Understanding Green Chemistry Principles and Efficiency in Chemical Processes

Green chemistry focuses on designing sustainable chemical products and processes to minimize hazardous substances. It advocates for waste prevention, efficient reactions, and use of raw materials. Chemical engineers play a key role in optimizing percentage yield and atom economy for efficient production. Learn about calculating percentage yield, atom economy, and the significance of efficiency in the chemical industry.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

What is green chemistry? The sustainable design of chemical products and chemical processes. It minimises the use and generation of chemical substances that are hazardous to human health or the environment.

Green chemistry principles Better to prevent waste than to treat it or clean it up. Chemical processes should aim to incorporate all reactants in the final product. Chemical processes should aim to use and generate substances with minimal toxicity to human health and the environment.

Percentage Yield and Atom Economy Learn how the efficiency of a chemical reaction can be measured in terms of percentage yield and atom economy

Making only as much as we need PERCENTAGE YIELD and ATOM ECONOMY

Most of the substances we use every day are made from RAW MATERIALS, often through complex chemical reactions. Reactants (raw materials) Chemical reactions Products

Pottington Braunton The chemical industry is a multi billion pound international industry producing millions of products vital to our civilisation and well being. Chemical Engineers play a crucial role and are much in demand there are many opportunities and high levels of pay! Chemical Engineers are much concerned with: % YIELD and ATOM ECONOMY..

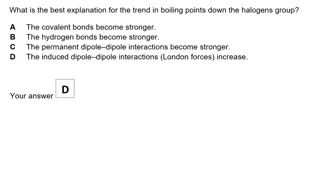

Percentage Yield In industry manufacturers will want to know how efficient their process is. This can be done by using the following equation: Percentage Yield = Actual Yield x 100 Theoretical Yield Theoretical Yield: Mass of product expected from a chemical reaction Mass of product actually obtained from carrying out the reaction Actual Yield:

% YIELD is the amount of product you actually make as a % of the amount you should theoretically make PRODUCT REACTANTS % YIELD ABOUT 75% + ACTUALLY make this much SHOULD make this much

Ex 1:Using the following equation calculate the percentage yield of propanol when 25kg of propene reacts with excess water producing 31kg of propanol. ActualYield: mass of product given in equation obtained from mole ratio calculation Theoretical Yield: C3H6 + H2O C3H7OH Hydration reaction

Step1: Theoretical yield calculation C3H6 1 mole 42g 1g C3H7OH 1 mole 60g 60g 42g Change g into kg 25kg 25kg x = 35.71kg 60kg 42kg Theoretical yield

Step2: percentage yield calculation Percentage Yield = Actual Yield x 100 Theoretical Yield = 31kg x 100% 35.71kg = 86.81%

PERCENTAGE YIELD 1 LIMESTONE (calcium carbonate) is used to make QUICKLIME (calcium oxide) for cement making RAM Ca 40 O 16 C 12 CaCO3 CaO + CO2 RFM: 100 56 44 So, THEORETICALLY, 100 tonnes of limestone should produce 56 tonnes of quicklime. Why? next slide BUT the ACTUAL YIELD is only 48 tonnes So..the PERCENTAGE YIELD is only 48 x 100 = 87.5% 56

PERCENTAGE YIELD 2 Very few chemical reactions have a yield of 100% because: The raw materials (eg limestone) may not be pure Some of the products may be left behind in the apparatus The reaction may not completely finish Some reactants may give some unexpected products Some reactions involve an equilibrium Careful planning and design of the equipment and reaction conditions can help keep % yield high

Atom economy In an ideal reaction, all reactant atoms end up as the product molecule. No waste is produced! Inefficient, wasteful reactions have low atom economy. Efficient processes have high atom economy and are important for sustainable development. They conserve natural resources and create less waste.

Atom economy Mass of desired product(s) % atom economy = x 100 Total mass of reactants is a measure of the proportion of reactant in the final useful product. a reaction may have a high percentage yield but a low percentage atom economy, or vice versa.

High atom economy All reactant atoms included in the desired product.

Low atom economy Some reactant atoms not included in the desired product.

Atom Economy Compare these two industrial reactions 2Mg + O2 2MgO What do you notice about each one? raw materials, useful products, waste products USEFUL PRODUCT (antacids, fire resistant coatings, electrical insulators) CaCO3 CaO + CO2 USEFUL PRODUCT (cement, glass, agriculture etc)

ATOM ECONOMY is the mass of the product you want as a % of the mass of all the products you make REACTANTS PRODUCTS + Stuff you also get but don t want Stuff you want ATOM ECONOMY about 50%

CALCULATING ATOM ECONOMY Often, chemical reactions produce unwanted products along with the product you want. ATOM ECONOMY is the mass of product you want as a % of the mass of all the reactants Waste product Useful product CaCO3 CaO + CO2 RFM: 100 56 44 ATOM ECONOMY mass useful product mass of all reactants = X 100% Atom Economy = 56 / (56 + 44) X 100 = 56 %

ATOM ECONOMY is the mass of product you want as a % of the mass of all the reactants 2Mg + O2 2MgO GFM: 48 32 80 Atom Economy = 80 / 80 x 100% = 100 % Fe2O3 + 3CO 2Fe + 3CO2 160 84 112 132 Atom Economy = 112 / 244 x 100% = 45.9 %

Find the atom economy for these 2 methods of extracting copper: 1. Heat copper oxide with carbon 2. Heat copper sulphide with oxygen RAM Cu 64, O 16, C 12, S 32 2CuO + C 2Cu + CO2 2(80) 12 128 CuS + O2 Cu + SO2 96 32 64 44 64 Mass of all reactants 160 + 12 = 172 128 172X 100 = 74.4 % Mass of copper = 128 Mass of copper = 64 Mass of all reactants = 96 + 32 = 128 64 128X 100 = 50 % ATOM ECONOMY ATOM ECONOMY = =

Real example: Paracetamol The non-prescription analgesic market (paracetamol, aspirin, ibuprofen) is worth about 21 billion annually. Maximising % yield and atom economy in the reactions shown is vital to save money and conserve energy and resources

SUMMARY % YIELD is the amount of product you actually make as a % of the amount you should theoretically make ATOM ECONOMY is the mass of the product you want as a % of the mass of all the products you make Stuff you also get but don t want % YIELD ABOUT 75% ATOM ECONOM Y about 50% Stuff you want ACTUALLY make this much SHOULD make this much High atom economy: All reactant atoms included in the desired product. Low atom economy: Some reactant atoms not included in the desired product.

CHEMICAL ENGINEERS must plan to maximise: ATOM ECONOMY by PERCENTAGE YIELD by Using the most EFFICIENT REACTION CONDITIONS & APPARATUS to Choosing the most EFFICIENT REACTION to make the product to Reduce energy use, costs and conserve raw materials Reduce waste and pollution

Ex1: What is the percentage atom economy for the following reaction for making hydrogen by reacting coal with steam? C(s) + 2H2O(g) CO2(g) 12 g 2(2 + 16) g [12 + (2 16)] g 2(2 1) g + 2H2(g) 12 g 36 g 44 g 4 g Total mass of reactants Mass of desired product = 12 + 36 = 48 g = 4 g

% atom economy = mass of desired product 100 total mass of reactants = 4 100 48 = 8.3% This reaction route has a very low atom economy and is an inefficient method of producing hydrogen.

Ex2:Calculate the percentage atom economy for the reaction below. CH3 H3 C CH3 acid H3 C C CH CH2 C C H3 C CH3 CH3 C6H12 C6H12 Total mass of reactants Mass of desired product = [(6 12) + (12 1)] = [(6 12) + (12 1)] = 84 g = 84 g

% atom economy = mass of desired product 100 total mass of reactants = 84 100 84 = 100% This reaction route has a very high atom economy as all reactant atoms are incorporated into the desired product.

Ex3: Hydrazine (N2H4) is used for rocket fuel. Calculate the atom economy for hydrazine production. 2NH3 NH3 2 mol 34 g + NaOCl + H2O NaCl + N2H4 N2H4 1 mol 32 g NaOCl 1 mol 74.5 g NaCl 1 mol 58 g H2O 1 mol 18 g Total mass of reactants Mass of desired product = 34 + 74.5 = 108.5 g = 32 g

% atom economy = mass of desired product 100 total mass of reactants = 32 100 108.5 = 30% This reaction route has an atom economy of 30%. The remaining 70% is waste product (NaCl and H2O).

Catalysts Have a crucial role in improving atom economy. Allow the development of new reactions requiring fewer starting materials and producing fewer waste products. Can be recovered and re-used. Allow reactions to run at lower temperatures, cutting energy requirements.

Methanol Methanol is a potential fuel of the future It can be made from methane Methane can be made by anaerobic fermentation of waste organic material Laptop with methanol fuel cell green technology

Methanol It is added to other fuels, it is the fuel for drag car racing and it is being widely used in fuel cells to power.

Carbon neutral? If methane is combusted in a limited supply of oxygen, carbon monoxide forms CH4 + O2 CO + 2H2 Synthesis gas The products are then passed over a catalyst at 50- 100 atmospheres and 250oC CO + 2H2 CH3 OH

Carbon neutral? CO + 2H2 CH3 OH 28 4 32 Atom economy = mass of desired products x 100 Total mass of reactants = 32 16 + 16 x 100 = 100%

Carbon neutral? All the carbon in the methane is converted into carbon in the methanol it is said to be carbon neutral The carbon dioxide released when methanol burns contains the same amount of carbon that was reclaimed from the CO The amount of carbon dioxide released when the methanol burns is the same as the amount the methane would have released if it was burned completely. No additional carbon dioxide results from the process. The Methane comes from the anaerobic fermentation of waste organic materials.

Green Chemistry Look at the 12 principles of Green Chemistry How many of them apply to this process? The catalysts are zinc oxide, aluminium oxide or copper.

Preparation of zinc sulphate Zinc sulphate is used as a paste, mixed with zinc oxide to treat acne. Aim to produce zinc sulphate and calculate the % yield

Preparation of zinc sulphate It is an astringent it closes the pores of the skin to keep out bacteria This product contains peroxide, zinc sulphate, tea tree oil and sage

Preparation of zinc sulphate It can also be used to prevent sunburn!

What to do Add a weighing boat to the balance and zero it Add between 2.2 2.5 g zinc oxide Record the accurate mass Measure out 25cm3 1.0 moll-1 H2SO4 Heat the acid to about 50oC Add the zinc oxide, stirring constantly

What to do next Cool the reaction mixture Weigh an evaporating dish and record the mass accurately Weigh a filter paper, fold the filter paper, place in a funnel and filter the zinc sulphate solution into the dish Heat to nearly dry, then leave to fully evaporate and cool. Reweigh the dish and product

Calculation % Yield Write the balanced equation Which reactant is in excess and which one limits the amount of product formed? How much product is expected (using the limiting reactant in the calculation) Calculate the yield = actual mass x 100 expected mass

Preparation of sodium citrate % yield Sodium citrate is a food additive (E331) e.g. in pepsi

What to do Weigh a beaker accurately Add approx 2g citric acid to the beaker and reweigh Add 25cm3 1.0 moll-1 NaOH and stir until all the crystals have dissolved Evaporate the beaker almost to dryness then leave to dry completely Reweigh the beaker

For the calculation 3 mol NaOH reacts with 1 mol citric acid Na + 3H2O + 3NaOH Na Na

The calculation 1. 3NaOH + C6H8O6 C6H5O7Na3 + 3H2O 2. Work out the theoretical yield. 3. Use the actual yield from your results and the theoretical yield to calculate the percentage yield.