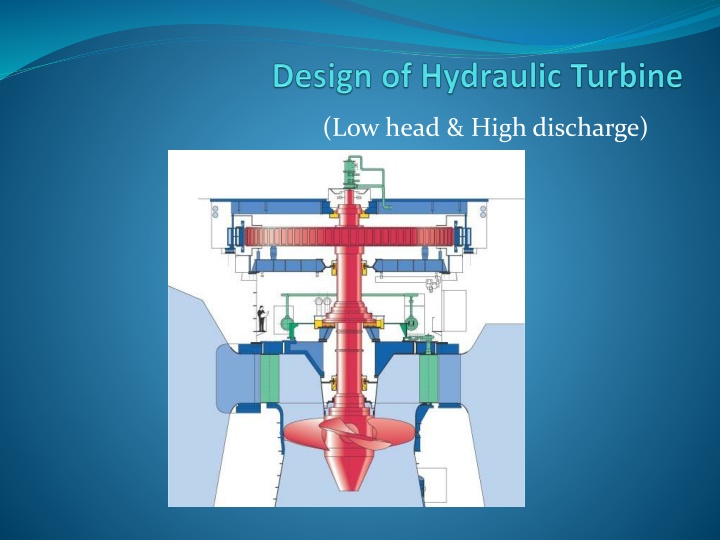

Design and Analysis of Kaplan Turbine for Low Head and High Discharge

The objective of this project is to design and analyze a hydraulic turbine suitable for low head and high discharge conditions, specifically focusing on a Kaplan Turbine. The design considerations include blade profile, power output, specific speed, and turbine selection. Basic calculations and velocity calculations are also performed to determine various parameters for the turbine design.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Objective Design and analysis of Hydraulic turbine for low head and high discharge ( H 10 to 50 m & Nq 70 to 300 rpm) Design of Kaplan Turbine which is most suitable for available head and discharge ( Head = 15m , Discharge Q = 0.9m3/sec). Design of Blade profiledepending on parameters. To fullfill low power requirement in remote areas for general use of electricity (Below 150 Kw)

Chart to determine selection of turbine.

Introduction : Kaplan Turbine Water flows parallel to axis of rotation of shaft turbine is known as axial flow turbine. Kaplan turbine is alsoa reaction turbine. ( partof pressureenergy is converted to kinetic energyduring flow of water). Vanes are fixed on hub and hence hub act as runner for axial flow reaction turbine. In kaplan turbine, unlike all other turbines, the runner's blades are movable. The radial component of the fluid velocity is negligible. Since there is no change in the direction of the fluid, several axial stages can be used to increase poweroutput

Basic Calculations Q = 0.9m^3/sec = 900 lts/sec. H = 15m Turbine speed = 900 rpm. Power Output = Rho x g x QH = 133Kw Specific Work w = gH = 147.15 J/kg Kinematic or specific speed = 112rpm The expected range of specific speed values is 70 < nq < 300. If the specific speed is less than 70, then you should look at an alternative type of turbine e.g. Crossflow ,pump as turbine. Kug(From Graph) = 1.31 [Dh /Dt] (From Graph) = 0.58 Dt outer dia of runner = 0.476 m & Dh hub dia = 0.276 m Blade no (Z) = 6

Dimensions: Drunner Dhub

Velocity Calculations Axial Velocity pi[(Rt)^2 (Rh)^2] x Vf = Q Vf1 = Vf2 = 7.61m/sec (for axial flow machine) Peripheral velocity at inlet and outlet u = [pi x Dh x N]/60 u1 = u2 = 13 m/sec Whirl velocity at inlet and outlet Vw1 & Vw2 x w = u(Vw1 Vw2) (Hydraulic eff) = 0.85(anderson specific speed correction factor) 0.85 x 147.15 = 13(Vw1) Vw1 = 9.62 m/sec Vw2 = 5% Vw1 = 0.481 m/sec

Angle calculations = 51.66 = 23.94 = 3.7 = 58.70

Further project work Blade profile design. Runner(Plate blade design). Spiral casing design. Catia model. Analysis of model.