Caterpillar Cat D6T TRACK-TYPE TRACTOR (Prefix NDY) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Service Repair Manual Models D6T TRACK-TYPE TRACTOR

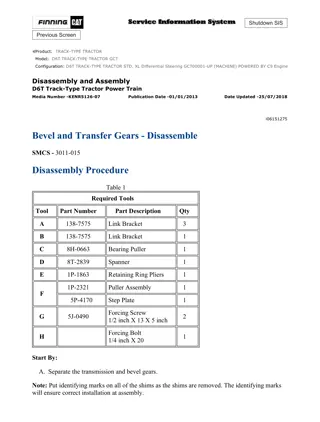

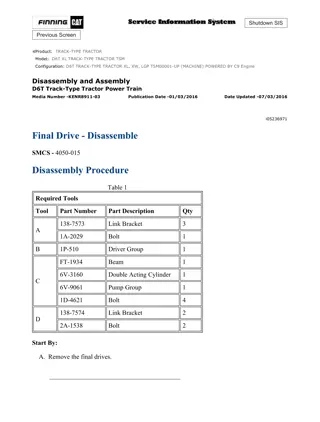

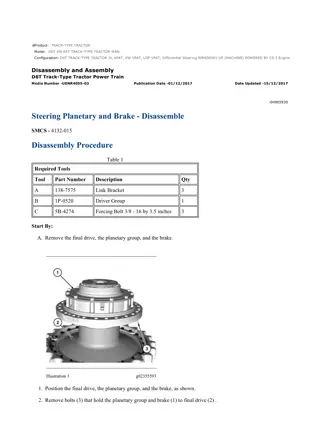

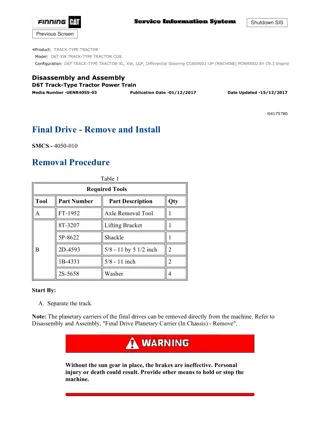

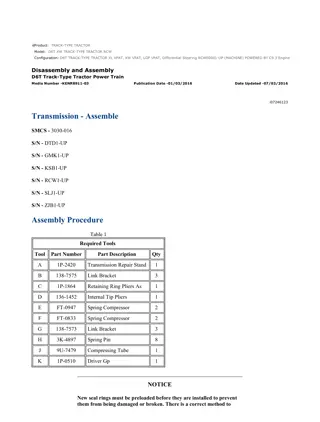

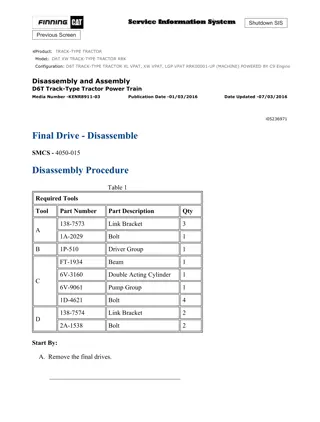

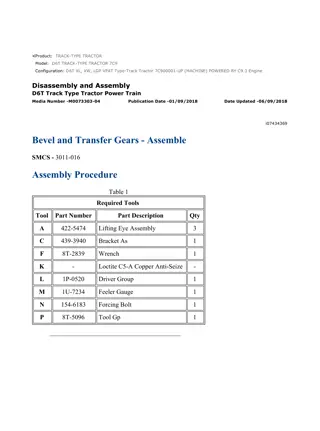

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 1/30 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D6T TRACK-TYPE TRACTOR NDY Configuration: D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED BY C9.3 Engine Disassembly and Assembly D6T Track Type Tractor Power Train Media Number -M0073303-04 Publication Date -01/09/2018 Date Updated -06/09/2018 i06746339 Transmission - Disassemble SMCS - 3030-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-2420 Transmission Repair Stand 1 B 136-1452 Retaining Ring Pliers As 1 C 421-5663 Lifting Eye Assembly 3 D 477-3190 Eyebolt Assembly 3 E 316-0706 Pliers - Locking 1 F 156-7100 Slide Hammer Puller Gp 1 G 421-5662 Lifting Eye Assembly 3 For access to a video of this procedure, scan the QR code below with a QR enabled device, or copy the link below. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 2/30 Illustration 1 g06247857 Table 2 Caterpillar Channel1 Media Number: CATU1334 Title: D6T Transmission Disassembly Channel1 URL: https://channel1.mediaspace.kaltura.com/media/D6T+Transmission+Repair/1_h6okgcnr Start By: a. Separate the transmission and bevel gears. Note: The transmission modulating valves must be recalibrated if any of the following procedures are performed: The transmission modulating valve and/or the solenoid is replaced. The transmission is serviced or the transmission is replaced. The electronic control module is replaced. Reference: Refer to Testing and Adjusting, "Transmission Clutch Pressure - Test". Note: The friction discs and the clutch plates from the individual clutches must be kept in the correct order. The friction discs and the clutch plates must be kept with the original clutch housings. The different clutches use different friction material. Do not mix the clutch plates and friction plates. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 3/30 Illustration 2 g06334890 Note: The weight of the transmission is approximately 458 kg (1010 lb). Mark the housings for alignment during the assembly procedure. 1. Remove O-ring seals (1) and (4) from the transmission cover. 2. Remove bolts (3) (not shown), and the strips (not shown). 3. Remove tubes (2) and the O-ring seals. 4. Remove fittings (5) and the O-ring seals. Remove locknut (6). Position the receptacle assembly into the case. Illustration 3 g06326832 5. Completely disconnect harness assembly (7) from all locations. 6. Remove bolts (8) and sensor (9). 7. Remove bolts (10) (not shown) and sensor (11). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 4/30 Illustration 4 g06101945 8. Remove O-ring seal (12) from sensor (9). Repeat for the other sensor. Illustration 5 g06334892 9. Remove bolts (13) and harness assembly (7). 10. Remove valve assemblies (14). Illustration 6 g06326123 11. Remove fitting (15), bolts (16), and solenoid valve (17) from valve assembly (14). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 5/30 Illustration 7 g06326138 12. Remove O-ring seals (18) from solenoid valve (17). 13. Repeat Steps 11 and 12 for the remaining valve assemblies (14). Illustration 8 g06326153 14. Remove valve assemblies (19) and the orifice plates. Illustration 9 g06326149 15. Remove fitting (20), nut (21), and coil assembly (22) from valve assembly (19). Repeat for the remaining valve assembly (19). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 6/30 Illustration 10 g06326224 16. Remove bolts (23) and valve assembly (24). Illustration 11 g06334897 Personal injury can result from parts and/or covers under spring pressure. Spring force will be released when covers are removed. Be prepared to hold spring loaded covers as the bolts are loosened. 17. Use a suitable prybar to raise hub clutch (28). Remove retaining ring (25). 18. Remove four bolts (29). 19. Remove bolts (26) and (30) in an alternating pattern until the spring force is relieved. 20. Remove manifold (27). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 7/30 Illustration 12 g06326230 21. Remove the retaining ring and bearing (31). Illustration 13 g06334986 22. Remove dowels (35), springs (33), and rods (34) (not shown). 23. Remove friction disc (32), clutch plate (36), and friction disc (37) (not shown). Illustration 14 g06334988 24. Remove seal rings (40) and O-ring seal (39). 25. Use Tooling (B) and two people to compress retaining ring (38). With retaining ring (38) compressed remove rotating housing (41) and retaining ring (38). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 8/30 Illustration 15 g06334989 Do not remove the retaining ring until the spring force has been released. Failure to do so could result in personal injury or death. In order to prevent this, use a suitable press to hold the spring force while the retaining ring is removed. Slowly release the spring tension with the press after the retaining ring has been removed. Note: Be sure not to overcompress bevel springs (44). Ensure that adequate space is between the tooling and retaining ring (41). 26. Position rotating housing (41) into a suitable press. 27. Use suitable tooling to apply pressure to ring (42). 28. Depress bevel springs (44) enough to remove retaining ring (43). 29. Remove ring (42). Illustration 16 g06326252 30. Remove springs (44) and note the orientation of springs (44) for assembly purposes. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 9/30 Illustration 17 g06326253 31. Remove piston (45) from rotating housing (41). Illustration 18 g06326254 32. Remove seal rings (46). Illustration 19 g06326256 33. Remove retaining ring (49). 34. Remove hub clutch (47), clutch discs (48), and the plates. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 10/30 Illustration 20 g06326259 35. Remove retaining ring (50) and hub clutch (51). Illustration 21 g06334991 Note: Rotate output shaft (54) as needed to gain access to all bolts (53). 36. Remove retaining rings (52) and bolts (53). Illustration 22 g06326263 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 11/30 Personal injury can result from parts and/or covers under spring pressure. Spring force will be released when covers are removed. Be prepared to hold spring loaded covers as the bolts are loosened. 37. Remove piston (59). 38. Remove nine bolts (55). 39. Equally loosen bolts (56) and (57) in an alternating pattern until the spring force is relieved. 40. Use two people to remove clutch housing (58). The weight of clutch housing (58) is approximately 35 kg (77 lb). Illustration 23 g06334994 41. Remove seal rings (60) from piston (59). Illustration 24 g06326267 42. Remove retaining ring (61) and hub assembly (62) from clutch housing (58). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 12/30 Illustration 25 g06326274 43. Remove seal rings (64) and bearing (63). Illustration 26 g06326486 44. Remove O-ring seal (65). Illustration 27 g06326493 45. Remove springs (66), rods (67) (not shown), and dowels (68). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 13/30 Illustration 28 g06326499 46. Remove ring gear (69). 47. Remove clutch discs (70) and plate (71). Illustration 29 g06326501 NOTICE To avoid damage, use two bolts (55) as guides. Do not engage the threads. 48. Attach Tooling (C) and a suitable lifting device to clutch housing (72). The weight of clutch housing (72) is approximately 60 kg (132 lb). 49. Remove clutch housing (72). 50. Position clutch housing (72) on suitable cribbing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 14/30 Illustration 30 g06335003 Personal injury can result from parts and/or covers under spring pressure. Spring force will be released when covers are removed. Be prepared to hold spring loaded covers as the bolts are loosened. 51. Remove piston (73). 52. Remove retaining rings (75), retainers (74), the springs, and the poppets. 53. Remove plug (76) and the O-ring seal. Illustration 31 g06326506 54. Remove seals (77) from piston (73). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 15/30 Illustration 32 g06326508 55. Attach Tooling (D) and a suitable lifting device to clutch hub (79). The weight of clutch hub (79) is approximately 45 kg (100 lb). 56. Use Tooling (E) and suitable cribbing to compress retaining ring (78) (not shown), and remove clutch hub (79). 57. Remove retaining ring (78) (not shown). Illustration 33 g06326512 58. Position shaft assembly (81) onto suitable cribbing. 59. Remove retaining ring (80) and sun gear (82). Note: Note the orientation of shafts (83) for assembly purposes. 60. Use tooling (F) to remove shafts (83) 61. Remove thrust discs (84), gears (85), and the bearings. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 16/30 Illustration 34 g06326525 62. Remove clutch hub (79). 63. Reposition shaft assembly (81) by 180 degrees. Illustration 35 g06326542 64. Remove retaining ring (87). 65. Remove ring gear (86) and the O-ring seal. Illustration 36 g06326544 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 17/30 Illustration 37 g06326548 Illustration 38 g06326556 66. Position shaft assembly (81) as shown in Illustration 36. 67. Position retaining ring (88) to Location (X) as shown in Illustration 37. 68. Use a suitable mallet to position gear (90) to Location (X) as show in Illustration 38. 69. Remove retaining ring (89). 70. Remove gear (90) and the bearing. Illustration 39 g06326565 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 18/30 71. Remove ring (91) and remove retaining ring (88) (not shown). 72. Remove bushings (92). Illustration 40 g06327787 73. Position clutch hub (79) by 180 as shown in Illustration 40. 74. Remove retaining ring (93) and reaction plate (94). Illustration 41 g06326575 75. Remove retaining ring (95). 76. Remove clutch discs (96) and plates (97) from clutch hub (79). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 19/30 Illustration 42 g06335009 77. Position clutch hub (79), as shown in Illustration 42, and remove three bolts (98). 78. Remove planetary carrier assembly (99) and the O-ring seals at location (Y) as shown in Illustration 42. Illustration 43 g06326589 Typical Example Do not remove the retaining ring until the spring force has been released. Failure to do so could result in personal injury or death. In order to prevent this, use a suitable press to hold the spring force while the retaining ring is removed. Slowly release the spring tension with the press after the retaining ring has been removed. Note: Be sure not to overcompress bevel springs (103). Ensure that adequate space is between the tooling and retaining ring (102). 79. Position gear ring (100) into a suitable press. Use suitable tooling to apply pressure to ring (101). 80. Depress bevel springs (103) enough to remove retaining ring (102). 81. Remove retaining ring (102). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 20/30 Illustration 44 g06326593 Typical Example 82. Remove bevel springs (103) and note the orientation of bevel springs (103) for assembly purposes. Illustration 45 g06326606 Typical Example 83. Remove piston (104) from gear ring (100). Illustration 46 g06326611 Typical Example 84. Remove seals (105). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 21/30 Illustration 47 g06326619 85. Remove carrier assembly (107) and ring gear (106). Illustration 48 g06326625 86. Remove retaining ring (108) (not shown), gear (109), and the bearing. 87. Remove carrier assembly (110). 88. Remove the bearings from output shaft (54). Illustration 49 g06326655 89. Drive spring pin (111) into shaft (112) and remove shaft (112). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 22/30 90. Remove gear (113), thrust washers (114) (not shown), and the bearing. Illustration 50 g06326658 91. Use a suitable punch to remove spring pin (111) (not shown) from shaft (112). 92. Repeat steps 89 and 91 for the remaining shafts. Illustration 51 g06326668 93. Remove retaining ring (115). 94. Remove three bolts (116) and sensor rotor (117). Illustration 52 g06326684 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 23/30 Personal injury can result from parts and/or covers under spring pressure. Spring force will be released when covers are removed. Be prepared to hold spring loaded covers as the bolts are loosened. 95. Remove bolts (122) and (119). 96. Equally loosen bolts (118) and (120) in an alternating pattern until the spring force is relieved. 97. Remove clutch housing (121). 98. Position clutch housing (121) on the other side to gain access to the piston. 99. Remove the piston from clutch housing (121). 100. Remove the seals from the piston. Illustration 53 g06326713 101. Remove clutch plate (123), dowels (124), springs (125), and rods (126) (not shown). Illustration 54 g06326733 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 24/30 102. Remove clutch discs (127) and plates (129). 103. Use two people to remove carrier assembly (128). The weight of carrier assembly (128) is approximately 30 kg (66 lb). Illustration 55 g06326735 104. Remove retaining ring (132). 105. Remove ring gear (133) and seal (134). Illustration 56 g06326737 106. Remove gear (137) and gear assembly (136). 107. Remove O-ring seal (135) (not shown). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 25/30 Illustration 57 g06326741 108. Remove retaining ring (138) and bearing (139). Illustration 58 g06335018 Illustration 59 g06335016 109. Drive spring pin (140) into shaft (143) and remove shaft (143). 110. Remove gears (142), thrust washers (141), and bearings (144). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 26/30 Illustration 60 g06326745 111. Use a suitable punch to remove spring pin (140) (not shown ) from shaft (143). 112. Repeat Steps 109 and 111 for remaining the shafts. Illustration 61 g06326756 113. Remove bolts (145) and center plate (146). Illustration 62 g06326760 114. Remove friction discs (147) and clutch plates (148). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 27/30 Illustration 63 g06326764 115. Remove carrier assembly (149). Illustration 64 g06326768 116. Remove seal (150). Illustration 65 g06326771 117. Remove retaining ring (151) and remove bearing (152). 118. Compress retaining ring (153) and remove gear (154). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 28/30 Illustration 66 g06326774 Illustration 67 g06326780 119. Drive spring pin (155) into shaft (157) and remove shaft (157). 120. Remove gear (158), washers (156), and bearing (159). Illustration 68 g06326784 121. Use a suitable punch to remove spring pin (155) (not shown) from shaft (157). 122. Repeat steps 119 through 121 for remaining shafts (157). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 29/30 Illustration 69 g06326797 123. Remove seal (160). 124. Attach tooling (G) and a suitable lifting device to clutch housing assembly (161). The weight of clutch housing assembly (161) is approximately 51 kg (112 lb). 125. Remove clutch housing assembly (161). Illustration 70 g06326798 126. Position clutch housing assembly (161) to gain access to retaining ring (162). 127. Remove retaining ring (162). 128. Remove shaft assembly (163). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED ... 30/30 Illustration 71 g06326801 129. Remove O-ring seals (164) and seal (165). Illustration 72 g06326803 130. Remove retaining ring (166) and bearing (167). Illustration 73 g06326807 131. Position clutch housing assembly (161) as shown in Illustration 73and remove piston (168). 132. Remove the seals from piston (168). Copyright 1993 - 2021 Caterpillar Inc. Wed May 12 08:29:53 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

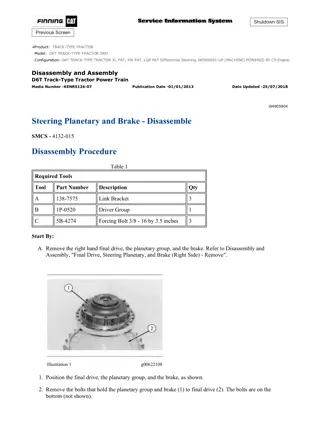

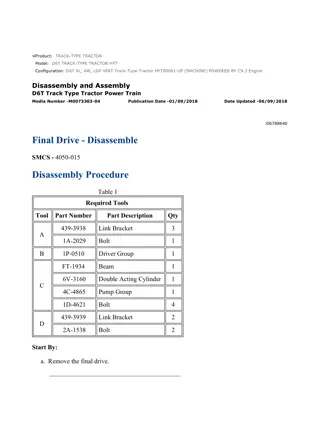

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 1/28 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D6T TRACK-TYPE TRACTOR NDY Configuration: D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED BY C9.3 Engine Disassembly and Assembly D6T Track Type Tractor Power Train Media Number -M0073303-04 Publication Date -01/09/2018 Date Updated -06/09/2018 i06746625 Transmission - Assemble SMCS - 3030-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-2420 Transmission Repair Stand 1 B 136-1452 Retaining Ring Pliers As 1 C 421-5663 Lifting Eye Assembly 3 D 477-3190 Eyebolt Assembly 3 E 316-0706 Pliers 1 G 421-5662 Lifting Eye Assembly 3 For access to a video of this procedure, scan the QR code below with a QR enabled device, or copy the link below. Illustration 1 g06247888 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 2/28 Table 2 Caterpillar Channel1 Media Number: CATU1452 Title: D6T Transmission Assembly Channel1 URL: https://channel1.mediaspace.kaltura.com/media/D6T+Transmission+Assembly/0_uu4hp2vz NOTICE New seal rings must be preloaded before they are installed to prevent them from being damaged or broken. There is a correct method to preload new seal rings prior to installation. Place your hands on each end of the seal ring, and pull (wind) the ends several inches past each other or until they almost make contact. Use care to keep the ring shaped like a circle. This will make an even bend (or ring "set") all around the ring. When the seal ring is in the groove of the hub, the ends must butt together lightly. Do not bend the seal ring. This does not make an even bend all the way around the ring. Do not attempt to use this method to preload a used seal ring. Also, do not use this procedure for cast iron seal rings. This will cause used or cast iron seal rings to break. Note: The friction discs and the clutch plates from the individual clutches must be kept in the correct order. The friction discs and the clutch plates must be kept with the original clutch housings. The different clutches use different friction material. The friction discs and the clutch plates cannot be swapped. Note: Lubricate the seals with the lubricant that is being sealed prior to installation. Illustration 2 g06326807 1. Install the seals onto piston (168). 2. Install piston (168) into clutch housing (161). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 3/28 Illustration 3 g06326803 3. Install bearing (167) and retaining ring (166). Illustration 4 g06326801 4. Install seal (165) and O-ring seals (164). Illustration 5 g06326798 5. Install shaft assembly (163). 6. Reposition clutch housing assembly (161) and install retaining ring (162). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 4/28 Illustration 6 g06326797 7. Attach tooling (F) and a suitable lifting device to clutch housing assembly (161). The weight of clutch housing assembly (61) is approximately 51 kg (112 lb). 8. Install clutch housing assembly (161). 9. Install seal (160). Illustration 7 g06326780 Illustration 8 g06326774 10. Install bearing (159) into gear (158). 11. Install washers (156) and gear (158). 12. Install shaft (157) and spring pin (155). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 5/28 13. Repeat Step 10 through 12 for remaining shafts (157). Illustration 9 g06326771 14. Install gear (154) and retaining ring (153). 15. Install bearing (152) and retaining ring (151). Illustration 10 g06326768 16. Install seal (150). Illustration 11 g06326764 17. Install carrier assembly (149). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 6/28 Illustration 12 g06326760 18. Install clutch plates (148) and friction discs (147). Illustration 13 g06326756 19. Install center plate (146) and bolts (145). Illustration 14 g06335016 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 7/28 Illustration 15 g06335018 20. Install bearings (144) into gears (142). 21. Install washers (141) and gears (142). 22. Install shaft (143) and spring pin (140). 23. Repeat Step 20 through 22 for the remaining shafts. Illustration 16 g06326741 24. Install bearing (139) and retaining ring (138). Illustration 17 g06326737 25. Install O-ring seal (135) (not shown). Install gear assembly (136) and gear (137). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

D6T XL, XW, LGP Track-Type Tractor NDY00001-UP (MACHINE) POWERED B... 8/28 Illustration 18 g06326735 26. Install seal (134) and ring gear (133). 27. Install retaining ring (132). Illustration 19 g06326733 28. Use two people to install carrier assembly (128). Weight of carrier assembly (128) is approximately 30 kg (66 lb). 29. Install plates (129) and clutch discs (127). Illustration 20 g06326713 30. Install rods (126) (not shown), springs (125), dowels (124), and clutch plate (123). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/5/12

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com