Computer-Controlled Manufacturing Systems Overview

This document outlines the schedule and details for the IENG 475 course on Computer-Controlled Manufacturing Systems. It includes lab schedules, team assignments, lab procedures, and project documentation guidelines. Students are required to attend labs on time, complete assignments, and maintain a lab notebook. The primary goal is to work on projects and demonstrate proficiency in manufacturing operations using computer-controlled systems.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

IENG 475 - Lecture 02 Manufacturing Operations 10/1/2024 IENG 475: Computer-Controlled Manufacturing Systems 1

Agenda Lab Schedule Lab Planning CAD CAM Software Manufacturing Background Questions & Issues 10/1/2024 2 IENG 475: Computer-Controlled Manufacturing Systems

Tuesday 12:00 PM Lab 1 Fitzgerald, Jacob Galuteria Soares, Quentin Jeans, Eli Knott, Katharine Rogers, Summer Steffeck, Samantha 10/1/2024 3 IENG 475: Computer-Controlled Manufacturing Systems

Tuesday 2:00 PM Lab 2 Akunna, Bryan Bano-Sanoguera, Antonio Kliche, Alexandra Leonhardt, Hans Schimbeno, Emily Winger, Owen 10/1/2024 4 IENG 475: Computer-Controlled Manufacturing Systems

Tuesday 4:00 PM Lab 3 Cowart, Dorian Herring, Preston Kringen, Alex Lormeus, Edensky Mattheis, Alex 10/1/2024 5 IENG 475: Computer-Controlled Manufacturing Systems

Thursday 12:00 PM Lab 4 Engelmann, Thomas Li, Ryan Pepke, Steven Pluimer, Cliff Ritchie, Nicholas Young, Grayson 10/1/2024 6 IENG 475: Computer-Controlled Manufacturing Systems

Thursday 2:00 PM Lab 5 Bonzell, Garrett Courtney, Cooper Fiala, Kaitlyn Martinez, Leonardo Ottman, Alyssa Salley, Jace 10/1/2024 7 IENG 475: Computer-Controlled Manufacturing Systems

Friday 1:00 PM Lab 6 Bauman, Joshua Dahlstrom, George Dawley, Rosie Malsom, Spencer Swanson, Jordan Vilson, Marken 10/1/2024 8 IENG 475: Computer-Controlled Manufacturing Systems

Lab Schedule 1st Lab Today/Friday: Safety Theory Mfg Eng Lab Review Lab assignment from Schedule Page Meet in MFG ENG Lab (need to start labs on time) Take notes during lab in LAB Engineering Notebook (everyone) Lab assignments (1 per team) usually due next lab brief summary and documentation of design/exercise short answer to questions (if any) copy pages from everyone 5S at end of each lab Primary result of lab exercises is to complete project Open Lab times as necessary (e-mail for appointment) Open class and lab periods reserved at end of term (2 weeks) Use Finals Week for project documentation & demo 10/1/2024 9 IENG 475: Computer-Controlled Manufacturing Systems

Lab Capabilities / Project Reqs Five - Six processes (plus assembly) needed to produce project Laser Engraver CNC Mill CNC Lathe CNC Router(s) 3-D Printer(s) Drill Press (Single-cycle Automatic / Manual) 5 in 1 Machine (Table Saw / Sanding) Robot(s) / Machine Vision Stock Wood (Red Oak, Ash, MDF) Plastic (ABS, Acetal, Acrylic, PLA) Leather Tile Purchased Material Screws, Hinges, Magnets, Stock, Stain, Paint 10/1/2024 10 IENG 475: Computer-Controlled Manufacturing Systems

Laboratory Software SolidWorks This software will model the solids you need for project We need to follow certain lab conventions for production MasterCAM for Solidworks This software will help create process plans for project Speeds up the generation of CNC code, greatly! May load SolidWorks & MasterCAM for SolidWorks on yours See links on Materials page Takes about 1-1/2 hours best done from Lab jump drive during a lab Might only work from MFG ENG Lab Could try to VPN into SDSM&T Does work from Collaboration Space, Design Studio May load MakerBot software on any capable computer This software will let you orient and control the 3-D printers 10/1/2024 11 IENG 475: Computer-Controlled Manufacturing Systems

Project Concept 1 Expanding Cribbage Board Bottom, Slide Base & Slide: One color Material: Red Oak Design of slide must incorporate SMD moniker Design of slide base must incorporate individually customized text Design of slide base must incorporate CO2 laser engraving Design of bottom must contain card deck and pegs Bottom must have four button feet Stock: 5.45 x 5.45 x Slide Base & Bottom Stock: 5.45 x 5.45 x Slide Final dimensions depend on your fixture design(s) Pegs: Two colors Material: Red Oak/Ash; ABS, ACETAL or PLA plastic Each member designs their own sculpted posts Stock: dia x 3 long Final: 0.25 dia x 1.00 long (max, each post) 10/1/2024 12 IENG 475: Computer-Controlled Manufacturing Systems

Project Concept 1 Modular Pachisi Board four modules make a game set Slide Base & Slide(s): One color Material: Red Oak Design of slide top must incorporate SMD moniker & custom text Design of slide bottom must be of game board Design of slides must incorporate CO2 laser engraving Design of slide base must contain pawns & dice (dice are 3-D printed PLA) Slide Base bottom must have four button feet & connect to slide as the Start Stock: 5.45 x 5.45 x Slide Base Stock: 5.45 x 5.45 x or Slide (team choice!) Final dimensions depend on your fixture design(s) Pawns: One color Material: Red Oak Each member designs their own sculpted pawns Stock: dia x 4 long Final: 0.25 dia x long (max, each pawn) 10/1/2024 13 IENG 475: Computer-Controlled Manufacturing Systems

Project Concept 3 Chess Set Custom Case Top & Chess Board Base: Two parts must contain all chess pieces One color Material: Red Oak & Plastic/Metal Design of case top must incorporate SMD moniker Design of base bottom will be chess board Engraved Insert (plastic/metal) Design of chess board must incoporate CO2 laser engraving Stock: 5.45 x 5.45 x Case Top & Base Final dimensions depend on your fixture design(s) Chess Pieces: Two colors Material(s): Red Oak/Ash& Stain/Paint; ACETAL or PLA plastic Each member designs at least one piece, add group pawn design Stock: dia x 3 long Final: 0.25 dia x 1.00 long (max, piece), 1/2 long (max, pawn) 10/1/2024 14 IENG 475: Computer-Controlled Manufacturing Systems

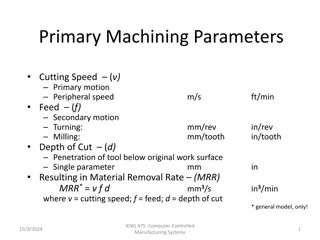

Manufacturing Operations What competitive trends exist? Where are products being made? What kind of products are being made at these locations? How are products being made at these locations? What is the basis for manufacturing competitiveness? Competitive Advantage(s): 10/1/2024 15 IENG 475: Computer-Controlled Manufacturing Systems

Levels of Automation Manual Production using single station manned cells operating independently 1. Automated Production using single station automated cells operating independently 2. Automated, Integrated Production using multi- station automated systems with automated material handling 3. The appropriate level of automation is situational there is no universal best answer! 10/1/2024 16 IENG 475: Computer-Controlled Manufacturing Systems

Manufacturing Operations Mfg Plant Limitations & Capabilities: Technological Processing Capabilities Physical Production Capabilities Production Capacity Limits Conditions for Appropriate Automation: Predictable, stable / expanding market Need to satisfy business objectives of firm Technology must be available at the right: Performance Cost Maturity 10/1/2024 17 IENG 475: Computer-Controlled Manufacturing Systems

Reasons for Automating To increase labor productivity To reduce labor cost To mitigate the effects of labor shortages To reduce or eliminate routine manual tasks To improve worker safety To accomplish processes that cannot be done manually To improve product quality To reduce manufacturing lead time To avoid the high cost of not automating when you could have! 10/1/2024 18 IENG 475: Computer-Controlled Manufacturing Systems

Reasons NOT to Automate Task is too technologically difficult to automate Product life cycle is too short Product is too customized Product demand is too variable To reduce the risk ($) of product failure To deal with these aspects, use the USA Principle: Understand Simplify Automate 10/1/2024 19 IENG 475: Computer-Controlled Manufacturing Systems