Ford New Holland Front Attachments for CM Series Tractors Operator’s Manual Instant Download (Publication No.42647000)

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

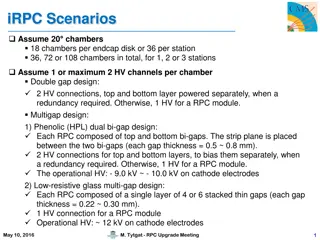

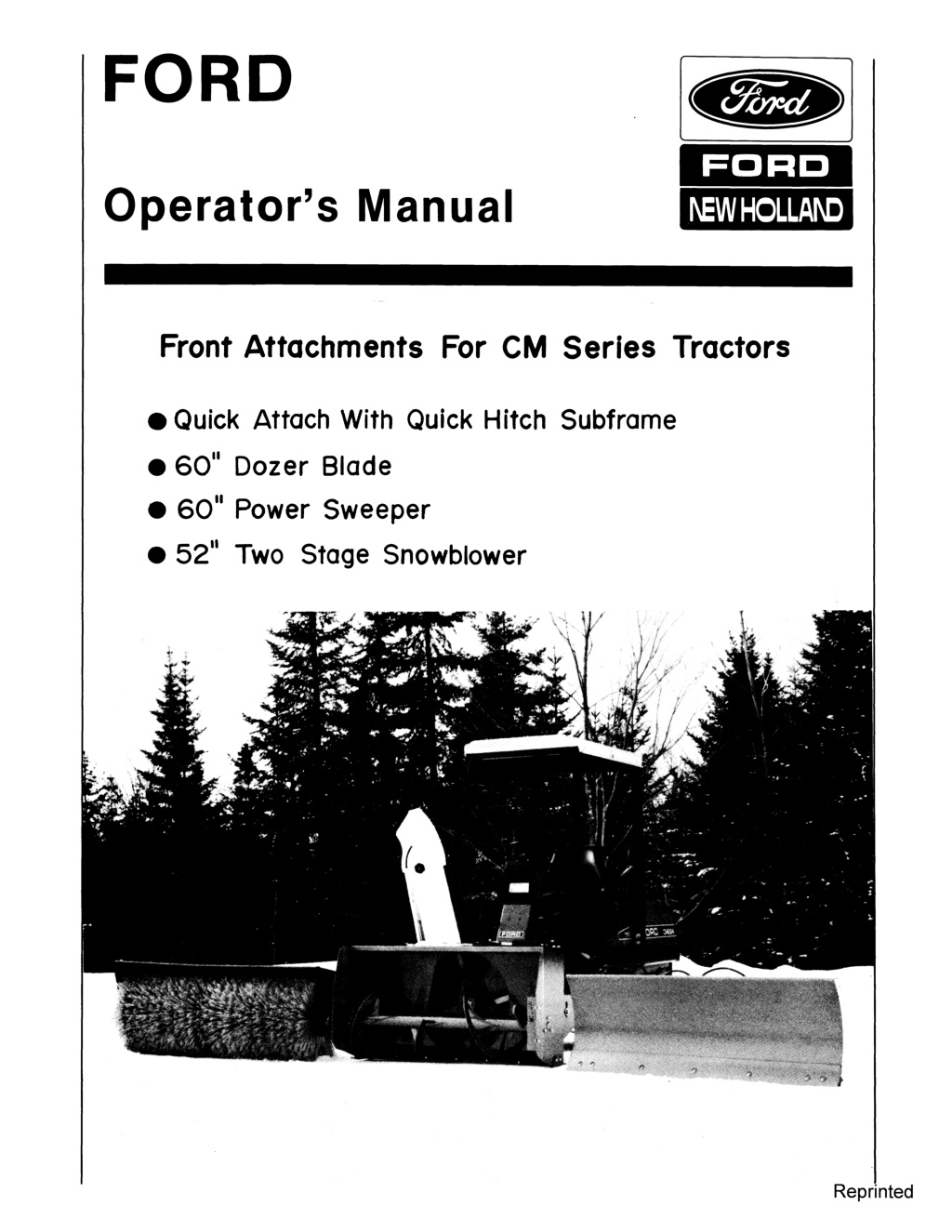

FORD FORD Operator's Manual I \ E W H O L L A ~ Front Attachments For eM Series Tractors Quick Attach With Quick Hitch Subframe 60" Dozer Blade 60" Power Sweeper 52" Two Stage Snowblower Rep

OWNER ASSISTANCE We at Ford New Holland, Inc. and your Ford New Holland Dealer want you to be completely satisfied with your investment. Normally any problems with your equipment will be handled by your dealer's Service Department. Sometimes, however, misunderstanding can occur. If your problem has not been handled to your satisfaction, we suggest the following: 1. Contact the owner or General Manager of- the dealership, explain the problem, and request assistance. When additional assistance is needed, your dealer has direct access to our branch office. 2. If you cannot obtain satisfaction by doing this, contact the Ford New Holland, Inc. branch office in your area and provide them with: Your name, address and telephone number Machine model and serial number Dealership name and address Machine purchase date and amount of use Nature of problem New Holland, Pennsylvannia 500 Diller Avenue New Holland, PA Telephone: (717) 355-3950 Calgary, Canada Box 1616, Main P.O. Calgary, Alberta T2P-2M7 Telephone: (403) 569-3200 Atlanta, Georgia 2000 Mountain Ind. Blvd. Tucker, GA Telephone: (404) 491-3471 17557 30084 San Francisco, California 2400 Cordelia Road Fairfield, CA Telephone: (707) 423-9200 Dallas, Texas P.O. Box 10227 Dallas, TX Telephone: (214) 939-4950 Toronto, Canada 600 Southgate Drive P.O. Box 3610 Guelph, Ontario N1H-6P1 Telephone: (416) 457-2720 94533 75207 Kansas City, Kansas P.O. Box 14550 Lenexa, KS Telephone: (913) 894-3300 Detroi t, Michigan 1315 Coolidge Avenue Troy, MI 48084 Telephone: (313) 637-7200 Minneapolis, Minnesota P.o. Box 1342 Minneapolis, MN Telephone: (612) 887-4201 66215 55440 3. If you need further assistance contact: Consumer Services Department Mail Station 500 Ford New Holland, Inc. New Holland, PA Telephone: (717) 355-1545 17557 When contacting Ford New Holland Inc.'s Branch Office or Consumer Services department, be aware that your problem will likely be resolved in the dealership, using his facilities, equipment and personnel, so it is important that your initial contact be with your dealer.

TABLE OF CONTENTS .......................................................... PAGE INTROD,UCTION SAFETY PRECAUTIONS .................................................... 2 3 QUICK ATTACH SUBFRAME WITH QUICK HITCH SYSTEM Subframe installation Safety and instructional decals .................................... 6 6 60" DOZER BLADE OPERATION - Operating controls and adjustments MAINTENANCE ASSEMBLY Step 1: Step 2: Blade installation ...................................................... . ...................................................... . Blade assembly 7 8 9 10 11 12 DISMOUNTING SAFETY DECALS ...................................................... 52" TWO STAGE SNOWBLOWER OPERATION Preparing for snow .removal Operating controls and adjustments Snow removal methods ...................................................... . Step 1: Step 2: Step 3: Snowblower installation SAFETY DECALS ...................................................... 13 13 14 15 16 18 20 22 23 MAINTENANCE ASSEMBLY Snowblower assembly Hydraulic chute rotation DISMOUNTING 60" POWER SWEEPER OPERATION Operating controls and adjustments Preparing for sweeping General Brush replacement Step 1: Sweeper preparation Step 2: Sweeper installation Step 3: Optional gauge wheel installation DISMOUNTING ...................................................... . SAFETY DECALS ATTACHMENTS SPECIFICATIONS ............................................ 24 25 26 27 28 28 31 32 33 MAINTENANCE ASSEMBLY 34 ASSEMBLY REFERENCE DRAWINGS 60" Dozer Blade ..................................................... 60" Power Sweeper.................................................... 52" Two Stage Snowblower Chute with Deflector Subframe ............................................................ Hydraulic rotation 35 36 38 40 40 41 HARDWARE TIGHTENING TORQUES Inch Hardware and Locknuts Metric Hardware and Locknuts 42 43 OM0142

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

INTRODUCTION TO THE PURCHASER These new attachments were carefully designed to give years of dependable service. This manual has been provided to assist in the safe operation and service of YOt attachment. All photographs and illustrations in the manual may not necessarily depic the actual models or equipment, but are intended for reference only and aI based on the latest product information available at the time of publicatior NOTE: Familiarize yourself fully with the safety recommendations and operating procedurE before putting the machine to use. Carefully read, unders tand and follow recommendations and insist that they be followed by those who work with you. A THIS SAFETY ALERT SYMBOL IDENTIFIES IMPORTANT SAFETY MESSAGES IN THIS MANUAl WHEN YOU SEE IT, BE ALERT TO THE POSSIBILITY OF PERSONAL INJURY AND CAREFULI READ THE MESSAGE THAT FOLLOWS. t h e ~ Record your attachment model and serial number. ation to give you prompt, efficient service when ordering parts or Service with genuine FORD NEW HOLLAND parts when replacement parts are required. Your dealer requires this inforn a t t a c h m e n t ~ Right hand and left hand are determined by sitting on the tractor seat facing forwarc MODEL SERIAL NUMBER DATE PURCHASED o o FORD NEW HOLLAND INC. NEW HOLLAND. PENNSYLVANIA MODEL NO. SERIAL NO. FDRD COMPONENT o o MADE IN CANADA THE SERIAL NUMBER PLATE IS LOCATED ON EACH ATTACHMENT. ON AND SHOULD NOT BE REMOVED. IT IS RIVETED OM0142 2

SAFETY PRECAUTIONS WHENEVER YOU SEE THIS SYMBOL A A CAREFUL OPERATOR IS THE BEST OPERATOR. MOST ACCIDENTS CAR BE AVOIDED BY OBSERVING CERTAIN PRECAUTIONS. FOLLOWING PRECAUTIONS BEFORE OPERATING THESE ATTACHMENTS TO HELP PREVENT ACCIDENTS. EQUIPMENT SHOULD BE OPERATED ONLY BY THOSE WHO ARE RESPONSIBLE AND INSTRUCTED TO 00 SO. READ AND TAKE THE IT MEANS: THE ATTACHMENT (S) ATTENTION! Read this manual carefully to acquaint yourself with the attachment (s). Working wi th unfamiliar equipment can lead to accidents. Be thoroughly familiar with the controls and proper use of the equipment. Know how to stop the unit and disengage the controls quickly. Keep all Shields in place and properly tighten all mounting hardware. Periodically inspect all moving parts for wear and replace with authorized service parts if an excessive amount of wear is present. Replace all missing, illegible, or damaged safety and warning decals. See list of decals at the end of this manual. Do not modify or alter this equipment or any of its components, or any equipment function without first consulting a Ford New Holland dealer. Keep safety decals clean of dirt and grime. 1. BECOME ALERT! YOUR SAFETY IS INVOLVED! 2. 3. A DANGER 4. ~ e signal word -DANGER- signifies of extreme danqer to a ear a machine exists as ery nature of the machine itself. anqer to persons is such that it would esul t in a hiqh likelihood of death or ermanent injury if the recoow!nded precautions ["e not taken. that a person on or a result of the ~ u r c e 5. This 6. GENERAL PREPARATION A WARNING Be sure the PTO is in OFF posi tion before starting the engine. Clothing worn by the operator should be fairly tight and belted. Loose clothing should not be permitted because of the danger of getting into moving parts. Prolonged exposure to loud noise can cause impairment or loss of hearing. Wear a sui table hearing protective device such as'earmuffs or earplugs to pro tec t agai ns t uncomfortable noises. 1 2. ne signal word WARNING- indicates ource of danqer to a person on achine exists which may r injury if the recommended precautions re not taken. that a or near a 3. result in death obj ectionable or OM0142 3

SAFETY PRECAUTIONS 1 8. Never operate machine at high transpo rt speeds on a slippery surface. 19. Use care when backing up. 20. After striking a foreign object, stop the engine, wait for all movements to stop, thoroughly inspect the attachment for damage and repair the damage before restarting and operating the attachment. 21. If the swepper or snowblower should start to vibrate abnormally, stop the engine immediately and check for the cause. Vibration is generally a warning of trouble. 22. Do not clear snow across the face of slopes. Exercise extreme caution when changing direction on slopes. attempt to clear steep slopes. OPERATING THE ATTACHMENT(S) THE FOLLOWING PRECAUTIOIIS ARE SUGGESTED BEFORE OPERATING EACH OF THESE ATTACHMENTS TO HELP PREVENT ACCIDENTS. Never allow anyone to ride on the attachment. Clear the area of people and debris before commencing operation. Never allow children to operate equipment. Never allow adul ts to operate equipment without proper instruction. Always keep the attachment discharge directed away from people and objects which could be struck by debris. Never allow anyone in front of unit. Never leave attachment in raised position. Never operate the attachment without good visibility and lighting. Never clean or adjust P'ID-driven equipment with the tractor engine running. When operating PTO-driven equipment, always shut off the engine and wait for the PTO to stop turning before getting off the tractor, before unplugging the collector/impeller housing or discharge guide and before making any repairs, adjustments or inspections. 10. Take all, poss ible precautions when leaving the vehicle unattended. Disengage the PTO, lower the attachment, shift into neutral, set the parking brake, stop the engine and remove the key. 11. Disengage power to attachment when transporting or when not in use. 12. The operator should never get off the tractor while it is in motion. 13. Exercise extreme caution when operating on or crossing gravel drives, walks or roads. Stay alert for the hidden hazards of traffic. 14. Do not put hands or feet near rotating parts. Keep clear of discharge opening at all times. 15. Do not use hands or feet to unplug spout. 16. Keep a careful watch for debris that could enter the blower while operating. 17. Never operate the attachment without guards, shields and other safety protective devices in place. 1. 2. 3. 4. Do not 5. 6. 7. THE TRACTOR 8. 1. Read the Operator's Manual carefully before using tractor. Lack of operating knowledge can lead to accidents. Always use an approved rollbar and seat belt for safe operation. Overturning a tractor without a rollbar can result in death or injury. If your tractor is not equipped with a rollbar and seat belt, see your Ford New Holland dealer. Always use the seat belt when the rollbar is installed. Do not use the seat belt if the rollbar is removed from the tractor. Use the handholds and step plates when getting on and off the tractor to prevent falls. Keep steps and platform cleared of mud and debris. Do not permit anyone but the operator to ride on the tractor. safe place for extra riders. 9. 2. 3. 4. 5. There is no OM0142 4

SAFETY PRECAUTIONS MAIHTEHAHCE AND STORAGE OPERATING THE TRACTOR Provide adequate blocking before working under an attachment when in raised position. Escaping hydraulic/diesel fluid under pressure can penetrate the skin causing serious injury. Never start the engine while standing beside the tractor. Always sit on the tractor seat while starting the engine or operating controls. Never run the tractor engine in a closed building without adequate ventilation as the exhaust fumes are very dangerous. Always set the hydraulic selector lever in Position Control when attaching equipment, transporting equipment and when no equipment is attached. Never allow an open flame near the fuel tank or battery. Use an SMV emblem and the flasher warning lamps when traveling on public roads, day or night, unless prohibited by law in your state. Make sure the PTa shield is installed when using PTa-driven equipment and always replace the PTa shield if damaged. Always bring the tractor to a complete stop and shut off the engine before getting off the tractor. Never park the tractor on a steep incline. Use care when operating on steep grades to maintain proper stability. Keep the. tractor in gear when going downhill. Use of tire chains and wheel weights for better traction and stability is recommended. See Tractor Manual for recommended weighing. 12. Always drive the tractor at speeds compatible with safety, especially when operating over rough ground, crossing ditches, or when turning. 13. Handle fuel with care as it is highly flammable. a) Use approved fuel container. b) Never add fuel to a running engine or a hot engine. c) Fill fuel tank outdoors wi th extreme care. Never fill fuel tank indoors. d) Replace fuel cap securely and wipe up spilled fuel. 1. 1 2. 2. DO NOT use your hand to check for leaks. Use a piece of cardboard or paper to search for leaks. Stop engine and relieve pressure before connecting or disconnecting hydraulic or diesel lines. Tighten all connections before starting engine or pressurizing lines. If any fluid is injected into the skin, obtain medical attention immediately or gangrene may result. 3. 4. 5. 6. 3. Make certain all moving parts have stopped before cleaning, repairing or inspecting. Do not run engine indoors. Do not attempt to repair or tighten hydraulic hoses when under pressure, when the tractor engine is running, or when the attachment is raised. 7. 4. 5. 8. 9. 1 O. 11. OM0142 5

ASSEMBLY \ QUICK ATTACH SUBFRAME WITH QUICK HI'-'CH SYSTBl SUBFRAME INSTALLATION BEFORE INSTALLING THIS SUBFRAME MAKE SURE ENGINE IS OFF AND PARKING BRAKE IS SET. a) Insert subframe (fig.1, item 1) in tractor attachment tubes (fig.1, item 2). Secure both sides of subframe to tractor with pins (fig.1, item 3) and hairpins from tractor. FIGURE 1 SAFETY AND INSTRUCTIONAL DECALS REPLACE DlMEDIATELY IF DAMAGED (See your Ford New Holland dealer) ATTACHING INSTRUCTIONS 1. Insert subframe into attachment completely. 2. Lpck in place by moving lever forward to "Lock" position and secure with linch pin. 3. If equipped with P.T.O. drive line, connect to trac- tor P.T.O. and lock in place. 4. If equipped with lift assist springs, lift the attach- ment a,nd attach springs. UNLOCK ( --r-__ ~ ---...J-._ -- BER-657364 A DANGER LOCK 113 CiLAR LOCK <J [> UNLOCK ~ 1 l l C : TO AVOID SERIOUS PERSONAL INJURY WHEN ATTACHING OR DETACHING IMPLEMENT SHUT OFF TRACTOR AND REMOVE KEY WHEN DEl ACHING REMOVE DRIVE LINE FROM TRACTOR . WHEN ATTACHING MAKE SURE ATTACHMENT DRIVE LINE COLLAR IS PROPERLY LOCKED TO TRACTOR P.T.O. 119 OM0142 6

OPERATION 60 DOZER BLADE OPERATING CONTROLS 1. RAISING AND LOWERING FRONT BLADE The hydraulic lift lever is located on the right hand side of the tractor. Pulling the lever backwards raises the f ron t blade, pushing the lever forward lowers the front blade and pushing the lever fully forward sets the blade in f loa t position. 2. HYDRAULIC ANGLING The hydraulic angling lever is located on the right hand side of the tractor seat. Pushing the lever forward turns the blade in a counterclockwise direction and pulling the lever backwards turns the blade in a clockwise direction. ADJUSTMENTS WARNING: Before makinq any adjustment, turn enqine off and set parkinq brake. RIGID BLADE OPERATION 1 CAUTION: qround speeds up to 2 mph. Use riqid blade only for low Tb obtain rigid blade operation, move the trip spring lockout brackets (fig.1, i b::!m 1) to the lower holes, hooking over the blade frame. Attach in place with the 3/8" x 1 7/16" pins and secure with 4mm 80mm hairpins. x 2. SKID SHOE ADJUSTMENT Raise blade to transport position. Remove the linchpin (fig.1, item 2) from both skid shoes (fig.1, item 3). Remove or add shim washer (s), placing washers on under side of support brackets for more clearance (there must always be at least one shim washer on top side of support bracket). Reinstall linchpins. FIGURE 1 OM0142 7

MAINTENANCE 60 DOZER BLADE MAINTENANCE 1. Remove dirt from pivot points and angling cylinders every 4 hours of operation, especially in cold weather. Lubrication 1. Grease the fitting at the rod end of each cylinder every 8 hours of operation. 2. Oil all moving parts every month. Before storage 1. Clean the blade thoroughly. 2. Repaint all parts from which paint has worn. 3. When the blade is dry, oil all moving parts. Apply oil liberally to protect against rust. Store blade in a dry place. 4. 8 OM0142

ASSEMBLY STEP 1: BLADE ASSEMBLY a) Ins tall the fema le quick hi tch (fig. 1 , item 1) inside the blade attachment (slot on top side) using a 23/32" dia. x 4 11/16" long pin (fig.1, item 2). Lock the pin in place wi th a 1/4" x 1 1 /4" roll pin on the underside of the blade attachment. b) Install grease fitting (fig.1, item 3) on pin (fig.1, item 2). c) Hook one end of the two springs to the attaching brackets (fig. 2, item 1) on the blade frame. Place a 5/16" x 5" eye bolt (fig.2, item 2) on the other end of each spring. Insert the eye bolts through the holes in the upper blade cross member (fig.2, item 3) as shown in figure 2. Secure the eye bolts with 5/16" nuts. Adjust eye bolts so that the spring lengthens 3/4". Lock eye bolts with two other 5/16" nuts. FIGURE 1 d) Place four shim washers (fig.1, item 4) over each skid shoe (fig.1, item 5). Insert one skid shoe in each support bracket from underside. Place two shim washers over each skid shoe on top side of support bracket and secure skid shoes with linch pins (fig.1, item 6). FIGURE 2 e) Install the trip spring lockout brackets (fig.1, item 7) in the upper holes behind the blade. Lock in place with the 3/8" x 1 7/16" pins and the 1/8" x 2 9/16" hairpins. OM0142 9

ASSEMBLY HYDRAULIC ANGLING INSTALLATION f) Install base end of the two cylinders on the blade (cylinder ports on top side) using two 3/4" x 3 1/4" pins (fig.3, item 1). Lock the pins on the underside with 1/4" x 1 1/4" roll pins. g) Place a breather plug (fig.3, item 2) in the rod end port of each cylinder using thread sealant. h) Attach rod end of each cylinder to the female quick hitch (grease fi ttings outwards) using the 3/4" x 3" pins (fig. 3, item 3). Lock the pins on the upper side of the female quick hi tch with 1/4" x 1 1/4" roll pins. FIGURE 3 i) Using thread sealant, attach a 900 elbow 3/8" male x 1/4" pivoting female and male quick coupler (not included) with rubber dust cap at the 1/4" end of each hose, placing the rubber dust cap ring on the hose before connecting. j) Install the other end of the 53" hose to the base end port of the left hand cylinder (fig. 3, item 4) using thread sealant. Attach the other end of 40" hose to the base end port of right hand cylinder (fig.3, item 5) using thread sealant. STEP 2: BLADE INSTALLATION a) Insert the male quick hitch section (fig.4, item 1) on the tractor into the blade female quick hitch (fig.4, item 2) turn engine off and set parking brake. Lock in place by moving the lever (fig.4, item 3) to lock position (fully forward). Secure latch wi th linchpin (fig.4, item 4). FIGURE 4 10 OM0142

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

ASSEMBLY ~ WARNING: under pressure can penetrate the skin causing serious injury. - Do not use your hands to check for leaks. Use a piece of cardboanl or paper to search for leaks. Stop engine and relieve pressure befon! connecting or disconnecting lines - Tighten all connections before start:ing engine or pressurizing lines. If any fluid is injected into the skin, obtain medical attention immediately or gangrene may result. Escaping hydraulic/diesel fluid b) Connect left hand cylinder hose to the rear female quick coupler, and the right hand cylinder hose to the front female quick coupler on the right hand side of tractor. c) If blade hydraulic angling movements are as described in the blade operating control section on page 7, identify blade hydraulic hoses in relation to female quick couplers using the colored plastic rings. DISMOUNTING a) Set tractor parking brake, stop engine and remove ignition key. Place lift lever in float position and relieve hydraulic pressure by moving valve handles back and forth. b) Remove linchpin (fig.4, item 4) from the quick hitch latch. c) Move the quick hi tch lever (fig.4, item 3) to the unlock position (rearward). Disconnect blade cylinder hoses from tractor. d) Remove blade from subframe. OM0142 1 1

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com