TURBINE ROTOR SHAFT GRINDING

Mpa Power Project's turbine rotor shaft grinding service offers the pinnacle of precision engineering. To guarantee optimum performance and longevity, our qualified specialists carefully polish the turbine rotor shafts to precise standards. We expertly restore worn-out or damaged rotor shafts to perfect condition using cutting-edge tools and cutting-edge methods, improving power generation's dependability and efficiency. You can rely on Mpa Power Project to maintain your turbine rotor with unmatched skill and attention to detail, producing results that exceed industry standards.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

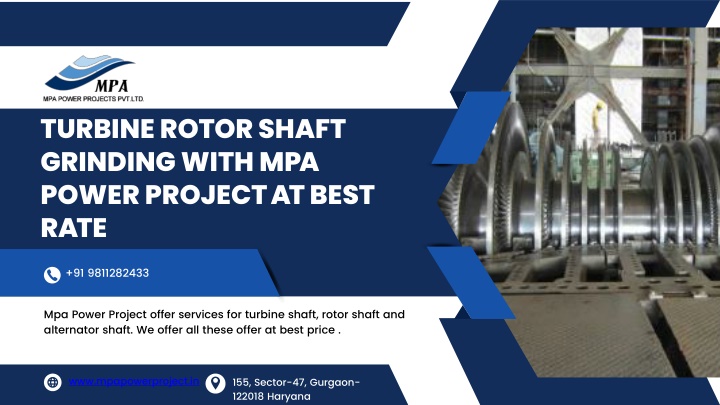

TURBINE ROTOR SHAFT GRINDING WITH MPA POWER PROJECT AT BEST RATE +91 9811282433 Mpa Power Project offer services for turbine shaft, rotor shaft and alternator shaft. We offer all these offer at best price . www.mpapowerproject.in 155, Sector-47, Gurgaon- 122018 Haryana

MPA POWER PROJECT Welcome to MPA Power Project, where craftsmanship meets innovation. For over a decade, our dedicated team of engineers and technicians has been at the forefront of engine repair and overhauling. Specializing in in-situ grinding, we've honed our skills to perfection, adapting to the ever-evolving landscape of technological advancements and industry demands. Join us in shaping the future of engine repair, where every challenge is an opportunity to showcase our passion for excellence.

WHAT IS TURBINE ROTOR SHAFT GRINDING? Turbine rotor shaft grinding is a precision engineering process critical to maintaining the efficiency and reliability of turbine systems. This involves carefully grinding the surface of the shaft to remove imperfections, rust or damage that could compromise performance. This process demands high precision and expertise to ensure that the shaft maintains its dimensional integrity and balance. At MPA, we don't just meet expectations; we exceed them. Our commitment to continuous improvement drives us to enhance our expertise and develop cutting-edge tools and techniques in-house.

HOW MPA POWER REPAIRS TURBINE JOURNALS THAT HAVE FAILED ONSITE MPA POWER PROJECT WORKS 1. Inspection of shaft for crack detection, hardness check and surface finish test. 2. Tolerances in terms of roundness and concentricity are maintained within OEM specification resulting in minimizing of vibrations. 3.Surface finish achieve better than 0.30 um Ra 4.We cover turbine journal diameter having range of 90mm to 550mm

WE REPAIR THE TURBINE JOURNALS THAT HAVE SUFFERED A FAILURE ONSITE, USING OUR ORBITAL TURNING AND GRINDING EQUIPMENT

WE REPAIR THE TURBINE JOURNALS THAT HAVE SUFFERED A FAILURE ONSITE, USING OUR ORBITAL TURNING AND GRINDING EQUIPMENT

OUR OTHER SERVICES IN-SITU GRINDING OF CRANKSHAFT TURBINE ROTOR SHAFT GRINDING REPAIR AND OVERHAUL OF ENGINES LINE BORING AND REPAIR COMPRESSOR SHAFT GRINDING METAL STITCHING OF ENGINE BLOCK AND CAST IRON CONNECTING ROD REPAIR REBABBITTING OF BEARING SPARE PARTS SUPPLY AND EXPORT

CONTACT US +91 9811282433 info@mpapowerproject.in www.mpapowerproject.in 155, Sector-47, Gurgaon Haryana, India

THANK YOU www.mpapowerproject.in 155, Sector-47, Gurgaon