Caterpillar Cat 972M Wheel Loader (Prefix L8E) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

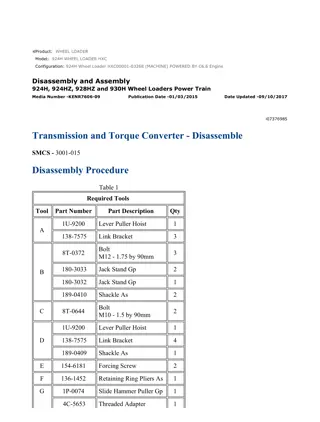

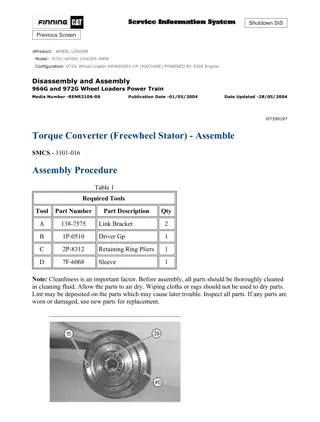

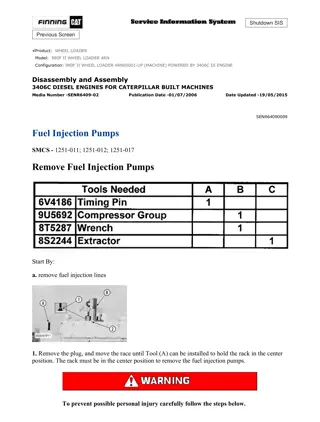

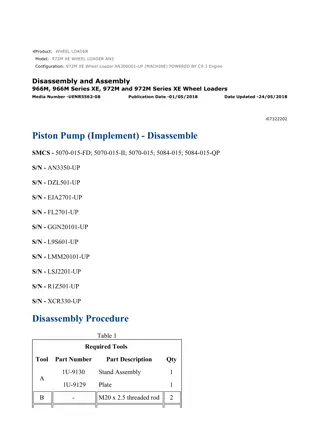

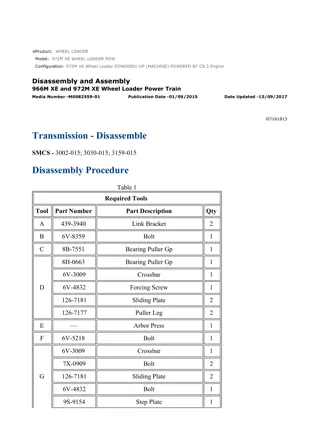

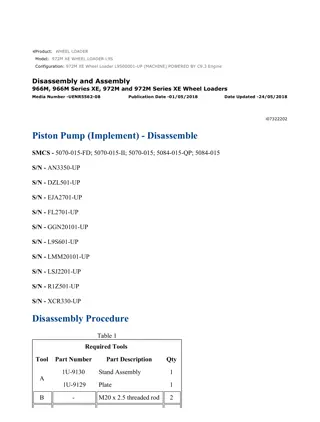

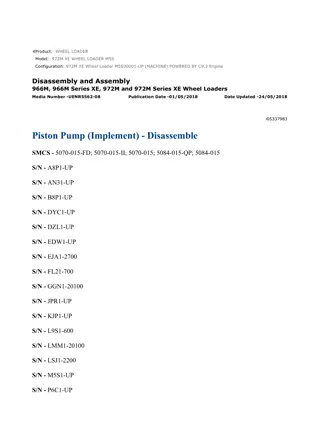

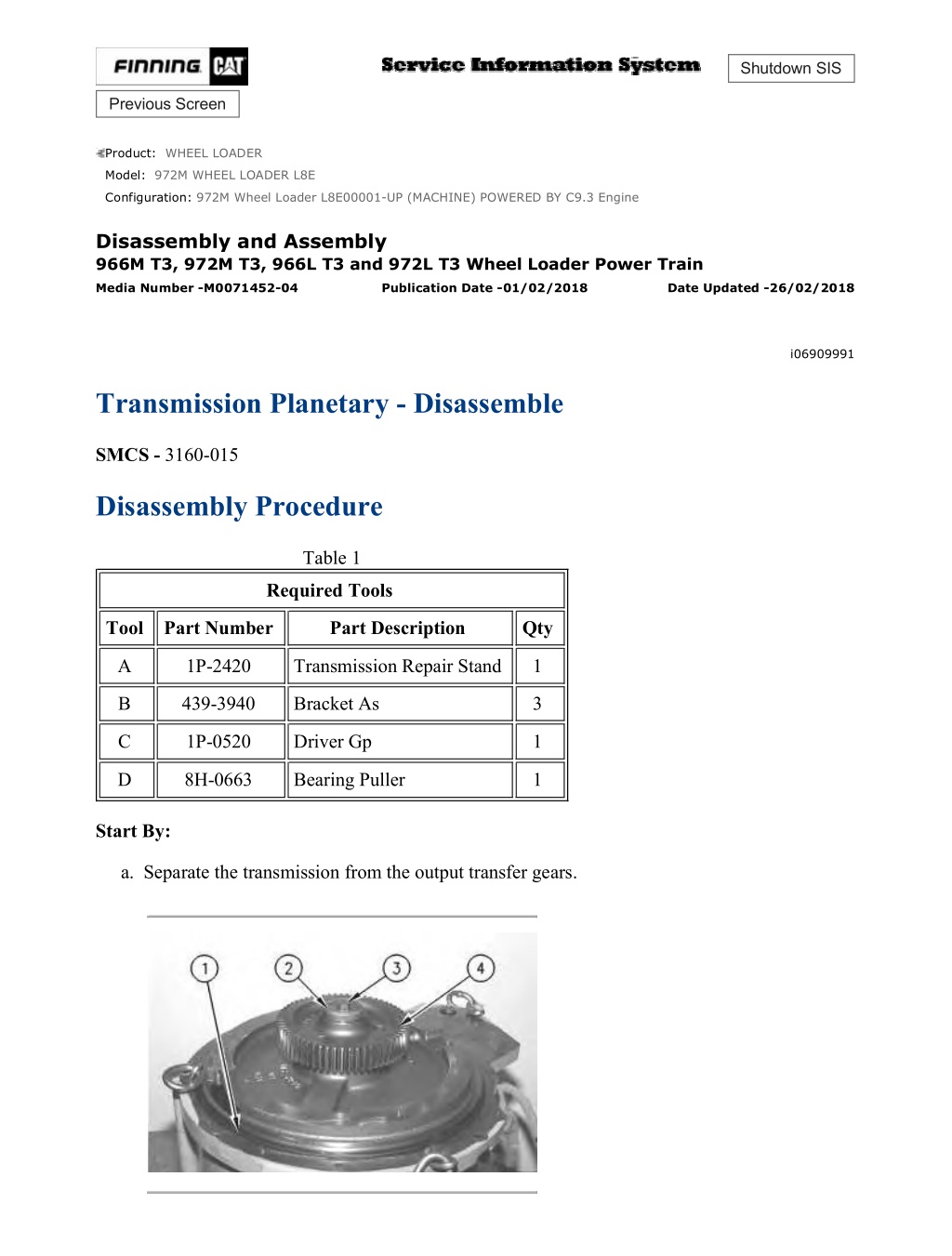

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 1/26 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 972M WHEEL LOADER L8E Configuration: 972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine Disassembly and Assembly 966M T3, 972M T3, 966L T3 and 972L T3 Wheel Loader Power Train Media Number -M0071452-04 Publication Date -01/02/2018 Date Updated -26/02/2018 i06909991 Transmission Planetary - Disassemble SMCS - 3160-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-2420 Transmission Repair Stand 1 B 439-3940 Bracket As 3 C 1P-0520 Driver Gp 1 D 8H-0663 Bearing Puller 1 Start By: a. Separate the transmission from the output transfer gears. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 2/26 Illustration 1 g00458960 1. Remove O-ring seal (1) from the housing. 2. Remove bolt (3), retainer (2), and drive gear (4) from the end of the input shaft. Illustration 2 g00459007 3. Remove plate (5). Illustration 3 g03370500 4. Attach Tooling (B) and a suitable lifting device to the transmission, as shown. The weight of the transmission is approximately 544 kg (1200 lb). 5. Carefully position the planetary group on the opposite end so that No. 6 clutch housing (6) is facing upward, as shown. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 3/26 Illustration 4 g00459073 6. Remove retaining ring (8) from output shaft (7). Illustration 5 g00459075 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 7. Remove bolts (9) and No. 6 clutch housing (6). Mark the location of the long bolts. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 4/26 Illustration 6 g00459079 8. Remove clutch piston (10) from No. 6 clutch housing (6). 9. Remove seal rings (11) and (12) from clutch piston (10). Illustration 7 g00459087 10. Remove clutch plate (14) and springs (13). Illustration 8 g00459090 11. Remove clutch plates (15) and friction discs (16). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 5/26 Illustration 9 g00459103 12. Remove ring gear (17). Remove transmission speed sensors (18). Illustration 10 g00459133 13. Remove carrier assembly (19). Illustration 11 g00459138 14. Remove metal seal ring (20) from carrier assembly (19). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 6/26 Illustration 12 g00459150 15. Use a hammer and a suitable punch to push the spring pins through carrier assembly (19) and into planetary shafts (21). Illustration 13 g00459151 16. Use a hammer and a suitable punch to remove planetary shafts (21) from carrier assembly (19). Illustration 14 g00324725 17. Remove thrust discs (22), planetary gears (23), and bearings (24) from the carrier assembly. Remove spring pins (25) from planetary shafts (21). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 7/26 Illustration 15 g00459161 18. Remove O-ring seal (26). Remove bolts (27) from manifold (28). Illustration 16 g00565113 19. Disconnect the harness assemblies which are attached to transmission modulating valves (29). Remove transmission modulating valves (29) from the transmission housing. Illustration 17 g03370508 20. Remove retaining ring (32) and gear (30). Remove retaining ring (31). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 8/26 Illustration 18 g03370929 21. Use Tooling (B) and a suitable lifting device to remove manifold (28). The weight of manifold (28) is approximately 85 kg (190 lb). 22. Remove bolt (33) which holds the harness assembly in place. Illustration 19 g00459352 23. Remove retaining ring (34) and bearing (35) from manifold (28). Illustration 20 g03370512 24. Remove retaining ring (36) and clutch housing (37). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 9/26 Illustration 21 g00459372 25. Remove O-ring seal (38) from clutch housing (37). Illustration 22 g00459375 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 26. Use steel spacers and a suitable press to push retainer plate (40). Remove retaining ring (39) from the clutch housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 10/26 Illustration 23 g00459387 27. Separate retaining ring (39), retainer plate (40), three coned disc springs (41), and clutch piston (42). Illustration 24 g00459393 28. Remove seal rings (43) from clutch piston (42). Illustration 25 g00459394 29. Remove seal rings (44) from clutch housing (37). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 11/26 Illustration 26 g03370877 30. Remove retaining ring (45) from the output shaft. Remove hub (46). Illustration 27 g03370887 31. Remove friction discs (47) and clutch plates (48). Illustration 28 g03370894 32. Remove clutch plate (49) and ring gear (50). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 12/26 Illustration 29 g00565193 33. Remove springs (51). Remove friction discs (52) and clutch plates (53). Illustration 30 g03370903 34. Remove clutch piston (54). Remove O-ring seals (55) and (56). Illustration 31 g00459506 35. Remove seal rings (57) and (58) from clutch piston (54). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 13/26 Illustration 32 g03370938 36. Use Tooling (B) and a suitable lifting device to remove housing (59). The weight of housing (59) is approximately 66 kg (145 lb). Note: The clutch piston may be stuck in housing (59). As housing (59) is removed, the clutch piston may fall. Illustration 33 g00565203 37. Remove clutch piston (60). Illustration 34 g00459540 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 14/26 38. Remove seal rings (61) and (62) from clutch piston (60). Illustration 35 g00565255 39. Remove friction discs (63) and clutch plates (64). Illustration 36 g00565689 40. Remove O-ring seals (65) and (66). Remove springs (68) and carrier assembly (69). Remove rods (67). Illustration 37 g00459619 41. Remove gear (70) from carrier assembly (69). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 15/26 Illustration 38 g00459622 42. Remove retaining ring (71) and bearing (72). Illustration 39 g00459634 43. Use several small steel rods (73) ( 3.175 mm (0.1250 inch) diameter and one pointed tip) to compress the retaining ring that holds carrier assembly (69) to ring gear (74). 44. Remove carrier assembly (69) from ring gear (74). Illustration 40 g00459638 45. Remove retaining ring (75) from carrier assembly (69). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 16/26 Illustration 41 g00459643 46. Use a hammer and a suitable punch to push the spring pins through carrier assembly (69) and into planetary shafts (76). 47. Use a hammer and a suitable punch to remove planetary shafts (76) from carrier assembly (69). Illustration 42 g00459646 48. Remove thrust discs (77), planetary gears (78), and bearings (79) from the carrier assembly. Remove spring pins (80) from planetary shafts (76). Illustration 43 g03371172 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 17/26 49. Remove retaining ring (81) that holds output shaft (7) to the input shaft. Remove output shaft (7). Illustration 44 g03371174 50. Remove O-ring seal (82) from output shaft (7). Illustration 45 g03371179 51. Remove retaining ring (85). 52. Remove sun gear (84) from output shaft (7). Illustration 46 g03371181 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 18/26 53. Use a suitable press to push output shaft (7) out of bearing (85), as shown. Illustration 47 g03371185 54. If necessary, remove bearings (86) from both ends of output shaft (7). Illustration 48 g03370976 55. Use Tooling (B) and a suitable lifting device to remove housing (87). The weight of housing (87) is approximately 61 kg (135 lb). Illustration 49 g03371190 56. Remove clutch piston (88), friction discs (89), and clutch plates (90). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 19/26 Illustration 50 g03371195 57. Remove seal rings (91) and (92) from clutch piston (88). Illustration 51 g03371199 58. Remove retaining ring (93) from the input shaft. 59. Remove springs (94) and ring gear (95). Remove O-ring seals (96) and (97). Illustration 52 g03371202 60. Remove carrier assembly (98) from the input shaft. The weight of carrier assembly (98) is approximately 29 kg (65 lb). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 20/26 Illustration 53 g03371205 61. Remove gear (99). 62. Place a suitable cribbing under carrier assembly (98). 63. Use several small steel rods (100) ( 2.36 mm (0.093 inch) diameter and one pointed tip) to compress the retaining ring that holds together carrier assembly (98) and ring gear (101). 64. Remove ring gear (101) from carrier assembly (98). Illustration 54 g03371214 65. Remove retaining ring (104) from carrier assembly (98). 66. Remove retaining ring (103). Remove sun gear (102) and the bearing. Use Tooling (C) to remove sun gear (102) and the bearing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 21/26 Illustration 55 g03371218 67. Use a hammer and a suitable punch to push the spring pins through carrier assembly (98) and into planetary shafts (105). Illustration 56 g03371226 68. Use a hammer and a suitable punch to remove planetary shafts (105) from carrier assembly (98). Illustration 57 g03371228 69. Remove thrust discs (106), bearings (108), and planetary gears (107) from the carrier assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 22/26 70. Remove spring pins (109) from planetary shafts (105). Illustration 58 g03371234 71. Remove bearing (110) from sun gear (102). Illustration 59 g03371237 72. Remove O-ring seal (111) from sun gear (102). Illustration 60 g03371261 73. Remove plate (112). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 23/26 Illustration 61 g03371265 74. Remove friction discs (113) and clutch plates (116). Remove O-ring seals (114) and (115). Illustration 62 g03371267 75. Use several small steel rods (117) ( 2.36 mm (0.093 inch) diameter and one pointed tip) to compress the retaining ring that holds coupling (119) to carrier assembly (118). Remove coupling (119) from carrier assembly (118). Note: Coupling (119) and carrier assembly (118) may be removed together at this time. Use small steel rods (117) to separate coupling (119) and carrier assembly (118). See Step 43 for similar actions. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 24/26 Illustration 63 g03371091 76. Remove clutch piston (120) from the clutch housing. Remove carrier assembly (118). Illustration 64 g03371274 77. Remove seal rings (121) and (122) from clutch piston (120). Illustration 65 g03371276 78. Remove retaining ring (123). Use Tooling (C) to remove bearing (124). 79. Remove seal ring (125) from carrier assembly (118). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 25/26 Illustration 66 g03371282 80. Use a hammer and a suitable punch to push the spring pins through carrier assembly (118) and into planetary shafts (126). 81. Use a hammer and a suitable punch to remove planetary shafts (126) from carrier assembly (118). Illustration 67 g03371287 82. Remove thrust discs (127), planetary gears (128), and bearings (129) from the carrier assembly. Remove spring pins (130) from planetary shafts (126). Illustration 68 g03371291 83. Remove retaining ring (131) from housing (132). 84. Use a soft hammer to remove input shaft (133) from housing (132). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M0... 26/26 Illustration 69 g03371296 85. Remove ring seals (135) and O-ring seal (136) from input shaft (133). Remove bearing (134). Illustration 70 g03370990 86. Use a suitable press and Tooling (D) to remove race (137) from input shaft (133). Copyright 1993 - 2021 Caterpillar Inc. Sun Apr 4 07:46:30 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

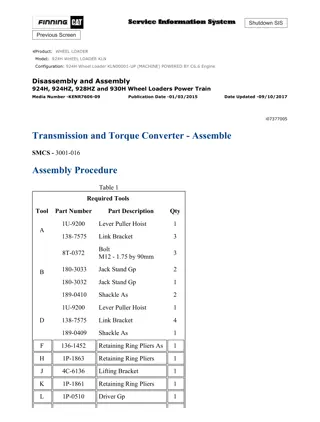

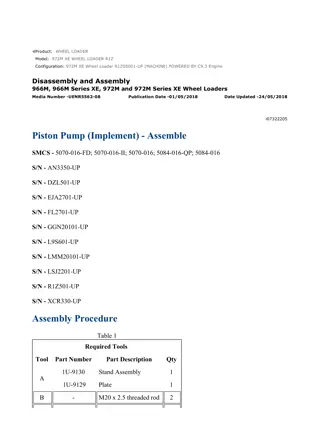

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 1/28 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 972M WHEEL LOADER L8E Configuration: 972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine Disassembly and Assembly 966M T3, 972M T3, 966L T3 and 972L T3 Wheel Loader Power Train Media Number -M0071452-04 Publication Date -01/02/2018 Date Updated -26/02/2018 i06910646 Transmission Planetary - Assemble SMCS - 3160-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-2420 Transmission Repair Stand 1 B 439-3940 Bracket As 3 C 1P-0520 Driver Gp 1 E FT-2746 Guide Pin 2 F 1P-0510 Driver Gp 1 Note: Cleanliness is an important factor. Before assembly, all parts should be cleaned in cleaning fluid. Allow the parts to air dry. Do not use wiping cloths or rags to dry parts. Lint may be deposited on the parts. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 2/28 Illustration 1 g03371296 Note: O-ring seal (136) is not installed at this time. The O-ring seal is shown to clarify the installation in Step 11. 1. Raise the temperature of bearing (134) and the race. Install bearing (134) and the race onto input shaft (133), as shown. 2. Apply clean transmission oil to ring seals (135). Install ring seals (135) on input shaft (133). Illustration 2 g03371291 3. Carefully install input shaft (133) in housing (132). 4. Install retaining ring (131) to hold the input shaft and the bearing in place. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 3/28 Illustration 3 g03371287 Illustration 4 g03371282 5. Install bearings (129) in planetary gears (128). Install the gear assemblies, thrust discs (127), and planetary shafts (126) in carrier assembly (118). 6. Use a hammer and a suitable punch to install spring pins (130) that hold planetary shafts (126) in carrier assembly (118). Make sure that the spring pins are flush with the counterbore in the carrier. Illustration 5 g03371276 7. Install seal ring (125) on carrier assembly (118). 8. Use Tooling (C) to install bearing (124). Install retaining ring (123). Note: Coupling (119) may be installed on carrier assembly (118) now. Refer to Step 13 for the procedure. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 4/28 Illustration 6 g03371274 9. Install seal rings (121) and (122) on clutch piston (120). Illustration 7 g03371091 10. Place the housing onto Tooling (A). Install clutch piston (120) in the clutch housing. Make sure that the lips of the seals are facing downward. 11. Install O-ring seal (136). Apply clean transmission oil to O-ring seal (136) and the O-ring seal groove on the shaft. Refer to Illustration 1 for the location of the O-ring seal. 12. Install carrier assembly (118). Illustration 8 g03371267 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 5/28 13. If necessary, install coupling (119) on carrier assembly (118). Use small steel rods (117) to compress the retaining ring that holds coupling (119) to carrier assembly (118). Illustration 9 g03371339 Illustration 10 g03371144 Note: For assembly purposes, use Tooling (E) to hold the clutch plates in place. Do not remove Tooling (E) until Step 85 is completed. 14. Install one clutch plate (116) in the housing so that the small hole in the clutch plate is aligned with the small hole in the housing, as shown. 15. Install Tooling (E) in two of the five threaded holes in the housing through clutch plate (116), as shown. Do not remove Tooling (E) until Step 85 is completed. 16. Install friction discs (113) and clutch plates (116) in alternating order. Start with a friction disc. Install clutch plates (116) so that Tooling (E) passes through the bolt holes in the clutch plates. Install the clutch plates with the small holes on the opposite side of Tooling (E) in comparison to the first clutch plate (116) that was installed in Step 14. 17. Install O-ring seals (114) and (115). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 6/28 Illustration 11 g03371261 18. Install plate (112). Illustration 12 g03371228 Illustration 13 g03371218 19. Install bearings (108) in planetary gears (107). Install the gear assemblies, thrust discs (106), and planetary shafts (105) in carrier assembly (98). 20. Use a hammer and a suitable punch to install spring pins (109) that hold planetary shafts (105) in carrier assembly (98). Make sure that the spring pins are flush with the counterbore in the carrier. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

972M Wheel Loader L8E00001-UP (MACHINE) POWERED BY C9.3 Engine(M006... 7/28 Illustration 14 g03371237 Illustration 15 g03371347 21. Use Tooling (C) and a suitable press to install bearing (110). Install retaining ring (103). 22. Install O-ring seal (111) on sun gear (102). Apply clean transmission oil to O-ring seal (111) and the O-ring seal groove on sun gear (102). 23. Install sun gear (102) in carrier assembly (98). 24. Install retaining ring (104) on carrier assembly (98). Illustration 16 g03371205 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisw... 2021/4/4

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com