Magnetic Measurements and Dipoles: Preparation Meeting Overview

In the preparation meeting for Magnetic Measurements at CERN, GSI, and CEA, various aspects of dipoles and measurement systems were discussed. Topics included instrument configuration, cycling requirements, accuracy considerations, and practical aspects such as reproducibility. The meeting outlined the total days required for different processes and detailed the parameters and calibration needed for accurate measurements. The discussions also covered the integral field accuracy, homogeneity requirements, measurement paths, and report documentation.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Magnetic Measurements WP CERN GSI/CEA MM preparation meeting, 12.06.2015.

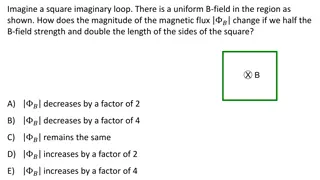

Dipoles Translating coils B ( ) V t l B B 1 A = + ( ) ( ) ( ) B d dl t dt B A s c ( ) A A t A The flux measured from the absolute coil is the convolution of the field profile and a rectangular function. The integral over f*g is equal to the product of the integrals f and g CERN GSI/CEA MM preparation meeting, 12.06.2015. 2

Dipoles Total number of dipoles: 24 Measurement system - Translating fluxmeter with 12 coils - Speed min 0.1 m/s - Magnet ramp rate 120 sec from 0 to Imax - Eddy current stabilization time 60 sec (to be verified on the pre-series) - Support tables installed and aligned during the cool down - 3 vertical levels - 5 current plateaus CERN GSI/CEA MM preparation meeting, 12.06.2015. 3

Dipoles Parameter Requirements Time Instrument configuration and check 1 day Pre-cycling 3 pre-cycles (480 sec min duration each) total ~0.13 days Cycling (5 plateaus from Imin to Imax) 0.08 days (times 3 vertical levels) Displacement next vertical level 0.12 days (times 3 vertical levels) Measurement time (Series tests) Next measurement cycling configuration 0.03 days (times 3 vertical levels) Data analysis 1.5 days (to be done at cold in case measurements should be repeated) Relative calibration (1 times per month) in the magnet under test 2 days Absolute calibration (1 per month?) in the magnet under test 2 days Total 8 days 10 days CERN GSI/CEA MM preparation meeting, 12.06.2015. 4

Dipoles 3 longitudinal parts Absolute integral field required accuracy + 5*10-4 Field Quality Integral field homogeneity required accuracy + 5*10-5 + Definitions: ( , ) ) 0 , 0 ( L B B x y = d ) , = ( B B I ( , ) L B x y L Homogeneity definition (should the gradient be considered in here)? - L n ) 0 , 0 ( L B Measurement path in the longitudinal direction (hard edge or parabolic path?) - Path length (4000 mm) can it be reduced for series tests (provided that the full map will give the information about the whole fringe field) - Measurement report (passport with checklist ok/not ok, database with field homogeneity, etc.) - The BL reference value? - Measurement of B0 - How the measured field homogeneity will be treated? - Polarity convention of homogeneity measurements due to the different configurations of the measurement benches - CERN GSI/CEA MM preparation meeting, 12.06.2015. 5

Dipoles 3 longitudinal parts Absolute integral field required accuracy + 5*10-4 Field Quality Integral field homogeneity required accuracy + 5*10-5 Practical aspects: M2M reproducibility: measurement hall not thermally stabilized, is it enough to provide measurements of the yoke temperature? - Is it foreseen to have an hall probe (or any other monitor sensor) during the magnet operation? - Position of fiducials: How are the fiducials related w.r.t. the pole surface (mechanical measurement, absolute positioning w.r.t. lamination?) and who will provide these measurements - Tolerances on the cryostat installation? (access to the pole surface) - CERN GSI/CEA MM preparation meeting, 12.06.2015. 6

Dipoles Extended measurement program for the pre-series Full map with 3D hall probe at 3 currents and 3 planes of: One dipole unit per type (2 + 1) - All dipoles with (straight) exit for beam (2 +[1]) - Yoke assembly reproducibility test - Open questions: Is it not foreseen to test the variation of a local measurement w.r.t. the integral measurement? - Is the measurement platform foreseen to have access to the straight section of the magnet? - Is it possible to dismount half yoke of the magnet in the build. 180 and reassembly it ? - Total scan length? - Is it foreseen to shim to adjust the magnetic length or the homogeneity of the pre-series magnet ? - CERN GSI/CEA MM preparation meeting, 12.06.2015. 7

Multiplets Series test requirements Parameters Requirements Length of the measurements path 2320 mm (short quads) 2720 mm (long quads) Aperture radius (mm) 190 Good Field region radius (mm) 180 Angle (mrad) <0.5 Axis (mm) except steerers 0.2 Current levels 5 Quads Integral field homogeneity + 5*10-5 Absolute integral field accuracy + 1*10-3 Multiplets Integral field homogeneity + 2*10-4 CERN GSI/CEA MM preparation meeting, 12.06.2015. 8

Magnetic measurements proposal of the FAIR magnets Rotating coil Reference radius 180 mm Maximum weight of the shaft 60 Kg Measurement integral length 3 m MRU inside the aperture 0.01 m 3m 220 mm diameter CERN GSI/CEA MM preparation meeting, 12.06.2015. 9

Multiplets Series test requirements Time costs days Installation SSW, check and positioning 1 Pre-cycling for 1 magnet 0.13 Worst case to be repeated 7 times (not for steerers): 2.73 days Measurement cycle 5 level (Gdl (x,y) and roll) 0.08 Fiducialize 0.06 Connection next magnet 0.12 Remove Wire, install shaft 1 Pre-cycling for 1 magnet 0.13 Positioning shaft 0.01 Worst case to be repeated 9 times (not for steerers): 3 days Measurement cycle 5 levels 0.08 Connection next magnet 0.12 Analysis 2 No margin or contingencies for other operations. Evaluate the hypothesis to go down to 3 current levels Total time 10 days CERN GSI/CEA MM preparation meeting, 12.06.2015. 10

Multiplets extended pre-series tests Full map with a short coil at 10 mm steps of: 1 long quad - 1 short quad - 1 sextupole - How many current levels? - Is it foreseen to shim to adjust the magnetic length or the homogeneity of the pre-series magnet ? - Integral field - integral transfer function - hysteresis and Homogeneity at 16 current levels - Cross-check measurements Cross-check of the field homogeneity with another system (a standard shaft at a smaller radius). - Cross-check measurements of the axis measurement performed with the SSW with another system (vibrating wire) - CERN GSI/CEA MM preparation meeting, 12.06.2015.

Multiplets extended pre-series tests Open questions: Will the local harmonics be used in particle tracking codes? - How is defined the polarity of the magnet w.r.t. the cryostat? (on the benches is possible to install the multiplet with different orientation) - If the magnets have different optical function in the machine are we measuring in the same configuration or in the final powering mode of the machine? - Should we measure the longitudinal magnetic centre? - CERN GSI/CEA MM preparation meeting, 12.06.2015.

Multiplets Rotating coil Open questions: Tangential or radial coil - Calibration / pcb coils - Measurements radius - Coil length - CERN GSI/CEA MM preparation meeting, 12.06.2015.

Multiplets Rotating coil Tangential N turns = 64 Surface absolute coil = 3.64 m2 L = 3 m Width = 38 mm (for the main quad) Output ~5 V @ 1Hz for the absolute at Inom Coil sensitivity up to 15th order reduced by a third for a measurement radius of 175 mm the coil sensitivity is close to zero around the 50th harmonic Still possible to extrapolate the harmonics to R=180 mm CERN GSI/CEA MM preparation meeting, 12.06.2015. 14

Multiplets Rotating coil Radial coil N = 128 Surface absolute coil = 3.84 m2 L = 3 m Width = 10 mm (for the main quad) Output ~5 V @ 1Hz for the absolute at Inom Coil sensitivity up to 15th order reduced by a third for a measurement radius of 175 mm Still possible to extrapolate the harmonics to R=180 mm CERN GSI/CEA MM preparation meeting, 12.06.2015. 15

Multiplets Rotating coil Radial coil (PCB) N = 60 (10 Turns * 6 Layers) Surface absolute coil = 1.26 m2 L = 2* 1.5 m Width = 7 mm (for the main quad) Output ~1.5 V @ 1Hz for the absolute at Inom measurement radius of 170 mm PRO CONS No need for surface calibration Very good compensation (~ 5000) weight Cost assembly Mechanical stability CERN GSI/CEA MM preparation meeting, 12.06.2015. 16

Multiplets Shaft length The one segment shaft with a fix rallonge can be used for all the multiplets (included the not standard) and to scan the longitudinal multipoles. - 3 m coils difficult winding and almost impossible to calibrate - 2 segments of ~ 1.5 m (standard winding or PCB) Reduce coil length Increase measurement time PCB boards no need of relative calibration (long quads measured with more than 1 measurements) Reduce the measurement radius to allow in situ calibration of absolute coil radius Only radial scheme and reduce measurement radius to 170 mm Increase system complexity Reduce requirements on absolute accuracy (rely on design) CERN GSI/CEA MM preparation meeting, 12.06.2015. 17

Multiplets Rotating coil: conclusions Reduce the measurements radius to 170 mm does not affect largely the coil sensitivity up to the 15th order A PCB coils shaft need only absolute calibration that could be done in situ w.r.t. a stretched wire measurements. For the relative calibration is possible to rely on the accuracy of the PCB board. In any case we need some margin on the shaft radius if we would calibrate in situ the shaft. 5% reduction of the measurement radius still allows extrapolation with a not large impact on the accuracy CERN GSI/CEA MM preparation meeting, 12.06.2015. 18