Bio-Economic Projects in Zealand, Denmark: Enhancing Sustainable Biomass Utilization

Dr. Rikke Lybk from the University of Roskilde in Denmark presents bio-economic projects focusing on utilizing biomass resources like straw, sludge, wood, and sugar beet residues in Zealand. The methodology involves leveraging existing technology, circular economy principles, and new pathways to create bio-based products and services. Examples include a Straw-Processing-Station for bio-energy and natural fiber plastic composites. The challenges in bio-refinery projects and the potential for new low-cost pathways are also discussed.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

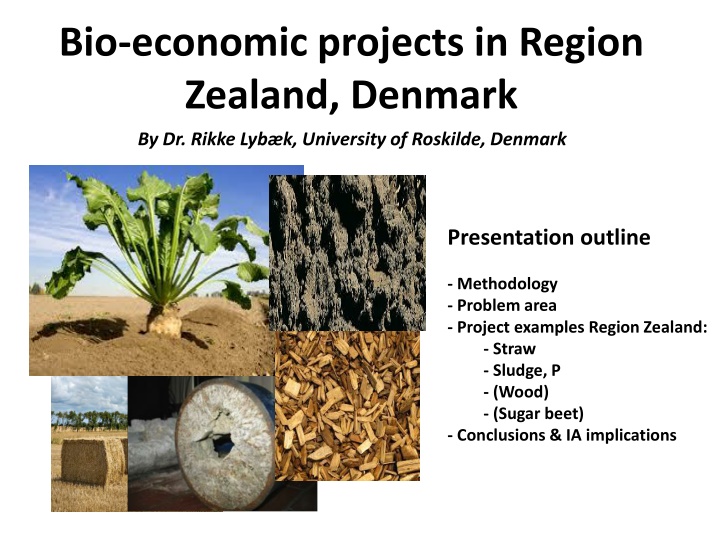

Bio-economic projects in Region Zealand, Denmark By Dr. Rikke Lyb k, University of Roskilde, Denmark Presentation outline - Methodology - Problem area - Project examples Region Zealand: - Straw - Sludge, P - (Wood) - (Sugar beet) - Conclusions & IA implications

Methodology Research Question: - Which bio-economic projects can beneficially be implemented in Region Zealand, when looking at the available biomass resources and existing and reliable technical solutions? Our understanding of biomass to utilize: - Focus on biomass residues & existing crops in new ways of production, and for completely new products and services, etc. Available local biomass residues: - Within Region Zealand the following biomass resources are available; Straw, sludge, wood and sugar beet residues. (as opposed to crops being food & import of biomass). Deploy existing and reliable technology: - Start utilize existing and well-functioning biomass tech. adapted to the bio-economic context to commence a transition towards the use of renewable resources, then - Parallel research & demonstration in more advanced & costly bio-refinery technology with long realization timeframe, and unsure economic profit. Approaches in adapting bio-economic solutions: - Circular Economy, Cascading of materials & energy, Resource Efficiency.

Problem area Bio-refinery Existing bio-economic projects (drop-in strategy): - Normally entails deployment of very advanced and costly bio-refineries with little success Scandinavia (Maabjerg Plant & Sk ne Plant) = Downgraded to demo plants or closed down! - Refinery made building blocks (e.g. C5+C6 sugars, syngas, oil, fiber) are used in an existing fossil chain. - Building blocks used for: fuel, chemicals, fodder & high value products e.g. pharma-additives, aroma etc. - Process require costly enzymes & steam at high pressure and temperature etc. New bio-economic projects (new pathway): - We will identify new low-cost pathways with focus on a bio-based non-fossil fuel value chain, that - Utilizes the inherent & easily accessible qualities of biomass for new products, e.g. lignin in straw (strong).

Project examples Region Zealand Straw: Resource: - 300,000 tons of cereal straw residues are available in Region Zealand (of a total of 2,500,00 tons in DK). The project: - Straw-Processing-Station can provide different types of bio-energy, and low cost - Fractions of Natural Fiber Plastic Composite (NFPC) be mechanically processed (e.g. grinded). - The energy & NFPC substitute fossil fuels & new bio-products and services are produced, e.g. - NFPC-fences and teresse-flooring (stronger, lighter., harder products due to lignin in straw). - All RE energy services are based on well-proven biogas & combustion technologies.

Sludge: Resources: - Sludge generated in Region Zealand account for 3,400,000 tons, hereof 680 tons P (a mineral). - Most of it lost to the aquatic's, or incinerated in waste incineration plants, or - Not accessible for plants in the soil when distributed as sludge on the farm land. - 80 % of the phosphor must now be re-cycled in DK before 2020 & Org. waste separated =biogas! - Today, re-use of P from sludge (117 t. P), animal manure (263 t. P) & artificial supply (240 t. P). The project: - Collect P from waste-water on waste-water treatment plants in the Region Zealand, by - A reactor with magnesium-salt that catches the P & nitrogen as struvite (60-90 t.), and will - Substitute 25-40 % P from artificial fertilizer (180-150 t.) requiring much fossil energy to produce, - Based on well-known technology & re-cycle a finite resource (P) & save fossil fuels.

Conclusion & IA implications Utilize existing and available local biomass residues for different bio-economic projects. Look at already proven and reliable technology, and then parallel seek to develop more advanced bio-refinery tech. for the future separating biomass into building blocks. Existing Drop-in strategy rely on expensive & un-mature high-tech. refineries, with little success in Denmark and Scandinavia. The New pathway will avoid a fossil fuel value chain and make bio-based products and services, deploying mature & well-known technology. Can be implemented today based on existing & available biomass residues, and will Generate new job opportunities and income in rural areas in DK lacking development. We ll see immediate environmental & economic impacts from such bio-economic projects.