Caterpillar Cat D6T XW PAT TRACK-TYPE TRACTOR (Prefix WRN) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

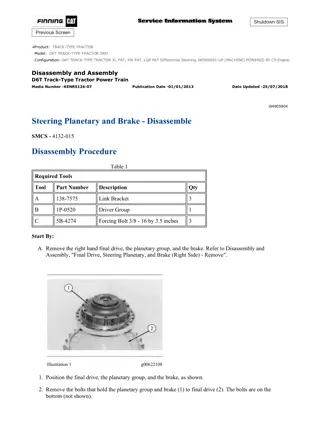

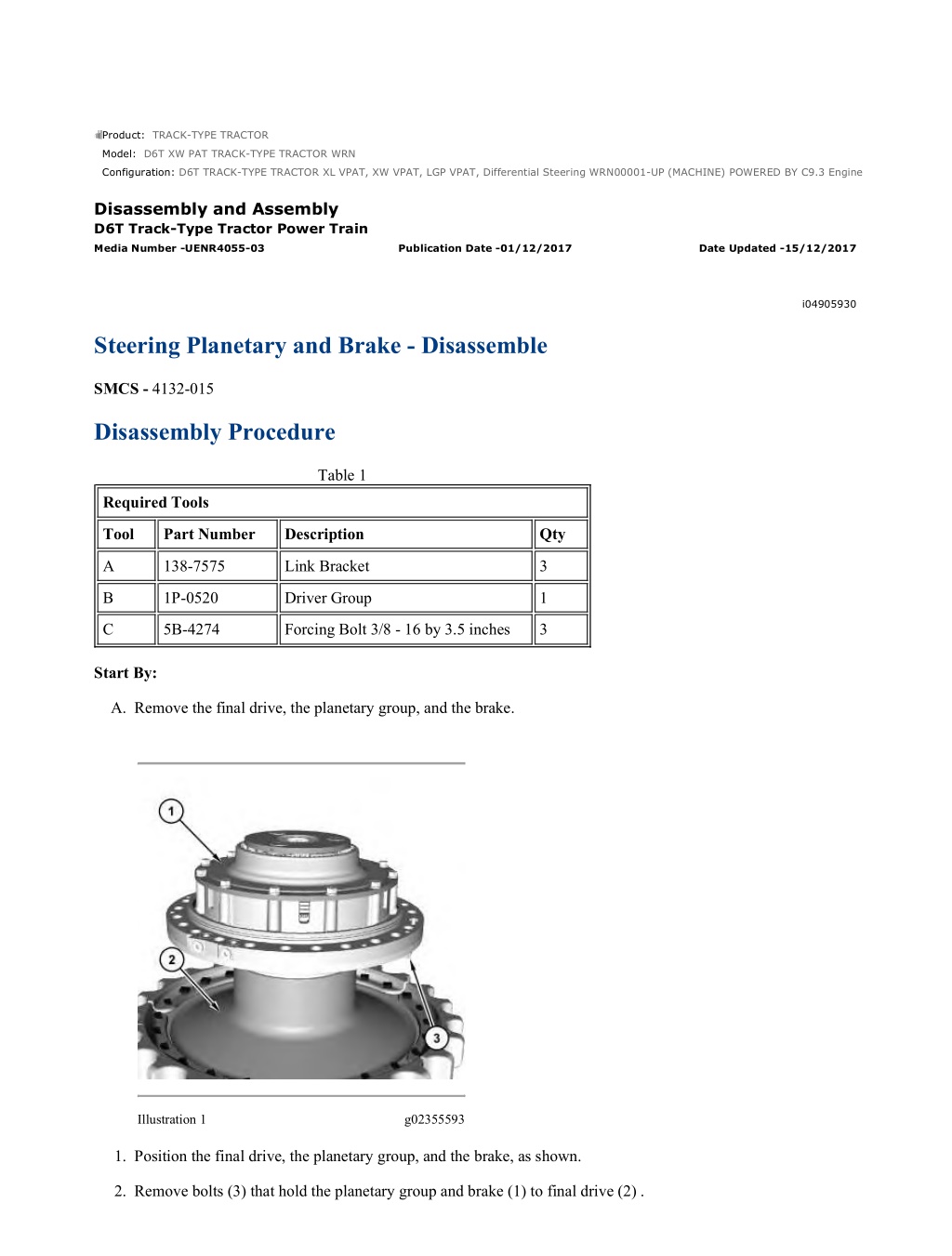

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 1/6 Product: TRACK-TYPE TRACTOR Model: D6T XW PAT TRACK-TYPE TRACTOR WRN Configuration: D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Steering WRN00001-UP (MACHINE) POWERED BY C9.3 Engine Disassembly and Assembly D6T Track-Type Tractor Power Train Media Number -UENR4055-03 Publication Date -01/12/2017 Date Updated -15/12/2017 i04905930 Steering Planetary and Brake - Disassemble SMCS - 4132-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Description Qty A 138-7575 Link Bracket 3 B 1P-0520 Driver Group 1 C 5B-4274 Forcing Bolt 3/8 - 16 by 3.5 inches 3 Start By: A. Remove the final drive, the planetary group, and the brake. Illustration 1 g02355593 1. Position the final drive, the planetary group, and the brake, as shown. 2. Remove bolts (3) that hold the planetary group and brake (1) to final drive (2) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 2/6 3. Attach Tooling (A) and a suitable lifting device to the planetary group and brake. 4. Install Tooling (C) in the final drive hub. 5. Tighten the forcing screws evenly in order to remove the planetary group and brake (1) from final drive (2) . The weight of planetary group and brake (1) is approximately 136 kg (300 lb). Illustration 2 g02355596 Personal injury can result from parts and/or covers under spring pressure. Spring force will be released when covers are removed. Be prepared to hold spring loaded covers as the bolts are loosened. 6. Remove bolts (4) . Remove ring gear (5) from housing (6) . Illustration 3 g02355619 7. Remove friction discs (7) and the brake plates from the housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 3/6 Illustration 4 g02355621 Illustration 5 g02355623 8. Remove bolts (8) and plate (9) . 9. Position the housing on suitable cribbing. Note: Do not allow planetary carrier (10) to fall when the carrier is pressed from housing (6) . Note: If a shim pack is present between the plate (9) and planetary carrier (10) . Reuse the same shim pack during assembly only if reusing the same planetary carrier (10) . If a new planetary carrier (10) is being used the shim pack should be discarded. 10. Use Tooling (B) and a suitable press to remove planetary carrier (10) from housing (6) . 11. Remove bearing cone (11) from the housing. Illustration 6 g01205303 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 4/6 12. Remove ring (14) from planetary carrier (10) . Remove bolts (13) . Remove slinger (12) from the planetary carrier. NOTICE The bearing is destroyed if the bearing is removed. 13. If necessary, remove bearing cone (15) from planetary carrier (10) . Illustration 7 g00622128 14. Use a hammer and a punch to push pin (17) in shaft (16) . Illustration 8 g01205304 15. Remove shaft (16) , planetary gear (19) , discs (20) , and bearings (21) from planetary carrier (10) . 16. Remove pin (17) from shaft (16) . 17. Repeat Steps 14 through 16 for the remaining planetary gears. 18. Remove sun gear (18) from planetary carrier (10) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 5/6 Illustration 9 g00622132 Personal injury can result from parts and/or covers under spring pressure. Spring force will be released when covers are removed. Be prepared to hold spring loaded covers as the bolts are loosened. 19. Remove bolts (22) and washers. 20. Remove retainer (23) from piston (24) . Illustration 10 g00622155 21. If necessary, remove bearing cups (25) and seal ring (26) from retainer (23) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 6/6 Illustration 11 g00622156 22. Remove piston (24) and O-ring seal (27) from the housing. Illustration 12 g00622157 23. Remove seal ring (28) from piston (24) . Note: Inspect the O-ring seals. If necessary, replace the O-ring seals. Illustration 13 g00819345 24. Remove spring (29) and ring (30) from housing (5) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

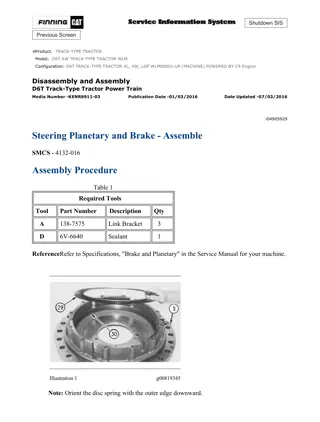

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 1/6 Product: TRACK-TYPE TRACTOR Model: D6T XW PAT TRACK-TYPE TRACTOR WRN Configuration: D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Steering WRN00001-UP (MACHINE) POWERED BY C9.3 Engine Disassembly and Assembly D6T Track-Type Tractor Power Train Media Number -UENR4055-03 Publication Date -01/12/2017 Date Updated -15/12/2017 i04905929 Steering Planetary and Brake - Assemble SMCS - 4132-016 Assembly Procedure Table 1 Required Tools Tool Part Number Description Qty A 138-7575 Link Bracket 3 D 6V-6640 Sealant 1 ReferenceRefer to Specifications, "Brake and Planetary" in the Service Manual for your machine. Illustration 1 g00819345 Note: Orient the disc spring with the outer edge downward. 1. Install ring (30) and spring (29) in housing (5) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 2/6 Illustration 2 g00622157 2. Apply clean oil to seal ring (28) . Note: Orient the seal ring with the lip downward. Refer to Illustration 2. 3. Install seal ring (28) in piston (24) . Illustration 3 g00622156 4. Install piston (24) and O-ring seal (27) in the housing. Illustration 4 g00622155 5. Lower the temperature of bearing cups (25). Install bearing cups (25) in retainer (23) . Note: Orient the seal ring with the lip downward. Refer to Illustration 4. 6. Apply clean oil to seal ring (26). Install seal ring (26) in retainer (23) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 3/6 Illustration 5 g00622132 Improper assembly of parts that are spring loaded can cause bodily injury. To prevent possible injury, follow the established assembly procedure and wear protective equipment. 7. Install retainer (23) on piston (24). Align the oil passage in retainer (23) with the oil passage and the O-ring seal in the housing. Install bolts (22) . Illustration 6 g01205304 8. Install sun gear (18) in planetary carrier (10) . 9. Install bearings (21) in planetary gear (19) . 10. Install discs (20) and planetary gear (19) in planetary carrier (10). Install shaft (16) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 4/6 Illustration 7 g00622128 Note: If the rubber in pin (17) is damaged, replace pin (17) . 11. Align the hole in shaft (16) with the hole in planetary carrier (10) and install pin (17). Install pin (17) until the pin is even with the surface of planetary carrier (10) . 12. Repeat Steps 9 through 11 for the remaining planetary gears. Illustration 8 g01205303 Note: If bearing cone (15) was removed from planetary carrier (10), a new bearing must be installed. 13. Raise the temperature of bearing cone (15). Install the bearing cone on planetary carrier (10) . 14. Apply Tooling (D) to the flange of slinger (12) . 15. Install slinger (12) on planetary carrier (10). Install bolts (13). Tighten the bolts to a torque of 50 10 N m (37 7 lb ft). 16. Install ring (14) in planetary carrier (10) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 5/6 Illustration 9 g02356056 17. Position housing (6) on planetary carrier (10) . 18. Raise the temperature of bearing cone (11). Install bearing cone (11) on planetary carrier (10) . Illustration 10 g02355621 19. Position plate (9) onto the planetary carrier (10) . Note: Install shim pack between plate (9) and planetary carrier (10), only if there was a shim pack originally installed in the differential group and if the same planetary carrier is being reused. Shim pack thickness should be 0.31 mm (0.0122inch). 20. Install bolts (8) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 6/6 Illustration 11 g02355619 21. Install friction discs (7) and brake plates. Alternate the friction discs and the brake plates. Illustration 12 g02355596 22. Position ring gear (5) on housing (6) . 23. Install bolts (4). Tighten bolts (4) to a torque of 135 20 N m (100 15 lb ft). Illustration 13 g02355593 24. Use a suitable lifting device and Tooling (A) in order to position the planetary group and brake (1) on final drive (2). The weight of the planetary group and brake is approximately 135 kg (300 lb). 25. Install the bolts (3) . End By: Install the final drive, the planetary group, and the brake. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

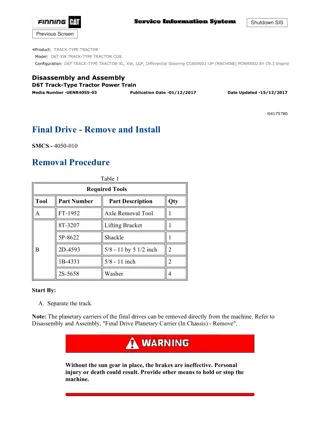

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 1/4 Product: TRACK-TYPE TRACTOR Model: D6T XW PAT TRACK-TYPE TRACTOR WRN Configuration: D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Steering WRN00001-UP (MACHINE) POWERED BY C9.3 Engine Disassembly and Assembly D6T Track-Type Tractor Power Train Media Number -UENR4055-03 Publication Date -01/12/2017 Date Updated -15/12/2017 i04175780 Final Drive - Remove and Install SMCS - 4050-010 Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A FT-1952 Axle Removal Tool 1 8T-3207 Lifting Bracket 1 5P-8622 Shackle 1 B 2D-4593 5/8 - 11 by 5 1/2 inch 2 1B-4331 5/8 - 11 inch 2 2S-5658 Washer 4 Start By: A. Separate the track. Note: The planetary carriers of the final drives can be removed directly from the machine. Refer to Disassembly and Assembly, "Final Drive Planetary Carrier (In Chassis) - Remove". Without the sun gear in place, the brakes are ineffective. Personal injury or death could result. Provide other means to hold or stop the machine. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 2/4 Illustration 1 g00865052 1. Remove bolts (2) and cover (3) from final drive (1) . Illustration 2 g00865024 2. Use Tooling (A) in order to remove axle (4) . Illustration 3 g00865075 3. Remove two bolts (5) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 3/4 Illustration 4 g00826743 4. Adjust the top bracket of Tooling (B) until Dimension (X) is 222.25 mm (8.750 inch). Illustration 5 g00865077 5. Remove two bolts (6) and the nuts from the sprocket segment. Discard bolts (6) and the nuts. Illustration 6 g02356097 6. Fasten Tooling (B) and a suitable lifting device to the final drive. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 4/4 Illustration 7 g00865094 7. Remove bolts (7) that hold the final drive and the brake together. Illustration 8 g00865095 8. Use Tooling (B) to remove final drive (1) from the machine. The weight of final drive (1) is approximately 454 kg (1000 lb). Installation Procedure 1. Install final drive (1) in the reverse order of removal. a. Tighten bolts (7) to a torque of 700 90 N m (516 66 lb ft). b. Lubricate new bolts (6) with SAE 30 oil. Install new bolts (6) and the nuts. Tighten bolts (6) to a torque of 175 40 N m (130 30 lb ft). Tighten bolts (6) an additional 1/3 turn. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

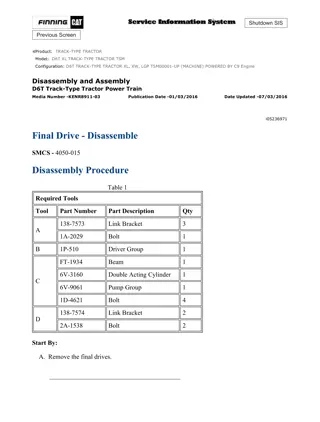

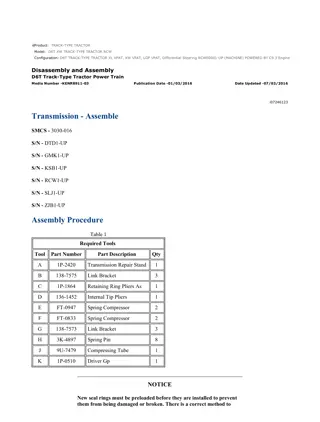

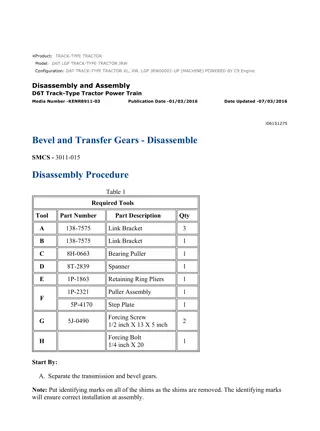

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 1/5 Product: TRACK-TYPE TRACTOR Model: D6T XW PAT TRACK-TYPE TRACTOR WRN Configuration: D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Steering WRN00001-UP (MACHINE) POWERED BY C9.3 Engine Disassembly and Assembly D6T Track-Type Tractor Power Train Media Number -UENR4055-03 Publication Date -01/12/2017 Date Updated -15/12/2017 i05236971 Final Drive - Disassemble SMCS - 4050-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty 138-7573 Link Bracket 3 A 1A-2029 Bolt 1 B 1P-510 Driver Group 1 FT-1934 Beam 1 6V-3160 Double Acting Cylinder 1 C 6V-9061 Pump Group 1 1D-4621 Bolt 4 138-7574 Link Bracket 2 D 2A-1538 Bolt 2 Start By: A. Remove the final drives. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 2/5 Illustration 1 g01195912 1. Install Tooling (A) and a suitable lifting device to planetary carrier (3) . 2. Remove bolts (1). Remove planetary carrier (3) and the two O-ring seals from the hub. The weight of planetary carrier (3) is approximately 137 kg (302 lb). 3. Remove retainers (2) . Illustration 2 g00841089 4. Place support under planetary carrier (3) in order to prevent damage. Use Tooling (B) and a suitable press to remove the planetary gear shafts. 5. Remove planetary gears (4) from planetary carrier (3) . Illustration 3 g00841091 6. Remove bearing cones (5) from gears (4) . 7. Remove the bearing cups from each side of the gears. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 3/5 Illustration 4 g00841092 Illustration 5 g01195913 8. Remove bolts (6) and retainer (7) . 9. Attach a suitable lifting device to hub (12) and ring gear (8). The weight of hub (12) and ring gear (8) is approximately 68 kg (150 lb). Remove hub (12) and ring gear (8) . Illustration 6 g01195915 10. Turn over hub (9) and ring gear (8). Remove retaining ring (10). Attach a suitable lifting device to hub (9). The weight of hub (9) is approximately 37 kg (82 lb). The weight of ring gear (8) is approximately 32 kg (71 lb). Remove hub (9) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 4/5 Illustration 7 g00841095 11. Install Tooling (C) on hub (12). Note: Do not lift hub (12) too high. Do not allow hub (12) to contact the fitting on the hydraulic cylinder. 12. Use Tooling (C) to loosen hub (12) from spindle (13). Remove Tooling (C) . 13. Remove bearing cone (11) . Illustration 8 g01195917 14. Install Tooling (D) and a suitable lifting device to hub (12). Remove hub (12) from spindle (13). The weight of hub (12) is approximately 180 kg (397 lb). Illustration 9 g00841099 15. Turn over hub (12). Remove Duo-Cone seal kit (15). Use a hammer and a punch to remove bearing cup (16) . 16. Turn over the hub. Remove bearing cup (14) from the hub. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 5/5 Note: If the Duo-Cone seal will be reused, mark the seal kits for installation purposes. Illustration 10 g00841101 Note: Bearing cone (18) may be damaged if the bearing cone is removed from spindle (13) . 17. Remove Duo-Cone seal (19) from spindle (13) . 18. If necessary, remove bearing cone (18) from the spindle. 19. Remove lip seal (17) from spindle (13) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

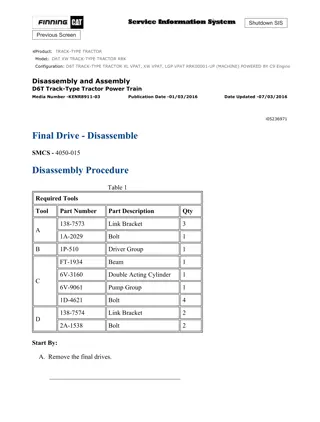

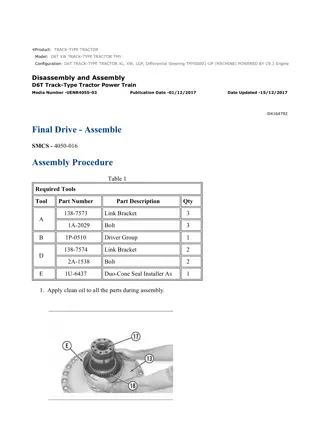

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 1/5 Product: TRACK-TYPE TRACTOR Model: D6T XW PAT TRACK-TYPE TRACTOR WRN Configuration: D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Steering WRN00001-UP (MACHINE) POWERED BY C9.3 Engine Disassembly and Assembly D6T Track-Type Tractor Power Train Media Number -UENR4055-03 Publication Date -01/12/2017 Date Updated -15/12/2017 i04164792 Final Drive - Assemble SMCS - 4050-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty 138-7573 Link Bracket 3 A 1A-2029 Bolt 3 B 1P-0510 Driver Group 1 138-7574 Link Bracket 2 D 2A-1538 Bolt 2 E 1U-6437 Duo-Cone Seal Installer As 1 1. Apply clean oil to all the parts during assembly. Illustration 1 g00841209 2. Use Tooling (B) to install lip seal (17) in spindle (13) to a minimum depth of 9.65 mm (0.4 inch). Do not apply excessive force to lip seal (17) during installation in order to avoid damaging the seal. Put clean oil on the lip of the seal. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 2/5 3. Raise the temperature of bearing cone (18) to a maximum temperature of 135 C (275 F). Install bearing cone (18) on spindle (13) . Note: Before the installation of the Duo-Cone seal, refer to Disassembly and Assembly, "Duo-Cone Conventional Seals - Install" for the correct procedure. 4. Use Tooling (E) to install the Duo-Cone seal on spindle (13) . Illustration 2 g00841210 5. Lower the temperature of bearing cups (14) and (16). Install bearing cups (14) and (16) in hub (12) . 6. Use Tooling (E) to install the Duo-Cone seal in hub (12) . Illustration 3 g01195917 7. Install Tooling (D) on hub (12). Attach a suitable lifting device to Tooling (D). Carefully position hub (12) on spindle (13) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 3/5 Illustration 4 g00841212 8. Raise the temperature of bearing cone (11). Install bearing cone (11) on spindle (13). Illustration 5 g01195915 9. Attach a suitable lifting device to hub (9) and position hub (9) in ring gear (8). Install retaining ring (10) . Illustration 6 g01195913 10. Turn over the hub (9) and ring gear (8). Attach a suitable lifting device to hub (9) and the ring gear (8) into position in hub (12). Illustration 7 g00841092 11. Put retainer (7) into position. Install bolts (6) while the hub is slowly rotated. Tighten bolts (6) evenly to a torque of 135 15 N m (100 11 lb ft). The retainer must contact the end of spindle (13) after bolts (6) have been tightened. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 4/5 Illustration 8 g00841213 12. Lower the temperature of bearing cups (20) and (21). Install the bearing cups in three planetary gears (4) . Illustration 9 g00841215 Illustration 10 g00841216 13. Position the planetary carrier in a press. The shaft (22) must be in position with proper support in order to be a positive stop for the shaft. NOTICE https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 5/5 The shaft must be correctly installed. If the shaft is incorrectly installed, the bearing preload will be incorrect. This will result in component damage. 14. Position planetary gear (4) in the planetary carrier. 15. Lower the temperature of shaft (22). Use a suitable press to install the shaft in the planetary carrier. After the installation, the end of shaft (22) must be flush with the retainer of the planetary carrier. This will provide the correct bearing preload. The gear must rotate by hand after installation. If the gear does not rotate, the problem must be corrected. Repeat this procedure for all three shafts. Illustration 11 g01195912 16. Install three retainers (2) on shafts (22) . 17. Install Tooling (A). Attach a suitable lifting device to Tooling (A). Install the two O-ring seals on the planetary carrier. Align the drain hole in the planetary carrier with the drain hole in the hub. 18. Position the planetary carrier in the hub. 19. Install bolts (1) that hold planetary carrier (3) to the hub. Remove Tooling (A) . End By: Install the final drives. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

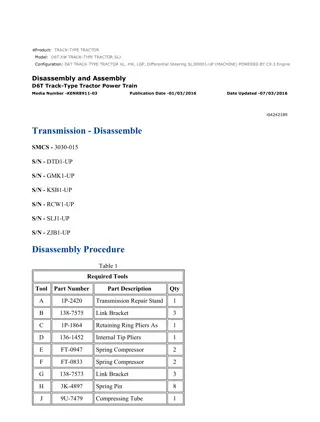

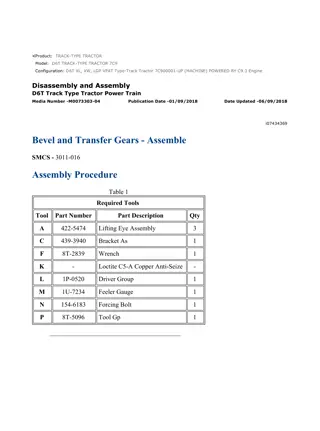

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 1/6 Product: TRACK-TYPE TRACTOR Model: D6T XW PAT TRACK-TYPE TRACTOR WRN Configuration: D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Steering WRN00001-UP (MACHINE) POWERED BY C9.3 Engine Disassembly and Assembly D6T Track-Type Tractor Power Train Media Number -UENR4055-03 Publication Date -01/12/2017 Date Updated -15/12/2017 i06852073 Final Drive, Steering Differential, and Brake (Left Side) - Remove and Install SMCS - 4050-010-LT; 4132-010-LT Removal Procedure Table 1 Required Tools Tool Part Number Description Qty FT-1952 Axle Removal Tool 1 A 1U-7432 Adapter Assembly 1 8T-3207 Lifting Bracket 1 5P-8622 Shackle 1 B 1D-4615 Bolt 2 1B-4331 Nut 2 5P-8248 Washer 4 1B-4331 Nut 1 5P-8248 Washer 2 439-3939 Link Bracket 1 439-3940 Link Bracket 1 C 8S-9906 Ratchet Puller 1 1A-1460 Bolt 1 5P-8245 Washer 1 1A-8063 Bolt 1 D 5B-4274 Bolt 3 Start By: a. Separate the track. b. Remove the drive axles. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 2/6 c. Remove the steering motor. d. Drain the oil from the final drive. Refer to Operation and Maintenance Manual, "Final Drive Oil - Change". Illustration 1 g01127146 1. Remove bolts (1) from adapter (2). 2. Install Tooling (D) in Holes (X). Remove adapter (2). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

D6T TRACK-TYPE TRACTOR XL VPAT, XW VPAT, LGP VPAT, Differential Ste... 3/6 Illustration 2 g01127151 3. Remove O-ring seal (3) from adapter (2). Illustration 3 g01127160 Illustration 4 g01127169 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/8

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com