Caterpillar Cat 962H Wheel Loader (Prefix K6K) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Service Repair Manual Models 962H WHEEL LOADER

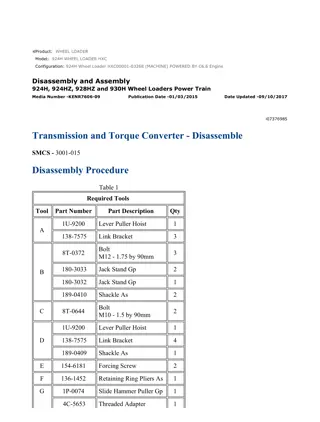

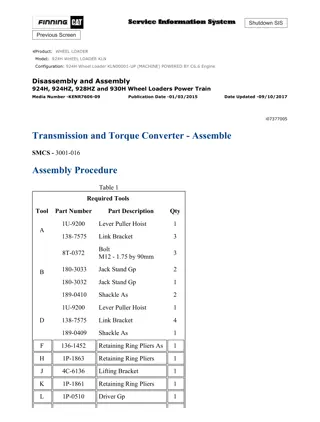

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 1/3 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 962H WHEEL LOADER K6K Configuration: 962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine Disassembly and Assembly IT62H Integrated Toolcarrier and 950H and 962H Wheel Loaders Machine Systems Media Number -RENR8881-01 Publication Date -01/06/2009 Date Updated -08/06/2009 i02362322 Pilot Valve (Command Control Steering) - Remove SMCS - 4342-011 Removal Procedure Start By: A. Connect the steering frame lock. Refer to Disassembly and Assembly, "Steering Frame Lock - Separate and Connect". B. Release the pressure in the hydraulic system. Refer to Disassembly and Assembly, "System Pressure - Release". Note: Cleanliness is an important factor. Before the disassembly procedure, the exterior of the component should be thoroughly cleaned. This will help to prevent dirt from entering the internal mechanism. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Caterpillar Tools and Shop Products Guide" for tools and supplies suitable to collect and contain fluids on Caterpillar products. Dispose of all fluids according to local regulations and mandates. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 2/3 Hot oil and hot components can cause personal injury. Do not allow hot oil or hot components to contact skin. Note: Put identification marks on all hoses and on all wires for installation purposes. Plug all hoses. This will help to prevent fluid loss and this will help to keep contaminants from entering the system. Illustration 1 g00439803 1. Remove the nut and bolt (2) . 2. Remove bottom shaft yoke (1) from the shaft of the steering pilot valve. Illustration 2 g00439805 3. Disconnect steering shaft (3) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 3/3 Illustration 3 g00493363 4. Disconnect hose assemblies (4) . Illustration 4 g00493364 5. Remove bolts (5) . 6. Remove steering pilot valve (6) . Copyright 1993 - 2020 Caterpillar Inc. Thu Mar 26 11:56:22 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

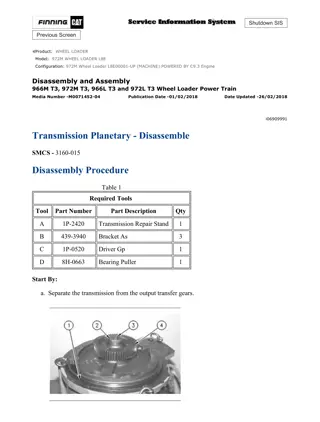

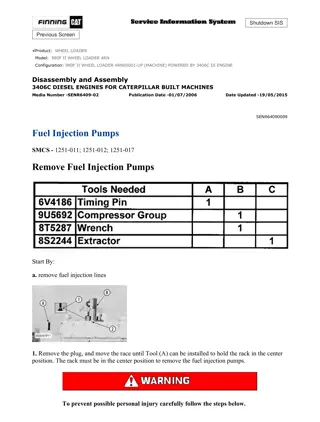

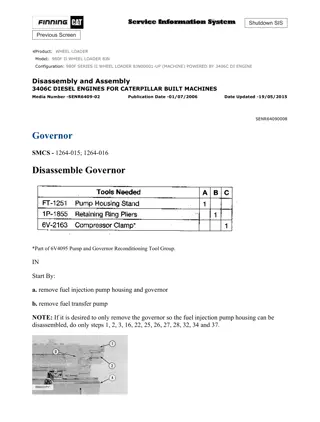

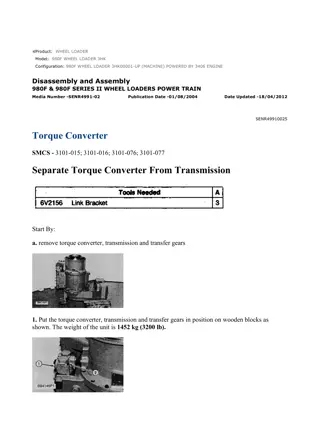

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 1/11 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 962H WHEEL LOADER K6K Configuration: 962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine Disassembly and Assembly IT62H Integrated Toolcarrier and 950H and 962H Wheel Loaders Machine Systems Media Number -RENR8881-01 Publication Date -01/06/2009 Date Updated -08/06/2009 i02330782 Pilot Valve (Command Control Steering) - Disassemble SMCS - 4342-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty 2M-0849 Washer 2 6B-6684 Nut 2 6V-2360 Washer 1 126-7176 Forcing Screw 1 A 126-7177 Puller Leg 2 126-7181 Sliding Plate 2 126-7182 Nut 1 126-7183 Crossblock 1 Start By: a. Remove the steering pilot valve. Refer to Disassembly and Assembly, "Pilot Valve (Steering) - Remove". Note: Cleanliness is an important factor. Before the disassembly procedure, the exterior of the component should be thoroughly cleaned. This will help to prevent dirt from entering the internal mechanism. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 2/11 Illustration 1 g00448798 1. Place the steering pilot valve in the position, as shown. Illustration 2 g00448799 2. Remove bolts (4) and valve body assembly (3) from main body assembly (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 3/11 3. Remove plunger (2). Illustration 3 g00448800 4. Remove O-ring seals (5) and O-ring seal (6) from valve body assembly (3). Illustration 4 g00842709 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 4/11 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 5. Remove plug (11). 6. Remove O-ring seal (12) from plug (11). 7. Remove sleeve (13). 8. Remove slug (14) and stem assembly (15). 9. Remove retaining ring (10), retainer (9), and spring (8) from stem (7). 10. Remove spring (16) from valve body assembly (3). Illustration 5 g00448823 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 5/11 11. Remove bolts (17). Illustration 6 g00842724 12. Remove cover (18) and O-ring seal (19). Note: Note the location of Hole (X) and Hole (Y). 13. Remove spool (20). 14. Remove ring (21) and O-ring seal (22). 15. Remove two bolts (23) and bolt (24) from upper body assembly (25). 16. Remove upper body assembly (25) from lower body assembly (27). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 6/11 17. Remove O-ring seal (26). Illustration 7 g00448825 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. Note: The ends of spring (29) must be spread in order to remove shaft assembly (28). 18. Use two screwdrivers in order to spread the ends of spring (29). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 7/11 Illustration 8 g00448826 19. Remove shaft assembly (28) from lower body assembly (27). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 8/11 Illustration 9 g00448827 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 9/11 Illustration 10 g00448828 20. Remove retaining ring (30), cam (31), and key (32) from shaft assembly (28). 21. Use Tooling (A) to remove ball bearings (33) from shaft assembly (28). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEB... 10/11 Illustration 11 g00448829 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 22. Remove spring (29) from shaft assembly (28). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEB... 11/11 Illustration 12 g00448831 23. Remove lip seal (34) from lower body assembly (27). Copyright 1993 - 2020 Caterpillar Inc. Thu Mar 26 11:57:19 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

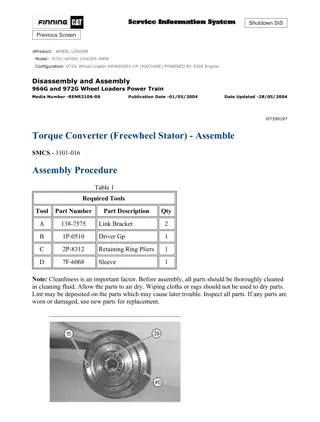

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 1/12 Shutdown SIS Previous Screen Product: WHEEL LOADER Model: 962H WHEEL LOADER K6K Configuration: 962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine Disassembly and Assembly IT62H Integrated Toolcarrier and 950H and 962H Wheel Loaders Machine Systems Media Number -RENR8881-01 Publication Date -01/06/2009 Date Updated -08/06/2009 i02330785 Pilot Valve (Command Control Steering) - Assemble SMCS - 4342-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-0510 Driver Group 1 Note: Cleanliness is an important factor. Before assembly, all parts should be thoroughly cleaned in cleaning fluid. Allow the parts to air dry. Wiping cloths or rags should not be used to dry parts. Lint may be deposited on the parts which may cause later trouble. Inspect all parts. If any parts are worn or damaged, use new parts for replacement. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 2/12 Illustration 1 g00448939 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 3/12 Illustration 2 g00448831 1. Use a suitable press and Tooling (A) to install lip seal (34) in lower body assembly (27). 2. Apply clean hydraulic oil to the sealing lip of lip seal (34). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 4/12 Illustration 3 g00448829 Improper assembly of parts that are spring loaded can cause bodily injury. To prevent possible injury, follow the established assembly procedure and wear protective equipment. 3. Install spring (29) on shaft assembly (28). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 5/12 Illustration 4 g01122933 4. Raise the temperature of ball bearings (33) to 135 C (275 F). 5. Use insulated gloves to install ball bearings (33) on shaft assembly (28). 6. Install key (32), cam (31), and retaining ring (30) on shaft assembly (28). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 6/12 Illustration 5 g00448826 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 7/12 Illustration 6 g00448825 Improper assembly of parts that are spring loaded can cause bodily injury. To prevent possible injury, follow the established assembly procedure and wear protective equipment. Note: The ends of spring (29) must be spread in order to install shaft assembly (28). 7. Use two screwdrivers in order to spread the ends of spring (29). 8. Install shaft assembly (28) in lower body assembly (27). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 8/12 Illustration 7 g00842724 9. Apply clean hydraulic oil to O-ring seal (26). Install O-ring seal (26). 10. Install upper body assembly (25) on lower body assembly (27). 11. Install bolts (23) and bolt (24) in upper body assembly (25). 12. Apply clean hydraulic oil to O-ring seal (22). Install O-ring seal (22) and ring (21). Note: Spool (20) must be oriented so that Hole (X) is aligned with Hole (Y) in the upper body assembly, as shown. 13. Install spool (20). The spool must fit freely over the male spline on the shaft assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEBP3... 9/12 14. Apply clean hydraulic oil to O-ring seal (19). Install O-ring seal (19) and cover (18). Illustration 8 g00448823 15. Install bolts (17). The torque for bolts (17) is 55 7 N m (41 5 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEB... 10/12 Illustration 9 g00842709 Improper assembly of parts that are spring loaded can cause bodily injury. To prevent possible injury, follow the established assembly procedure and wear protective equipment. 16. Install spring (16). 17. Install spring (8), retainer (9), and retaining ring (10) on stem (7). 18. Install stem assembly (15) and slug (14). 19. Install sleeve (13). 20. Apply clean hydraulic oil to O-ring seal (12). Install O-ring seal (12) on plug (11). 21. Install plug (11). The torque for plug (11) is 80 7 N m (59 5 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

962H Wheel Loader K6K00001-UP (MACHINE) POWERED BY C7 Engine(SEB... 11/12 Illustration 10 g00448800 22. Apply clean hydraulic oil to O-ring seals (5) and O-ring seal (6). Install O-ring seals (5) and O-ring seal (6) on valve body assembly (3). Illustration 11 g00448799 23. Install plunger (2). 24. Install valve body assembly (3) and two bolts (4) on main body assembly (1). End By: a. Install the steering pilot valve. Refer to Disassembly and Assembly, "Pilot Valve (Steering) - Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/3/26

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com