Caterpillar Cat 623H Wheel Tractor (Prefix EJD) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

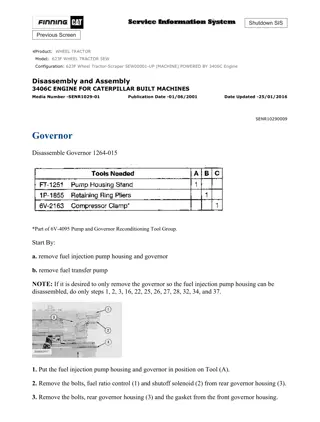

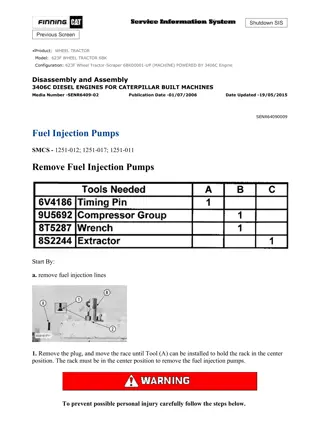

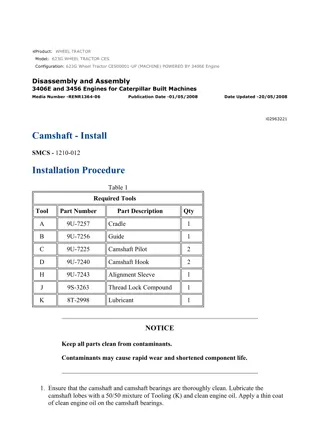

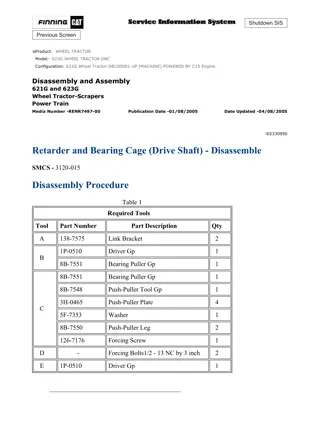

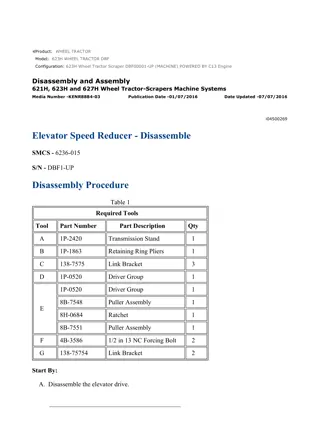

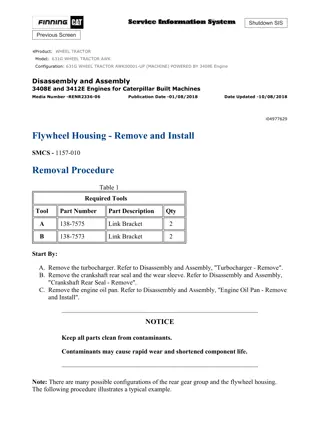

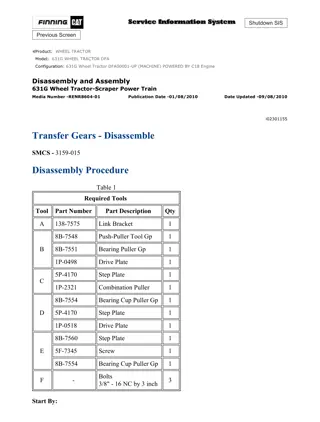

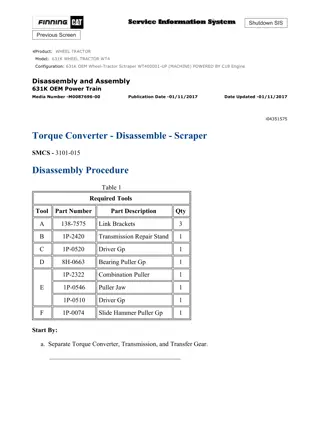

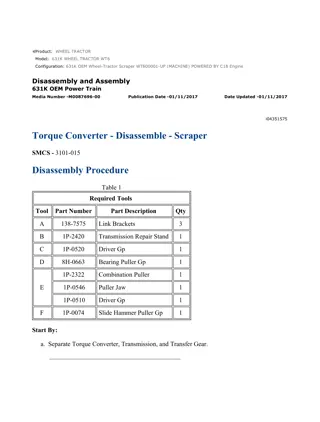

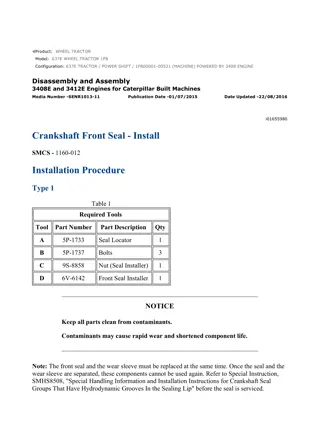

w 1/12(W) Product: WHEEL TRACTOR Model: 623H WHEEL TRACTOR EJD Configuration: 623H Wheel Tractor Scraper EJD00001-UP (MACHINE) POWERED BY C13 Engine Disassembly and Assembly 621H, 623H and 627H Wheel Tractor-Scrapers Machine Systems Media Number -KENR9489-02 Publication Date -01/07/2016 Date Updated -07/07/2016 i04500269 Elevator Speed Reducer - Disassemble SMCS - 6236-015 S/N - EJD1-UP Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-2420 Transmission Stand 1 B 1P-1863 Retaining Ring Pliers 1 C 138-7575 Link Bracket 3 D 1P-0520 Driver Group 1 1P-0520 Driver Group 1 8B-7548 Puller Assembly 1 E 8H-0684 Ratchet 1 8B-7551 Puller Assembly 1 F 4B-3586 1/2 in 13 NC Forcing Bolt 2 G 138-75754 Link Bracket 2 Start By: A. Disassemble the elevator drive. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 2/12(W) Illustration 1 g00496940 1. Attach the elevator speed reducer to Tooling (A), as shown. Place an alignment mark on the speed reducer for assembly purposes. Illustration 2 g01079336 2. Use Tooling (B) to remove retaining ring (1) from flywheel housing (2). Remove bolts (3) from flywheel housing (2) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 3/12(W) Illustration 3 g01079337 3. Attach Tooling (G) and a suitable lifting device onto flywheel housing (2). Use Tooling (F) to loosen flywheel housing (2) from end plate (4). Remove flywheel housing (2) from end plate (4). The weight of flywheel housing (2) is approximately 32 kg (71 lb). Illustration 4 g01079658 4. Use Tooling (D) and a suitable press to remove roller bearing (5) (not shown) and lip seal (6) (not shown) from flywheel housing (2) . Illustration 5 g00800103 5. Attach Tooling (C) and a suitable lifting device onto flywheel (7). Remove flywheel (7) from end plate (4). The weight of flywheel (7) is approximately 12 kg (26 lb). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

w 4/12(W) Illustration 6 g01079338 6. Remove retaining ring (8) and thrust disc (9) from hub (10) . Illustration 7 g00800112 7. Use Tooling (E) to remove bearing inner race (11) from hub (10). Repeat the procedure for the other side of hub (10) . Illustration 8 g01079339 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 5/12(W) 8. Drive pin (13) into gear (12). Remove gear (12) from hub (10). Remove pin (13) from gear (12). Bend the locking tabs away from bolts (14). Remove bolts (14) and the locking tabs from flywheel (7). Remove hub (10) from flywheel (7) . Illustration 9 g00848811 9. Attach Tooling (C) and a suitable lifting device onto end plate (4). Remove end plate (4) from the ring gear. The weight of end plate (4) is approximately 19 kg (42 lb). Illustration 10 g01079340 10. Remove O-ring seal (17) from end plate (4). Use Tooling (D) and a suitable press to remove roller bearing (15) (not shown) and lip seal (16) (not shown) from end plate (4) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 6/12(W) Illustration 11 g00848814 11. Attach Tooling (C) and a suitable lifting device onto carrier assembly (18). Remove carrier assembly (18) from the ring gear. The weight of carrier assembly (18) is approximately 30 kg (66 lb). Illustration 12 g01079341 12. Drive spring pin (20) into shaft (19). Remove shaft (19) from carrier assembly (18). Remove spring pin (20) from shaft (19). Remove gear (21) from carrier assembly (18). Repeat the procedure for the other two gears. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 7/12(W) Illustration 13 g01079342 13. Remove washers (23) and bearing (22) from gear (21). Repeat the procedure for the other two gears. Illustration 14 g01079343 14. Remove retaining ring (24) and sun gear (25) from the carrier assembly. Illustration 15 g00848818 15. Attach Tooling (C) and a suitable lifting device onto carrier assembly (26). Remove carrier assembly (26) from the ring gear. The weight of carrier assembly (26) is approximately 62 kg (137 lb). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 8/12(W) Illustration 16 g00800168 16. Drive spring pin (27) into shaft (28). Remove shaft (28) and gear (29) from the carrier assembly. Remove spring pin (27) from shaft (28). Repeat the procedure for the other two gears. Illustration 17 g01079347 17. Remove washers (32), bearings (30), and spacer (31) from gear (29). Repeat the procedure for the other two gears. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 9/12(W) Illustration 18 g01079350 18. Remove retaining ring (33), thrust washer (34), and sun gear (35) from the carrier assembly. Illustration 19 g01079352 19. Attach Tooling (C) and a suitable lifting device onto ring gear (36). Remove bolts (37) from ring gear (36). Remove ring gear (36) from housing (38). The weight of ring gear (36) is approximately 65 kg (143 lb). Illustration 20 g01079353 20. Remove spring pins (39) that lock bolts (40) into retainer plate (41). Remove bolts (40), retainer plate (41), and the shims from the housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 10/12(W) Illustration 21 g01087791 21. Attach Tooling (G) and a suitable lifting device onto housing (38). Remove housing (38) from plate (42) . Illustration 22 g00800186 22. Turn over housing (38). Remove Duo-Cone seal (43) from housing (38). Use Tooling (D) and a suitable press to remove coupling gear (44) from housing (38) . Illustration 23 g00800188 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 11/12(W) 23. Remove bearing cone (45) from coupling gear (44). Use a hammer and punch through Holes (X) in order to remove the bearing from the coupling gear. Illustration 24 g00800190 24. Remove bolts (46) from plate (47). Remove plate (47) from the housing. Illustration 25 g00800191 25. Use Tooling (D) and a suitable press to remove bearing cone (48) (not shown) and bearing cup (49) (not shown) from housing (38) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 12/12(W) Illustration 26 g00800194 26. Remove Duo-Cone seal (50) from plate (42). Remove spacer (51) from plate (42) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

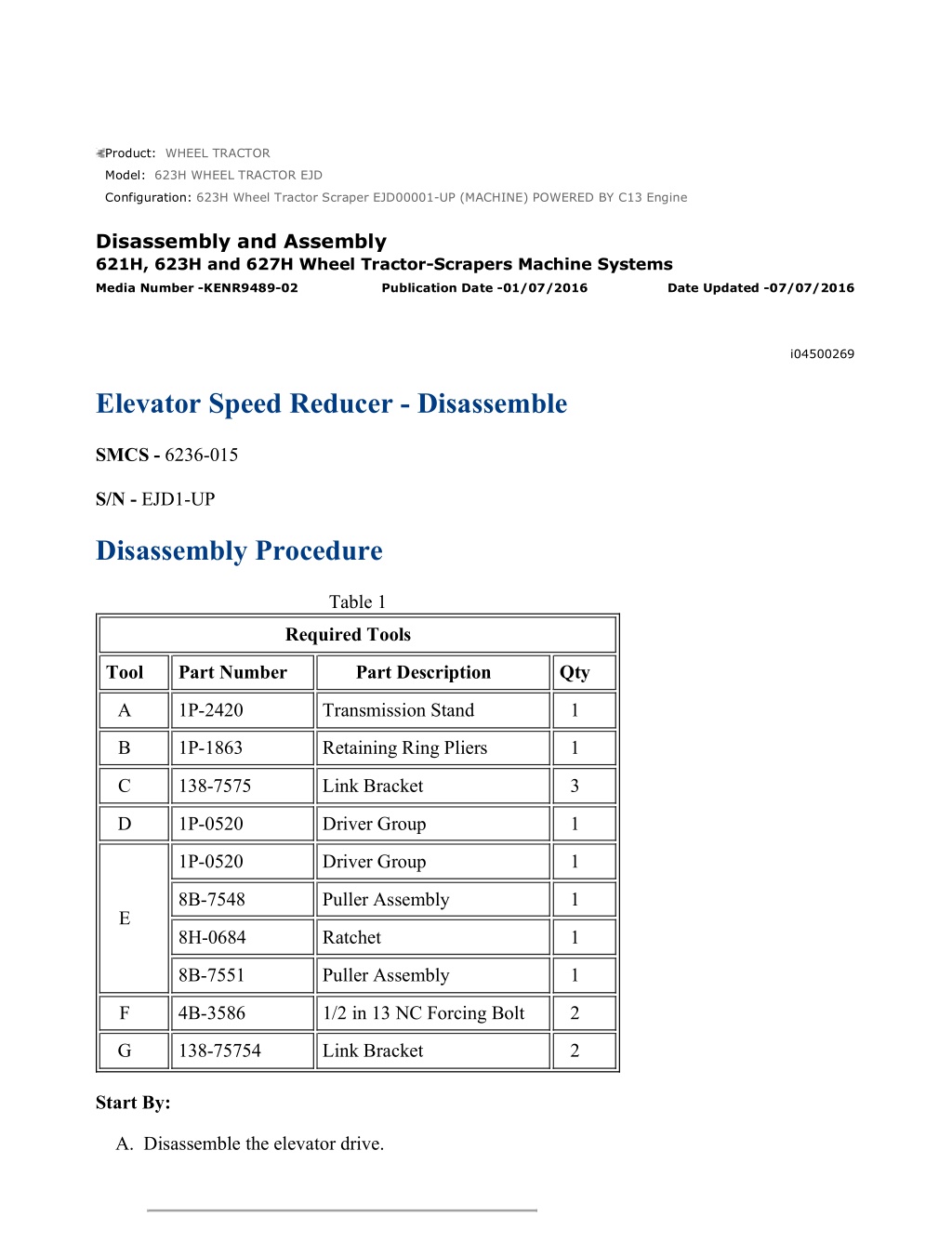

w 1/11(W) Product: WHEEL TRACTOR Model: 623H WHEEL TRACTOR EJD Configuration: 623H Wheel Tractor Scraper EJD00001-UP (MACHINE) POWERED BY C13 Engine Disassembly and Assembly 621H, 623H and 627H Wheel Tractor-Scrapers Machine Systems Media Number -KENR9489-02 Publication Date -01/07/2016 Date Updated -07/07/2016 i06642617 Elevator Speed Reducer - Disassemble SMCS - 6236-015 S/N - EJD1-UP Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 439-3940 Bracket As 2 B 154-6181 Forcing Bolt 2 C - Eyebolt 2 D 4C-8358 Eyebolt 2 E - Eyebolt 2 F 421-5664 Eyebolt 2 G - Eyebolt 2 H 1P-0520 Driver Group 1 Start By: a. Disassemble the elevator drive. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 2/11(W) Illustration 1 g06065916 1. Place the elevator speed reducer on a suitable stand. Place an alignment mark on the speed reducer for assembly purposes. Illustration 2 g06065918 2. Remove bolts (1) from cover (2). Illustration 3 g06068264 3. Attach Tooling (A) and a suitable lifting device onto cover (2). Use Tooling (B) to loosen cover (2) from cover assembly (3). The weight of cover (2) is approximately 16 kg (36 lb). Remove cover (2) from cover assembly (3). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 3/11(W) Illustration 4 g06065921 4. Remove rings (4) and seal (5) from cover (2). Illustration 5 g06065923 5. Use Tooling (H) and a suitable press to remove bearing (6) from cover (2). Remove bearing (6). Illustration 6 g06065927 6. Remove O-ring seal (7) and cotter pin (8). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 4/11(W) Illustration 7 g06065928 7. Use Tooling (C) and a suitable lifting device to remove flywheel (9). The weight of flywheel (9) is approximately 24 kg (53 lb). Remove flywheel (9). Illustration 8 g06065931 8. Remove sleeves (10) from flywheel (9). Illustration 9 g06065932 9. Remove bolts (11). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 5/11(W) Illustration 10 g06065937 10. Use Tooling (D) and a suitable lifting device to remove cover (12). The weight of cover (12) is approximately 50 kg (111 lb). Remove cover (12). Illustration 11 g06065939 11. Remove rings (13) and seal (14) from cover (12). Illustration 12 g06065940 12. Use Tooling (H) and a suitable press to remove bearing (15) from cover (12). Remove bearing (15). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 6/11(W) Illustration 13 g06065943 13. Remove gear shaft (16). Illustration 14 g06065944 14. Remove retaining ring (17) and planetary gear (18). Illustration 15 g06065946 15. Remove retaining rings (19) and bearing (20) from planetary gear (18). 16. Repeat Step 14 and Step 15 to remove the remaining planetary gears (18). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 7/11(W) Illustration 16 g06065948 17. Remove retaining ring (21) and planetary carrier (22). Illustration 17 g06065950 18. Remove gear shaft (23). Illustration 18 g06066892 19. Remove bolts (24). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 8/11(W) Illustration 19 g06065954 20. Use Tooling (E) and a suitable lifting device to remove carrier assembly (25). The weight of carrier assembly (25) is approximately 104 kg (230 lb). Remove carrier assembly (25). Illustration 20 g06065957 21. Remove bolts (27) and carrier (26). Illustration 21 g06066925 22. Remove washers (29), gear (30), and bearing (31) from flange (28). 23. Repeat Step 22 to remove the remaining washers (29), gears (30), and bearings (31). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 9/11(W) Illustration 22 g06066982 24. Remove flange (32) from flange (28). Illustration 23 g06065966 25. Remove spring pin (33). 26. Use Tooling (F) and a suitable lifting device to remove gear (34). The weight of gear (34) is approximately 39 kg (86 lb). Remove gear (34). Illustration 24 g06065970 27. Remove spring pin (33) and O-ring seal (35). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 10/11(W) Illustration 25 g06065973 28. Use Tooling (G) and a suitable lifting device to remove cover (36). The weight of cover (36) is approximately 82 kg (181 lb). Remove cover (36). Illustration 26 g06065974 29. Remove bearings (37) from cover (36). Illustration 27 g06065976 30. Remove pad (38) and seal (39) from flange (40). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

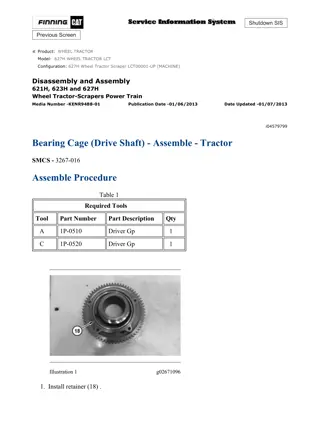

w 1/12(W) Product: WHEEL TRACTOR Model: 623H WHEEL TRACTOR EJD Configuration: 623H Wheel Tractor Scraper EJD00001-UP (MACHINE) POWERED BY C13 Engine Disassembly and Assembly 621H, 623H and 627H Wheel Tractor-Scrapers Machine Systems Media Number -KENR9489-02 Publication Date -01/07/2016 Date Updated -07/07/2016 i04500289 Elevator Speed Reducer - Assemble SMCS - 6236-016 S/N - EJD1-UP Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-2420 Transmission Stand 1 B 1P-1863 Retaining Ring Pliers 1 C 138-7575 Link Bracket 3 D 1P-0520 Driver Group 1 G 138-7574 Link Bracket 2 NOTICE Keep all parts clean from contaminants. Contamination of the hydraulic system with foreign material will reduce the service life of the hydraulic system components. To prevent contaminants from entering the hydraulic system, always plug or cap the lines, fittings, or hoses as they are disconnected. Cover any disassembled components and clean them properly before assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 2/12(W) Clean the hydraulic system properly after any major component exchange or especially after a component failure, to remove any contamination. 1. Clean all parts and inspect all parts. If any parts are worn or damaged, use new parts for replacement. Illustration 1 g00800270 2. Make sure that the plate is securely placed on Tooling (A). Install spacer (51) to plate (42). Install Duo-Cone seal (50) to plate (42) . Illustration 2 g00800271 3. Lower the temperature of bearing cup (49). Install bearing cup (49) into housing (38) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 3/12(W) Illustration 3 g00800269 4. Position plate (47). Install bolts (46) into plate (47). Tighten bolts (46) to a torque of 55 10 N m (41 7 lb ft). Illustration 4 g00800272 5. Raise the temperature of bearing cone (45). Install bearing cone (45) onto coupling gear (44) . Illustration 5 g01079903 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

w 4/12(W) 6. Attach Tooling (G) and a suitable lifting device onto housing (38). Install housing (38) onto coupling gear (44) . Illustration 6 g00800274 7. Raise the temperature of bearing cone (48) (not shown). Install bearing cone (48) (not shown) into coupling gear (44) (not shown). Install Duo-Cone seal (43) . Illustration 7 g01087791 8. Attach Tooling (G) and a suitable lifting device onto housing (38). Install housing (38) onto plate (42) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

w 5/12(W) Illustration 8 g01079353 Note: Do not use an impact wrench to install bolts (40) . 9. Place three pieces of Plastigage on the retainer plate for assembly purposes. Install retainer plate (41), the Plastigage, and bolts (40) onto the housing. Tighten bolts (40) to a torque of 150 20 N m (111 15 lb ft). Remove retainer plate (41), the Plastigage, and bolts (40) from the housing. Note: Place the thinner shims between the thicker shims during installation. 10. Find the average measurement of the Plastigage. Select the quantity of shims equal to the measurement of the Plastigage minus 0.03 0.08 mm (0.0012 0.0031 inch). Install retainer plate (41), the shims, and bolts (40). Tighten bolts (40) to a torque of 150 20 N m (111 15 lb ft). If necessary, additionally tighten bolts (40) until spring pins (39) can be installed into retainer plate (41) . Illustration 9 g01079352 11. Attach Tooling (B) and a suitable lifting device onto ring gear (36). Install ring gear (36) onto housing (38). The weight of ring gear (36) is approximately 65 kg (143 lb). Install bolts (37) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2021/4/7

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com