Antiviral Thin Films for Respiratory Protection

Simulation of antiviral thin films for face masks to enhance respiratory protection. Investigate breathability and airflow through the mask using Computer Aided Design and Computational Fluid Dynamics.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

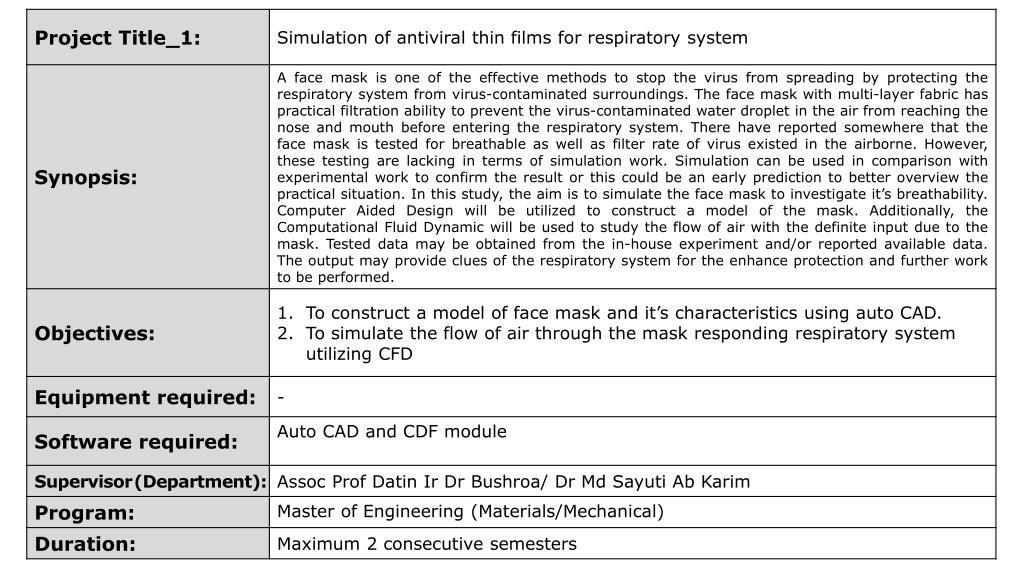

Project Title_1: Simulation of antiviral thin films for respiratory system A face mask is one of the effective methods to stop the virus from spreading by protecting the respiratory system from virus-contaminated surroundings. The face mask with multi-layer fabric has practical filtration ability to prevent the virus-contaminated water droplet in the air from reaching the nose and mouth before entering the respiratory system. There have reported somewhere that the face mask is tested for breathable as well as filter rate of virus existed in the airborne. However, these testing are lacking in terms of simulation work. Simulation can be used in comparison with experimental work to confirm the result or this could be an early prediction to better overview the practical situation. In this study, the aim is to simulate the face mask to investigate it s breathability. Computer Aided Design will be utilized to construct a model of the mask. Additionally, the Computational Fluid Dynamic will be used to study the flow of air with the definite input due to the mask. Tested data may be obtained from the in-house experiment and/or reported available data. The output may provide clues of the respiratory system for the enhance protection and further work to be performed. Synopsis: 1. To construct a model of face mask and it s characteristics using auto CAD. 2. To simulate the flow of air through the mask responding respiratory system utilizing CFD Objectives: Equipment required: - Auto CAD and CDF module Software required: Supervisor(Department): Assoc Prof Datin Ir Dr Bushroa/ Dr Md Sayuti Ab Karim Program: Master of Engineering (Materials/Mechanical) Duration: Maximum 2 consecutive semesters

Development of antibacterial bioglass (BG) incorporated coating on Ti alloy substrate via Plasma Electrolytic Oxidation Method Project Title_2: Ti alloy is the commonly used metallic substrate as a medical implant. However, the poor bioactivity characteristics possessed by this alloy may hinder the inducement of apatite layer at tissue/bone and implant interface. Thus, depositing a biocompatible coating on the alloy can provide solution to this current limitation. Meanwhile, BG is a bioactive material that is capable of improving the interaction of the implant materials with surrounding body fluid and inducing the formation of an apatite layer at the bone/implant interface. Previous work of incorporating the BG particles into the plasma electrolytic oxidation (PEO) coating has been successfully demonstrated. Thus, this achievement motivates for a further research exploration by incorporating Ag and GO particles to promotes the antibacterial properties. The structural characteristics of the coating will be evaluated by utilizing X-ray diffraction (XRD), field emission scanning electron microscopy (FESEM), and energy dispersive X-ray spectroscopy (EDAX). The mechanical and bioactivity properties will be evaluated by the Vickers hardness, micro scratch, and simulated body fluid (SBF) testing respectively. By the end of this research, it is expected that the the coating layer demonstrate sufficient strength and bioactive properties. Synopsis: 1. To deposit bioglass based coating incorporated with Ag and GO. 2. To perform the properties of the deposited layer. Objectives: Equipment required: PEO, XRD, FESEM, EDX, SBF Software required: - Supervisor(Department): Assoc Prof Datin Ir Dr Bushroa Program: Master of Engineering (Materials/Mechanical) Duration: Maximum 2 consecutive semesters

Project Title_3: Towards machine learning in predicting the performance of hardness of the bioglass coatings Selected type of bioglass based coatings will be identified. Data that is already collected will be utilized in this study. Previous lab experiments have never been attempted to determine the correlation between the experimental and the predicted one in the deposited bioglass. So, this project will investigate the correlation of the data; suggest and justify the best parameters for fabrication of the bioglass coating in order to get sufficient and relevant hardness. This project will utilize the software such as Suppress Vector Regression Model. Phyton programming language in the MATLAB could also be used as comparison. Synopsis: 1. To optimize the hardness of the bioglass coating 2. To compare methods in the optimization technique dedicated for deposited coatings Objectives: Equipment required: - Software required: MATLAB, Phython programming language Supervisor(Department): Assoc Prof Datin Ir Dr Bushroa Program: Master of Engineering (Materials/Mechanical) Duration: Maximum 2 consecutive semesters

Utilizing magnet for improving efficiency of deposited layer in Plasma Electrolytic Oxidation (PEO) technique Project Title_4: PEO is a technique of depositing a slightly thin layer (depending on time of deposition). It is attractive since it used a high plasma during the deposition process and thus compromise the high intact of deposited layer onto its substrate. In the meantime, there is a new research topic in regards of using a magnet place in the vicinity of the experimental set up of electrolysis method. The magnet is claimed to enhance the splitting of electrolyte components. This will increase the efficiency of the oxidation and reduction in this type of deposition technique. The use of magnet motivates the research to explore its influence not only enhancing the process but also possible alignment of the crystal growth. Since this is relatively new research, literature review will be conducted. Concept of fabrication will be explored. Model of the concept will be the expected output. Synopsis: 1. To fabricate coating using PEO in the presence of magnet 2. To determine concept of model in fabricating the deposit layer Objectives: Equipment required: PEO, optical microscope, FESEM Software required: Auto CAD Supervisor(Department): Assoc Prof Datin Ir Dr Bushroa Program: Master of Engineering (Materials/Mechanical) Duration: Maximum 2 consecutive semesters