Caterpillar Cat 966F II WHEEL LOADER (Prefix 1SL) Service Repair Manual Instant Download (1SL00001-00506)

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

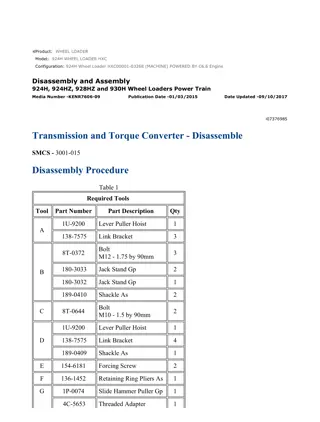

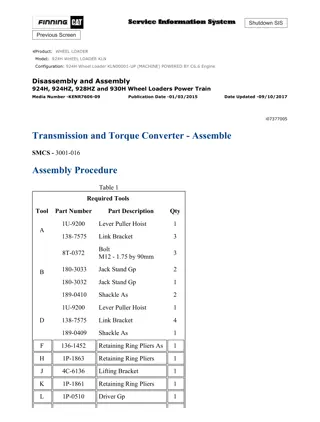

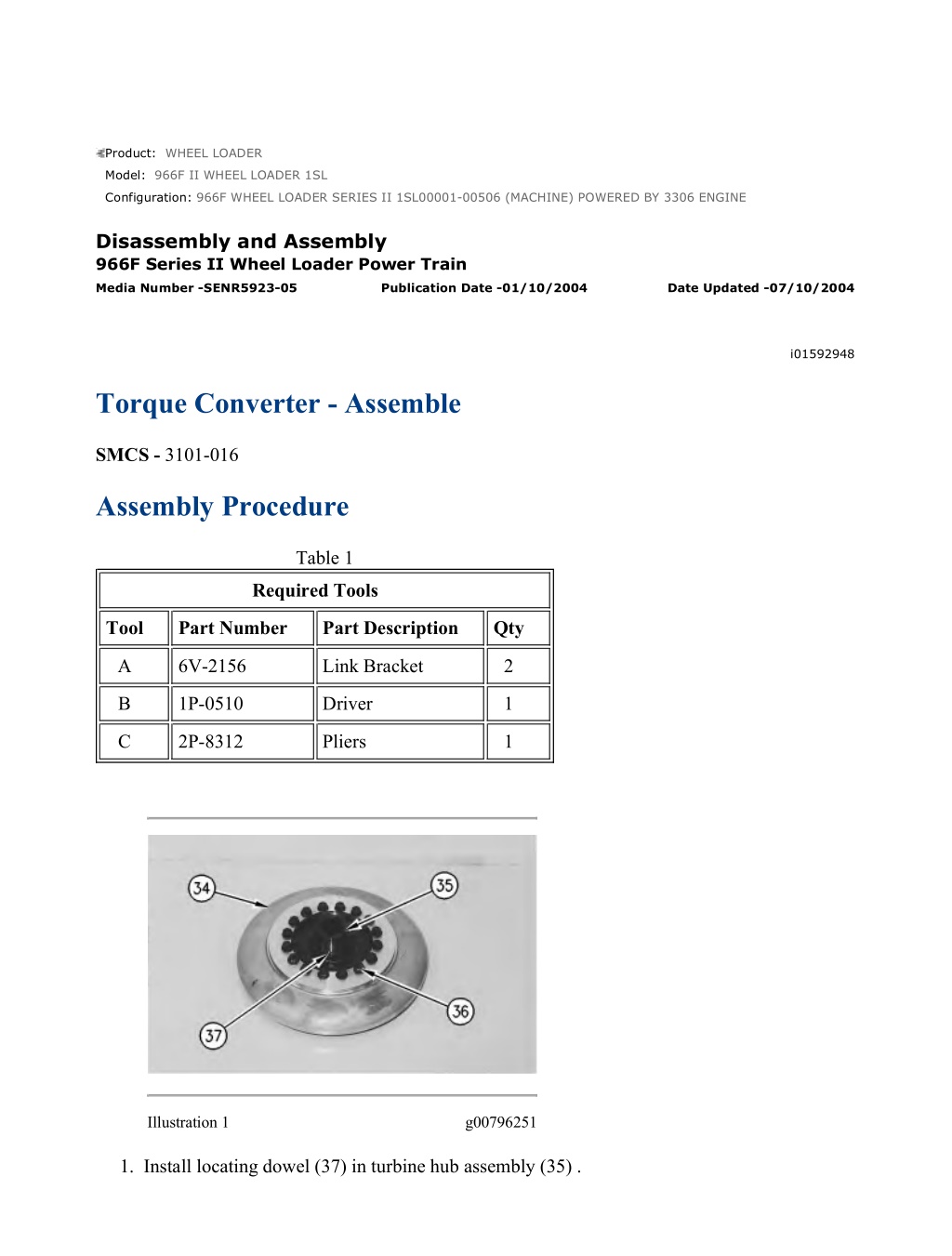

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 1/13 Product: WHEEL LOADER Model: 966F II WHEEL LOADER 1SL Configuration: 966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3306 ENGINE Disassembly and Assembly 966F Series II Wheel Loader Power Train Media Number -SENR5923-05 Publication Date -01/10/2004 Date Updated -07/10/2004 i01592948 Torque Converter - Assemble SMCS - 3101-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 6V-2156 Link Bracket 2 B 1P-0510 Driver 1 C 2P-8312 Pliers 1 Illustration 1 g00796251 1. Install locating dowel (37) in turbine hub assembly (35) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 2/13 2. Install turbine hub assembly (34) to converter turbine (34). Install sixteen bolts (36) and the washers. The torque for bolts (36) is 60 7 N m (44 5 lb ft). Illustration 2 g00796189 3. Raise converter turbine (34) on a bench, and install the rotating housing (32) over converter turbine (34), as shown. Note: Be careful not to pinch your fingers when you lower rotating housing (32) over converter turbine (34) . Illustration 3 g00458110 Note: The notch on bearing (38) must be aligned with locating dowel (37) on turbine hub assembly (35) . 4. Install bearing (38) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 3/13 Illustration 4 g00496512 5. Install the bearing spacer. 6. Use Tooling (C) in order to install retaining ring (33) on the turbine hub assembly. Retaining ring (33) must be securely seated in the groove. Illustration 5 g00496510 7. Install the O-ring seal, end cover (31), and retaining ring (30) to housing (32) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 4/13 Illustration 6 g00496508 8. Lower the temperature of bearing (27). Install the bearing in impeller (24) . Note: The notch in bearing (29) must face upward, as shown. Illustration 7 g00496086 9. Install drive gear (26) and eight bolts (25) to impeller (24). Tighten the bolts to a torque of 105 15 N m (77 11 lb ft). Illustration 8 g00796386 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 5/13 Illustration 9 g00796190 10. Install seal ring (40) on carrier assembly (23). Put clean oil on the seal ring. Note: The notch on bearing (27) must be aligned with the locating dowel on carrier assembly (23) . 11. Install torque converter impeller (24) on carrier assembly (23) . Illustration 10 g00495999 12. Install spacer (22). Use Tooling (C) to install retaining ring (21) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 6/13 Illustration 11 g00495924 13. Install one retaining ring (19) and heat stator (18) to a temperature of 121 C (250 F). Maintain the temperature for one hour. Install splined hub (20) in stator (18) before the stator is allowed to cool. Install second retaining ring (19) to the other side of stator (18) in order to hold the unit together. Illustration 12 g00796393 14. Install stator (18) on the impeller. 15. Install retaining ring (17) on the end of the carrier assembly (23) in order to hold the stator. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 7/13 Illustration 13 g00496607 16. Install seal ring (29) on output shaft (15) . Note: Use steps 17 through 19 for the installation of a split bearing assembly (newer models). Illustration 14 g00796206 17. Install piston ring (39) on output shaft (15) . 18. Use a press in order to install the bearing inner race of bearing (28) with the flange side downward on output shaft (15) . 19. Install bearing (28) on output shaft (15), and install output shaft (15) in carrier assembly (23) . Note: Use steps 20 and 21 for the installation of a single bearing assembly (older models). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 8/13 Illustration 15 g00840905 20. Install bearing (28) on output shaft (15) . 21. Use Tooling (C) in order to install the retaining ring on output shaft (15) . Illustration 16 g00495888 22. Install output shaft (15) and retaining ring (16) to the carrier assembly. Illustration 17 g00496619 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 9/13 23. Install two M10 guide bolts in the housing. Fasten Tooling (A) and a hoist to the impeller (24), as shown. Position the impeller (24) on the housing. 24. Install the 18 bolts and the washers that hold the unit together. Tighten the bolts to a torque of 60 7 N m (44 5 lb ft). Illustration 18 g00496645 25. Install ring (42). Put clean oil on the ring. Illustration 19 g00495765 26. Install retainer (13) on gear (10) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED B... 10/13 Illustration 20 g00496649 27. Heat bearing (12) to a maximum temperature of 135 C (275 F). Install bearing (12) on gear (10) . Illustration 21 g00495693 28. Install retaining ring (11) that holds bearing (12) on gear (10) . Illustration 22 g00495692 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED B... 11/13 29. Install transmission oil pump drive gear (10) on the torque converter housing. Illustration 23 g00495690 30. Install tube assembly (7). Install six bolts (8) and the washers. Tighten the bolts to a torque of 50 7 N m (37 5 lb ft). Install shaft (9) into the gear. Illustration 24 g00496685 31. Put clean oil on the O-ring seal. Install transmission oil pump (6) in the torque converter housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED B... 12/13 Illustration 25 g00495685 32. Fasten Tooling (A) and a hoist to torque converter housing (4), as shown. Put the torque converter housing in position on the torque converter. The weight of the torque converter housing is 113 kg (250 lb). Illustration 26 g00496688 33. Install guide bolts (43), as shown. Align the bolt holes in the carrier and the housing. Install bolts (5) that hold the carrier to the housing. Tighten the bolts to a torque of 50 7 N m (37 5 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED B... 13/13 Illustration 27 g00495677 34. Install gear (3), retainer (2) and the bolt. Tighten the bolt to a torque of 120 15 N m (90 11 lb ft). 35. Put clean oil on O-ring seals (1). Install the O-ring seals (1) on the torque converter housing. End By: Connect the torque converter to the transmission. Refer to Disassembly and Assembly, "Torque Converter to Transmission, Output Transfer Gears - Connect". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 1/3 Product: WHEEL LOADER Model: 966F II WHEEL LOADER 1SL Configuration: 966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3306 ENGINE Disassembly and Assembly 966F Series II Wheel Loader Power Train Media Number -SENR5923-05 Publication Date -01/10/2004 Date Updated -07/10/2004 i00957476 Transmission from Output Transfer Gears - Separate SMCS - 3002-076 Separation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 5P-9736 Link Bracket 3 Start By: A. Remove the transmission hydraulic control valve. Refer to Disassembly and Assembly, "Transmission Hydraulic Control Valve - Removal". B. Separate the torque converter from the transmission. Refer to Disassembly and Assembly, "Torque converter from Transmission, Output Transfer Gears - Separate". NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the machine. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Caterpillar Tools and Shop Products Guide", for tools and supplies suitable to collect and contain fluids in Caterpillar machines. Dispose of all fluids according to local regulations and mandates. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 2/3 Note: Put identification marks on all lines, on all hoses, on all wires, and on all tubes for installation purposes. Plug all lines, all hoses and all tubes. This helps to prevent fluid loss and this helps to keep contaminants from entering the system. 1. Thoroughly clean the outside of the torque converter, the outside of the transmission and the output gears prior to disassembly. 2. Drain the transmission oil into a suitable container. The capacity of the transmission is 46 L (12 US gal). Illustration 1 g00488067 3. Fasten Tooling (A) and a hoist, as shown. Remove the bolts that hold the transmission and case (1) to the transfer gear case. Use two 3/8" - 16 NC forcing screws to separate the transmission from the transfer gear case. The weight of the unit is 544 kg (1200 lb). Illustration 2 g00488075 4. Remove O-ring seals (2) and (3) from transmission case (1) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 1/27 Model: 966F II WHEEL LOADER 1SL Configuration: 966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3306 ENGINE Disassembly and Assembly 966F Series II Wheel Loader Power Train Media Number -SENR5923-05 Publication Date -01/10/2004 Date Updated -07/10/2004 i00961675 Transmission Planetary - Disassemble SMCS - 3160-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 5P-9736 Link Bracket 3 B 6V-2156 Link Bracket 3 C FT-0833 Clamp 2 D 1P-1863 Pliers 1 E 5P-4758 Pliers 1 F 2P-8312 Pliers 1 G FT-0947 Clamp 2 H 1P-0520 Driver 1 J 1P-1862 Pliers 1 K 8H-0663 Bearing Puller 1 L 1P-1861 Pliers 1 Start By: A. Remove the transmission hydraulic control valve. Refer to Disassembly and Assembly, "Transmission Hydraulic Control Valve - Remove". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 2/27 B. Separate the torque converter from the transmission. Refer to Disassembly and Assembly, "Torque Converter from Transmission, Output Transfer Gears - Separate". C. Separate the transmission from the output transfer gears. Refer to Disassembly and Assembly, "Transmission from Output Transfer Gears - Separate". Note: Cleanliness is an important factor. Before the disassembly procedure, the exterior of the component should be thoroughly cleaned. This will help to prevent dirt from entering the internal mechanism. Illustration 1 g00490174 1. Fasten Tooling (A) and a hoist to case (1), as shown. Remove the bolts that hold case (1) to the manifold. Use two 3/8" - 16 NC forcing screws to separate case (1) from the manifold. Remove case (1) from the transmission. The weight of the case is 91 kg (200 lb). Illustration 2 g00490206 2. Remove elbow (5) and the O-ring seal from the reverse clutch housing. 3. Remove the bolt, retainer (6) and gear (7) from the transmission input shaft. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

Suggest: For more complete manuals. Please go to the home page. https://www.ebooklibonline.com If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 3/27 Illustration 3 g00490222 4. Use a hoist to turn the transmission, as shown. The weight of the transmission is 453 kg (1000 lb). 5. Remove O-ring seal (10) and two O-ring seals (9) . Note: Put alignment marks across the clutch housings for assembly purposes. Illustration 4 g00490238 6. Install Tooling (C) in order to hold the piston in the No. 6 clutch housing (11) . 7. Fasten Tooling (B) and a hoist to clutch housing (11). Remove bolts (8). Remove clutch housing (11) from the transmission. The weight of the clutch housing is 27 kg (60 lb). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

966F WHEEL LOADER SERIES II 1SL00001-00506 (MACHINE) POWERED BY 3... 4/27 Illustration 5 g00490267 8. Remove clutch piston (12) from clutch housing (11). Remove the seal rings from the clutch piston. Illustration 6 g00490270 9. Remove reaction dowels (14), springs (15), three friction discs (13) and the two clutch plates from the manifold. Illustration 7 g00490271 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2022/5/10

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com