Caterpillar Cat 637E WHEEL TRACTOR (Prefix 1FB) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

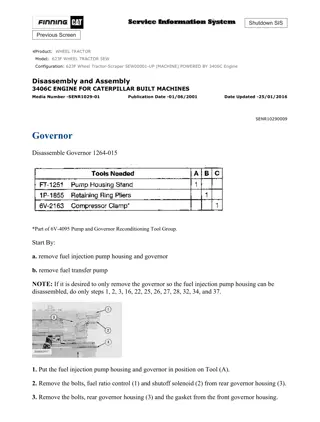

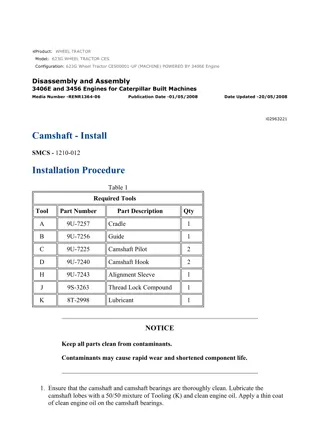

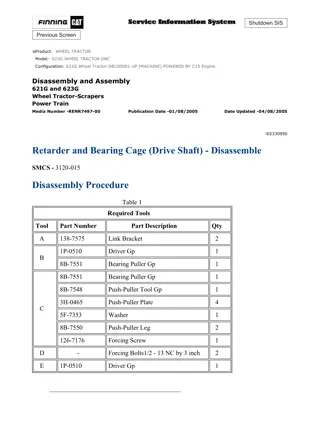

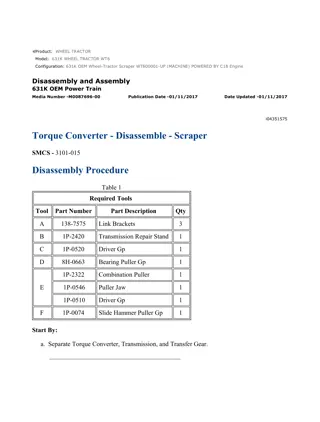

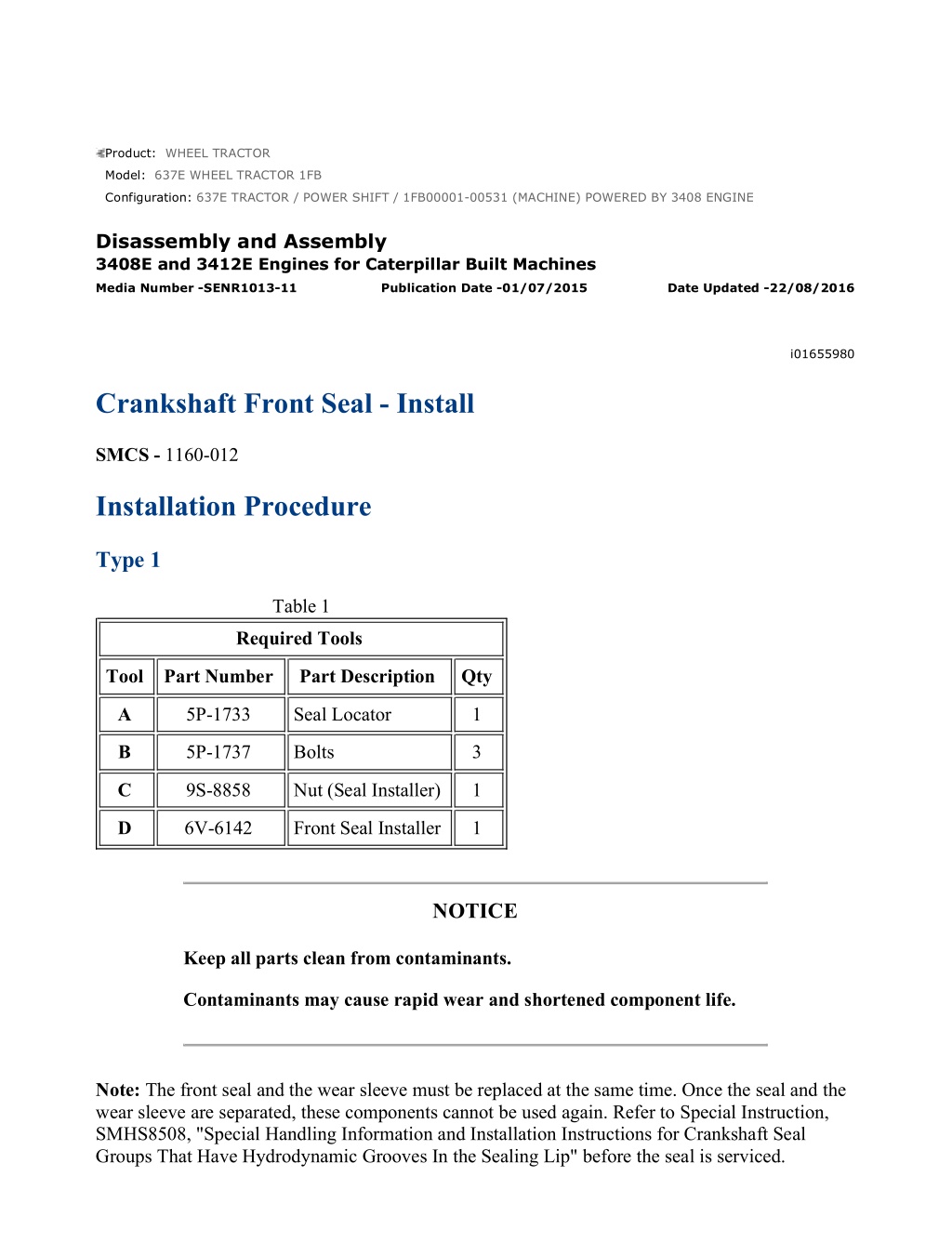

w 1/6(W) Product: WHEEL TRACTOR Model: 637E WHEEL TRACTOR 1FB Configuration: 637E TRACTOR / POWER SHIFT / 1FB00001-00531 (MACHINE) POWERED BY 3408 ENGINE Disassembly and Assembly 3408E and 3412E Engines for Caterpillar Built Machines Media Number -SENR1013-11 Publication Date -01/07/2015 Date Updated -22/08/2016 i01655980 Crankshaft Front Seal - Install SMCS - 1160-012 Installation Procedure Type 1 Table 1 Required Tools Tool Part Number Part Description Qty A 5P-1733 Seal Locator 1 B 5P-1737 Bolts 3 C 9S-8858 Nut (Seal Installer) 1 D 6V-6142 Front Seal Installer 1 NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Note: The front seal and the wear sleeve must be replaced at the same time. Once the seal and the wear sleeve are separated, these components cannot be used again. Refer to Special Instruction, SMHS8508, "Special Handling Information and Installation Instructions for Crankshaft Seal Groups That Have Hydrodynamic Grooves In the Sealing Lip" before the seal is serviced. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

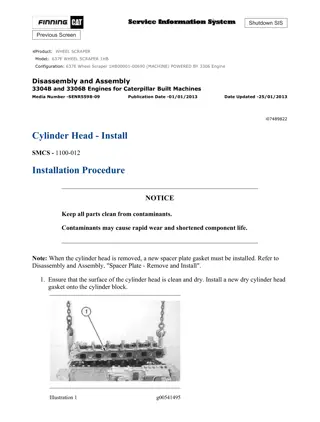

w 2/6(W) Note: Do not use any type of lubricant during the installation of the crankshaft seal and the wear sleeve. 1. Before installation of the crankshaft seal and the wear sleeve, inspect the crankshaft for scratches. Also, inspect the crankshaft for any distortion on the surface that may lead to an out of round condition. Use a polishing cloth in order to remove any imperfections on the crankshaft. 2. Use 4C-9500 Quick Cure Primer to clean the outside diameter of the crankshaft and the inside diameter of wear sleeve (1). 3. Apply 4C-9507 Retaining Compound to the outside diameter of the crankshaft. Apply 4C- 9507 Retaining Compound to the inside diameter of wear sleeve (1). Illustration 1 g00829187 Type 1 seal design. (1) Seal (2) Wear sleeve https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 3/6(W) Illustration 2 g00829675 Typical example 4. Fasten Tool (A) to the crankshaft with Tool (B). NOTICE The front and rear seals and wear sleeves have different spiral grooves in the seal. Because of this type of design, the front seal group for an engine is different from the rear seal group. If a seal group is installed on the wrong end of the engine, oil can actually be taken out of the engine instead of moving oil back into the engine. Illustration 3 g00515623 Note: Install the seal with the arrow that shows the direction of crankshaft rotation toward the front of the engine. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

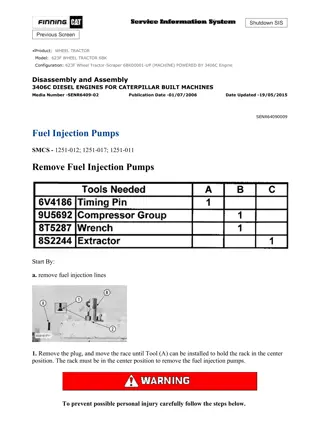

w 4/6(W) 5. Position wear sleeve (2) and seal (1) on Tool (A). Install Tool (D) on Tool (A). Lubricate the face of the washer on Tool (C). Install Tool (C) on Tool (A). 6. Tighten Tool (C) until Tool (D) contacts Tool (A). 7. Remove Tools (A), (B), (C), and (D). Check the crankshaft seal and the wear sleeve for the correct installation. Type 2 Table 2 Required Tools Tool Part Number Part Description Qty A 5P-1733 Seal Locator 1 B 5P-1737 Bolts 3 C 9S-8858 Nut (Seal Installer) 1 D 6V-6142 Front Seal Installer 1 NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Note: The front seal and the wear sleeve must be replaced at the same time. Once the seal and the wear sleeve are separated, these components cannot be used again. Refer to Special Instruction, SMHS8508, "Special Handling Information and Installation Instructions for Crankshaft Seal Groups That Have Hydrodynamic Grooves In the Sealing Lip" before the seal is serviced. Note: Do not use any type of lubricant during the installation of the crankshaft seal and the wear sleeve. 1. Before installation of the crankshaft seal and the wear sleeve, inspect the crankshaft for scratches. Also, inspect the crankshaft for any distortion on the surface that may lead to an out of round condition. Use a polishing cloth in order to remove any imperfections on the crankshaft. 2. Use 4C-9500 Quick Cure Primer to clean the outside diameter of the crankshaft. Note: The type 2 seal comes with the 4C-9507 Retaining Compound that is already applied to the inside diameter of the wear sleeve. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 5/6(W) Illustration 4 g00829143 Type 2 seal design. (1) Seal (2) Wear sleeve flange (3) Wear sleeve Illustration 5 g00829675 Typical example 3. Fasten Tool (A) to the crankshaft with Tool (B). NOTICE https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 6/6(W) The front and rear seals and wear sleeves have different spiral grooves in the seal. Because of this type of design, the front seal group for an engine is different from the rear seal group. If a seal group is installed on the wrong end of the engine, oil can actually be taken out of the engine instead of moving oil back into the engine. Illustration 6 g00515623 Note: Install the seal with the arrow that shows the direction of crankshaft rotation toward the front of the engine. 4. Position wear sleeve (2) and seal (1) on Tool (A). Install Tool (D) on Tool (A). Lubricate the face of the washer on Tool (C). Install Tool (C) on Tool (A). 5. Tighten Tool (C) until Tool (D) contacts Tool (A). 6. Remove Tools (A), (B), (C), and (D). Check the crankshaft seal and the wear sleeve for the correct installation. End By: a. Install the vibration damper and the pulley. Refer to Disassembly and Assembly, "Vibration Damper and Pulley - Remove and Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 1/2(W) Product: WHEEL TRACTOR Model: 637E WHEEL TRACTOR 1FB Configuration: 637E TRACTOR / POWER SHIFT / 1FB00001-00531 (MACHINE) POWERED BY 3408 ENGINE Disassembly and Assembly 3408E and 3412E Engines for Caterpillar Built Machines Media Number -SENR1013-11 Publication Date -01/07/2015 Date Updated -22/08/2016 i01064158 Front Cover - Remove SMCS - 1166-011 Removal Procedure Start By: a. Remove the fuel filter base. Refer to Disassembly and Assembly, "Fuel Filter Base - Remove and Install". Note: The fuel filter base should be removed only if it is necessary in order to remove the front cover. Some engine arrangements do not require the removal of the fuel filter base. NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 2/2(W) Illustration 1 g00553898 Typical example 1. Remove ten bolts (1). Remove nut (3). Illustration 2 g00555863 Typical example 2. Remove nut (4) and the washer. 3. Remove cover (2) and the gasket. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 1/2(W) Product: WHEEL TRACTOR Model: 637E WHEEL TRACTOR 1FB Configuration: 637E TRACTOR / POWER SHIFT / 1FB00001-00531 (MACHINE) POWERED BY 3408 ENGINE Disassembly and Assembly 3408E and 3412E Engines for Caterpillar Built Machines Media Number -SENR1013-11 Publication Date -01/07/2015 Date Updated -22/08/2016 i01064975 Front Cover - Install SMCS - 1166-012 Installation Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Illustration 1 g00553898 Typical example 1. Clean the mating surfaces of the front housing and front cover (2). 2. Install a new gasket. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 2/2(W) 3. Install front cover (2) and secure the cover with ten bolts (1). 4. Apply 7M-7456 Compound to the threads of stud (3). Install the nut on stud (3). Illustration 2 g00555863 5. Install nut (4) and the washer. Tighten nut (4) to a torque of 35 5 N m (26 4 lb ft). End By: a. Install the fuel filter base. Refer to Disassembly and Assembly, "Fuel Filter Base - Remove and Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 1/3(W) Product: WHEEL TRACTOR Model: 637E WHEEL TRACTOR 1FB Configuration: 637E TRACTOR / POWER SHIFT / 1FB00001-00531 (MACHINE) POWERED BY 3408 ENGINE Disassembly and Assembly 3408E and 3412E Engines for Caterpillar Built Machines Media Number -SENR1013-11 Publication Date -01/07/2015 Date Updated -22/08/2016 i02160179 Gear Group (Front) - Remove SMCS - 1206-011 Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-0510 Driver Group 1 Start By: a. Remove the camshaft. Refer to Disassembly and Assembly, "Camshaft - Remove". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 2/3(W) Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. Illustration 1 g00577213 1. Align the timing mark on the idler gear with the timing mark on the crankshaft gear. 2. Remove bolts (1) and plate (2). 3. Remove idler gear (3). Illustration 2 g00577286 4. Remove the bearing from idler gear (3) with Tooling (A) and a suitable press. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 3/3(W) Illustration 3 g00577251 5. Remove thrust washer (6). Remove bolts (4) and shaft (5). Illustration 4 g00577274 6. Drilled passage (7) and drilled passage (8) in the shaft must be free of obstructions. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 1/3(W) Product: WHEEL TRACTOR Model: 637E WHEEL TRACTOR 1FB Configuration: 637E TRACTOR / POWER SHIFT / 1FB00001-00531 (MACHINE) POWERED BY 3408 ENGINE Disassembly and Assembly 3408E and 3412E Engines for Caterpillar Built Machines Media Number -SENR1013-11 Publication Date -01/07/2015 Date Updated -22/08/2016 i02151029 Gear Group (Front) - Install SMCS - 1206-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-0510 Driver Group 1 NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 2/3(W) Illustration 1 g00577251 Illustration 2 g00537659 1. Place shaft (5) in position on the cylinder block and install bolts (4). Tighten bolts (4) to a torque of 55 10 N m (41 7 lb ft). Tighten bolts (4) for the shaft in the following sequence. See Illustration 2 for the numbering of the bolts. ... 1,3,4,5,2,1,2,3,4,5,1 2. Install thrust washer (6) with the oil groove side toward the idler gear. Illustration 3 g00577286 3. Lower the temperature of the bearing. Install the bearing in idler gear (3) with Tooling (A) and a suitable press. Install the bearing to a depth of 0.38 0.25 mm (0.015 0.010 inch). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 3/3(W) Illustration 4 g00577213 4. Apply clean engine oil to the shaft and to the inside diameter of idler gear (3). Install idler gear (3) on the shaft. Install plate (2) and bolts (1). End By: a. Install the camshaft. Refer to Disassembly and Assembly, "Camshaft - Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 1/2(W) Product: WHEEL TRACTOR Model: 637E WHEEL TRACTOR 1FB Configuration: 637E TRACTOR / POWER SHIFT / 1FB00001-00531 (MACHINE) POWERED BY 3408 ENGINE Disassembly and Assembly 3408E and 3412E Engines for Caterpillar Built Machines Media Number -SENR1013-11 Publication Date -01/07/2015 Date Updated -22/08/2016 i02389879 Housing (Front) - Remove SMCS - 1151-011 Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 138-7573 Link Bracket 1 Start By: a. Remove the engine oil pan. Refer to Disassembly and Assembly, "Engine Oil Pan - Remove and Install". b. Remove the water pump. Refer to Disassembly and Assembly, "Water Pump - Remove". c. Remove the crankshaft front seal. Refer to Disassembly and Assembly, "Crankshaft Front Seal - Remove". d. Remove the front cover. Refer to Disassembly and Assembly, "Front Cover - Remove". e. Remove the speed/timing sensors. Refer to Disassembly and Assembly, "Speed/Timing Sensor - Remove and Install". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 2/2(W) Illustration 1 g00553958 1. Remove bolts (2) and retainer plate (3). 2. Remove gear (1). Illustration 2 g00553982 3. Attach Tooling (A) and a suitable lifting device to front housing (4). The weight of front housing (4) is approximately 34 kg (75 lb). 4. Remove nut (6). 5. Remove bolts (5). 6. Remove front housing (4) and the gasket. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 1/3(W) Product: WHEEL TRACTOR Model: 637E WHEEL TRACTOR 1FB Configuration: 637E TRACTOR / POWER SHIFT / 1FB00001-00531 (MACHINE) POWERED BY 3408 ENGINE Disassembly and Assembly 3408E and 3412E Engines for Caterpillar Built Machines Media Number -SENR1013-11 Publication Date -01/07/2015 Date Updated -22/08/2016 i02389888 Housing (Front) - Install SMCS - 1151-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 138-7573 Link Bracket 1 B 8T-9022 Silicone Gasket - NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 2/3(W) Illustration 1 g00553982 1. The rear of front housing (4) and the front of the cylinder block should be thoroughly cleaned before you install the front housing. 2. Install a new gasket on the cylinder block. 3. Apply Tooling (B) to the common junction of the cylinder block, the front housing and the oil pan. 4. Attach Tooling (A) and a suitable lifting device to front housing (4). The weight of front housing (4) is approximately 34 kg (75 lb). 5. Install front housing (4) on the cylinder block. 6. Install bolts (5). 7. Install nut (6). 8. Remove Tooling (A) from front housing (4). Illustration 2 g00553958 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 3/3(W) Illustration 3 g00555906 Note: With the number one piston of the engine at top center, the timing marks on the front gear group can be aligned. Align the timing marks on gear (1) with the marks on the camshaft gear. The alignment of the timing marks is shown in Illustration 3. 9. Install gear (1) and retainer plate (3). 10. Install bolts (2). Tighten the bolts to a torque of 135 20 N m (100 15 lb ft). End By: a. Install the speed/timing sensors. Refer to Disassembly and Assembly, "Speed/Timing Sensor - Remove and Install". b. Install the front cover. Refer to Disassembly and Assembly, "Front Cover - Install". c. Install the crankshaft front seal. Refer to Disassembly and Assembly, "Crankshaft Front Seal - Install". d. Install the water pump. Refer to Disassembly and Assembly, "Water Pump - Install". e. Install the engine oil pan. Refer to Disassembly and Assembly, "Engine Oil Pan - Remove and Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 1/2(W) Product: WHEEL TRACTOR Model: 637E WHEEL TRACTOR 1FB Configuration: 637E TRACTOR / POWER SHIFT / 1FB00001-00531 (MACHINE) POWERED BY 3408 ENGINE Disassembly and Assembly 3408E and 3412E Engines for Caterpillar Built Machines Media Number -SENR1013-11 Publication Date -01/07/2015 Date Updated -22/08/2016 i02389917 Valve Mechanism Cover - Remove and Install SMCS - 1107-010 Removal Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Illustration 1 g01095551 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 2/2(W) 1. Remove bolts (2). 2. Remove cover (1). Installation Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Illustration 2 g01095551 1. Install cover (1). 2. Install bolts (2). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 1/4(W) Product: WHEEL TRACTOR Model: 637E WHEEL TRACTOR 1FB Configuration: 637E TRACTOR / POWER SHIFT / 1FB00001-00531 (MACHINE) POWERED BY 3408 ENGINE Disassembly and Assembly 3408E and 3412E Engines for Caterpillar Built Machines Media Number -SENR1013-11 Publication Date -01/07/2015 Date Updated -22/08/2016 i02160475 Valve Mechanism Cover Base - Remove and Install SMCS - 1120-010 Removal Procedure Start By: a. Remove the valve mechanism cover. Refer to Disassembly and Assembly, "Valve Mechanism Cover - Remove and Install". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 2/4(W) Illustration 1 g01095563 1. Disconnect harness assembly (3). 2. Disconnect harness assemblies (5). 3. Remove bolt (4). 4. Remove bolts (1). 5. Remove base (2). Installation Procedure NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 3/4(W) Illustration 2 g01095563 1. Install base (2). 2. Install bolts (1). 3. Install bolt (4). Note: Each harness assembly has a white connector that is marked "F" (front) and a black connector that is marked "R" (rear). The white connector must be installed on the injector toward the front of the engine. The black connector must be installed on the injector toward the rear of the engine. Note: The black connector is marked "R" (rear). Assemble the black connector to the injector on the rear cylinder. The rear cylinders are 3, 7, and 11 on the left side of the engine. The rear cylinders are 4, 8, and 12 on the right side of the engine. 4. Place harness assemblies (5) on the connectors. Tighten the nuts on harness assemblies (5) to the following torque. Torque for nuts ... 1.70 0.25 N m (15.046 2.213 lb in) 5. Connect harness assembly (3). End By: a. Install the valve mechanism cover. Refer to Disassembly and Assembly, "Valve Mechanism Cover - Remove and Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

w 1/2(W) Product: WHEEL TRACTOR Model: 637E WHEEL TRACTOR 1FB Configuration: 637E TRACTOR / POWER SHIFT / 1FB00001-00531 (MACHINE) POWERED BY 3408 ENGINE Disassembly and Assembly 3408E and 3412E Engines for Caterpillar Built Machines Media Number -SENR1013-11 Publication Date -01/07/2015 Date Updated -22/08/2016 i02160605 Rocker Arm and Shaft - Remove SMCS - 1102-011 Removal Procedure Start By: a. Remove the unit injector. Refer to Disassembly and Assembly, "Unit Injector - Remove". NOTICE Keep all parts clean from contaminants. Contaminants may cause rapid wear and shortened component life. Illustration 1 g01095626 1. Remove bolt (2) and cylinder head bolt (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

w 2/2(W) 2. Remove rocker arm assembly (3) and the O-ring seal. 3. Remove the pushrods. 4. Remove valve bridges (4). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/7/28

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com