above aspects regularly. General Observations and common mistakes observed in quality control of fertilizers: a. Non-drawl of NPK Granulated mixtures, Bio and Organic fertilizers by the Fertilizer Inspectors even said categories available at dealer outlets. b. It is observed that, all the samples drawn at manufacturing units by the concerned Fertilizer Inspectors are found standard, whereas the same batch numbers drawn at dealer points are failing in Nutrient content with wide variation which casts doubt on the sampling procedures at the manufacturing units.

Fertilizer Quality Control :- c. Wide variation in 1st analysis and 2nd analysis, which casts doubt on whole sampling procedures. d. Failure/delay in seizure of stocks after non-standard in Re-analysis. e. Drawl of non-notified fertilizers and fertilizers which are not according to specifications of FCO, 1985. f. Delay in sending samples to the Fertilizer Coding Center for analysis. g. Badly delay in serving of form Ls to dealers/manufacturers. h. Lack of monitoring on carrying of fertilizer business by the dealers even after expiry of validity of source (Form O). i. Non submission of fourth portion samples of NPK granulated mixtures, SSP and Micronutrients.