Comprehensive Guide to OSHA Respiratory Protection Training Program

Explore the OSHA requirements outlined in Part 1910.134 for respiratory protection training. Learn how to establish an OSHA-compliant program, differentiate between masks and respirators, and understand the functionalities and limitations of respirators. Discover the employer obligations in implementing a respiratory protection program, including hazard evaluation, respirator selection, and program administration.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

N95 Respiratory N95 Respiratory Protection Training Protection Training Updated 8/11/2020

Training Objectives Understand the requirements of OSHA 29 CFR Part 1910.134 Learn how to set up and administer an OSHA-compliant respiratory protection program Recognize the differences between masks and respirators Understand how respirators work - their capabilities & limitations 2 8/11/2020

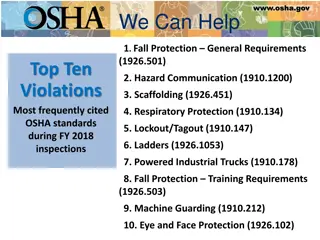

OSHA 29 CFR Part 1910 (Subpart I) Personal Protective Equipment Employers must assess the workplace to determine if hazards are present, or are likely to be present, which necessitate the use of personal protective equipment (PPE). 1910.132 General requirements. 1910.133 Eye and face protection. 1910.134 Respiratory protection. 1910.135 Head protection. 1910.136 Foot protection. 1910.137 Electrical protective devices. 1910.138 Hand Protection. + 3 8/11/2020

OSHA 29 CFR Part 1910.134 Respiratory Protection Standard (a) Permissible practice (b) Definitions (c) Respirator program (d) Selection of respirators (e) Medical evaluation (f) Fit testing (g) Use of respirators (h) Maintenance and care (i) Breathing air quality and use (j) Identification of filters, cartridges, and canisters (k) Training and information (l) Program evaluation (m) Recordkeeping (n) Dates (o) Appendices (mandatory) A: Fit Testing Procedures B-1: User Seal Checks B-2: Cleaning Procedures C: Medical Questionnaire D: Information for Employees Wearing Respirators When Not Required Under the Standard 4 8/11/2020

OSHA Respiratory Protection Program Employer Requirements Identify & evaluate respiratory hazards in the workplace Select and provide appropriate respirator based on these respiratory hazards Designate a program administrator qualified by appropriate training or experience to administer the respiratory protection program conducts the required evaluations of program effectiveness Develop & implement a written respiratory protection program + 5 8/11/2020

6 8/11/2020

Required Elements of the Written Program Procedures for selecting respirators Medical evaluations of employees required to use respirators Fit testing procedures for tight-fitting respirators such as an N95 Procedures for proper use of respirators in routine & emergency situations Procedures and schedules for cleaning, disinfecting, storing, inspecting, repairing, discarding, and maintaining respirators* 7 8/11/2020

Required Elements of the Written Program (cont.) Training of employees in respiratory hazards to which they are potentially exposed during routine and emergency situations Training of employees in proper use of respirators, including donning and doffing, any limitations on their use, and their maintenance Procedures for regularly evaluating the effectiveness of the program 8 8/11/2020

Medical Aspects of Respirator Use Must complete medical evaluation prior to initial fit-testing and any useon the job Must use OSHA questionnaire or medical examination that obtains the same information Questionnaires and medical examinations are confidential and protected by HIPAA Not permitted to wear a respirator until medical clearance form signed + 9 8/11/2020

Medical Aspects of Respirator Use (cont.) Annual medical evaluations not required Reevaluation may be needed, if employee reports medical signs or symptoms related to ability to use a respirator supervisor or respirator program administrator reports need for reevaluation observations made during fit testing and program evaluation indicate need for employee reevaluation changes occur in workplace that may result in a substantial increase in physiological burden 10 8/11/2020

OSHA Respiratory Protection Program Training Requirements No employee will be permitted to work with a respirator until trained in respiratory protection Must cover the following topics annually: General requirements of appropriate federal & state respiratory protection standards Potential work-related respiratory hazards and risks associated with not using and maintaining respirator properly Function, capabilities, limitations of selected respiratory protection How to inspect, don and remove, check seals, and wear the respirator properly Medical symptoms/signs that might limit/prevent effective use of respirators + 11 8/11/2020

DIRECTIVE NUMBER: DIR 2021-02 (CPL 02) EFFECTIVE DATE: 06-28-2021 SUBJECT: Inspection Procedures for the COVID-19 Emergency Temporary Standard 12 12/02/2021

OSHA Can Cite Employers for Failure to: Provide affected employees who provide and use their own respirators with the notice Provide training to ensure that each employee wearing a respirator receives training prior to first use and if they change the type of respirator Ensure employees are conducting user seal checks Supervise reuse of respirators Require employees to discontinue use of respirators when employees report or experience signs and symptoms that are related to their ability to use a respirator 13 12/02/2021

Facemasks Loose-fitting - don't provide complete protection Create physical barrier between mouth and nose of wearer and potential contaminants Help reduce exposure of wearer s saliva and respiratory secretions to others Help block large-particle droplets, splashes, sprays or splatter that may contain viruses and bacteria Do not filter very small particles transmitted by coughs, sneezes or certain medical procedures 14 8/11/2020

Air-Purifying Respirator (APR) Tight-fitting respirator with a filter, cartridge, or canister that removes specific air contaminants by passing ambient air through the air-purifying element. 15 8/11/2020

Types of Air Purifying Respirators Particulate Respirators Gas & Vapor Respirators Combination Respirators 16 8/11/2020

Examples of Air Purifying Respirators 17 8/11/2020

Particulate, Filtering Facepiece Respirators (Dust Masks) Negative pressure, particulate, air purifying respirator with a filter as an integral part of the facepiece or with the entire facepiece composed of the filtering medium. N95 commonly used in healthcare settings as part of airborne precautions Protects against infectious aerosols 18 8/11/2020

Particulate Filtering Facepiece Classification Resistances Efficiencies N100 (99.97% efficient or HEPA) N = Not Oil Resistant N95 N99 (95% efficient) (99% efficient) R = Oil Resistant R95 R99 R100 P = Oil Proof P95 P99 P100 19 8/11/2020

Particle Filtration Involves 4 Mechanisms: Interception, Inertial Impact, Diffusion, and Electrostatic Charge Mid-size particles captured between respirator fibers. Airstream Fiber Particle Fiber 20 8/11/2020

Particle Filtration Involves 4 Mechanisms: Interception, Inertial Impact, Diffusion, and Electrostatic Charge Large particle inertia causes it to leave airstream and impact respirator fiber. Airstreams Fiber Particle Fiber 21 8/11/2020

Particle Filtration Involves 4 Mechanisms: Interception, Inertial Impact, Diffusion, and Electrostatic Charge Very small particles affected by Brownian motion as opposed to airstream; random motion due to molecular bombardment Airstreams Fiber Particle Fiber 22 8/11/2020

Particle Filtration Involves 4 Mechanisms: Interception, Inertial Impact, Diffusion, and Electrostatic Charge Respirator carries an electrostatic charge which attracts particles. Airstreams Fiber Fiber Particle 23 8/11/2020

Why is 0.3m Targeted? Overall Efficiency Increasing Efficiency Diffusion Interception Impaction medium & large particles 0.1 m 0.3 m 1.0 m 10 m very small particles larger particles Particle Diameter ( m) 8/11/2020 24

N95 Respirator Rating 95% Filter Efficiency vs Various Particle Size Distributions Higher Efficiency 100 99 98 Virus (0.02 - 0.25 m) % Efficiency Bacterium (0.2 - 2 m) 97 96 95 0.3 m 94 0.01 0.1 1 10 Particle Size m (MMAD) 25 8/11/2020

Loose Fitting Powered Air Purifying Respirator (PAPR) May need PAPR if have facial hair or cannot pass a fit test No fit testing needed Average Cost > $1,000 26 8/11/2020