John Deere Super Caddy 2 Operator’s Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

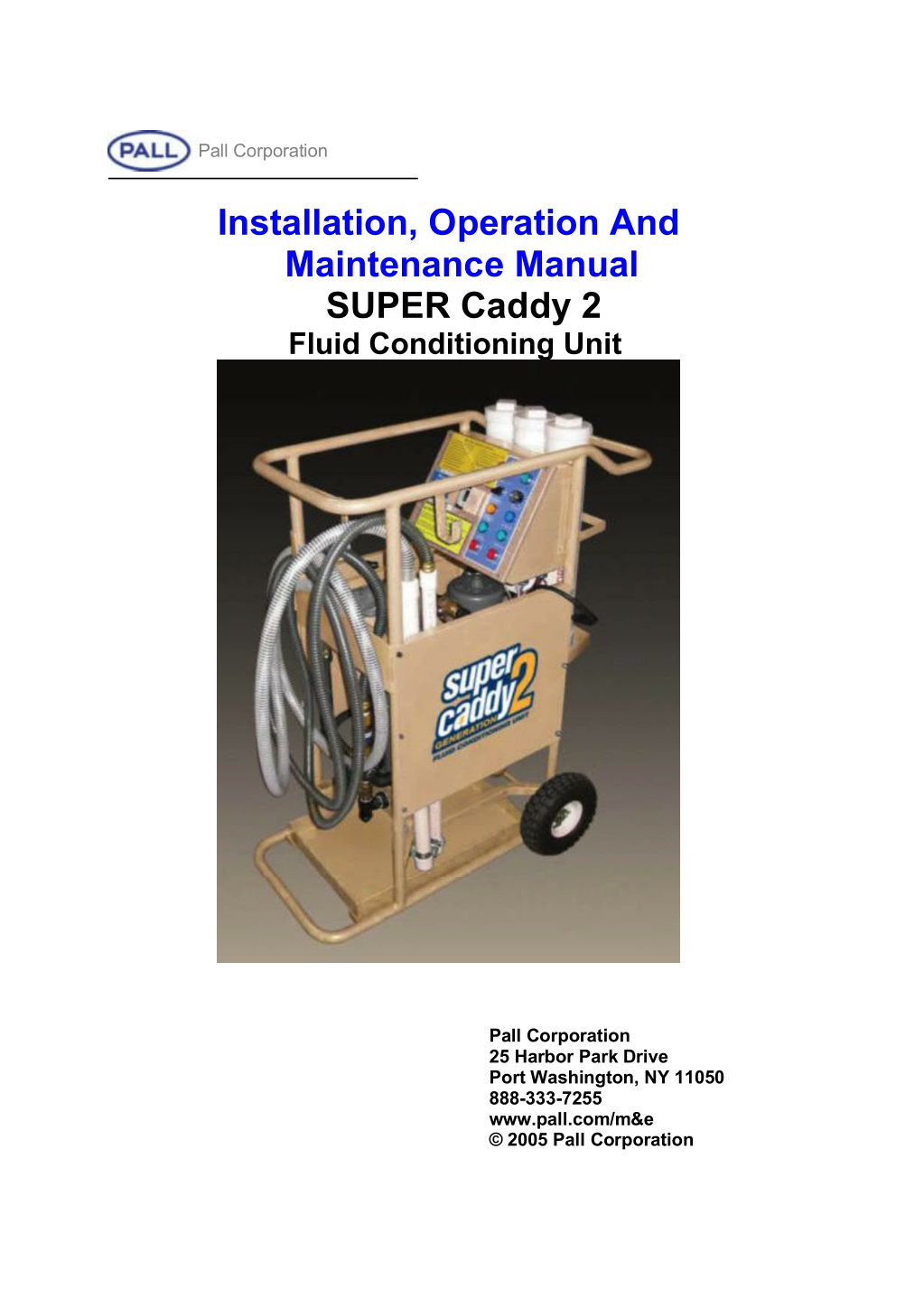

Pall Corporation Installation, Operation And Maintenance Manual SUPER Caddy 2 Fluid Conditioning Unit Pall Corporation 25 Harbor Park Drive Port Washington, NY 11050 888-333-7255 www.pall.com/m&e 2005 Pall Corporation

Pall Corporation CONTENTS Foreword ........................................................................................................3 Warnings, Cautions, and Notes....................................................................4 Specifications.................................................................................................6 Controls and Indicators.................................................................................7 Operation......................................................................................................10 Maintenance.................................................................................................12 Recommended Spares......................................................................12 Servicing Filter elements..................................................................12 Particulate Filter...................................................................12 Water Filter...........................................................................14 Strainers...............................................................................15 Variable Speed Drive and Motor......................................................15 Particle Counter ...............................................................................17 Trouble Shooting................................................................21 Clearing Blockage in Particle Counter.............................22 Troubleshooting Guide ...............................................................................23 Warranty.......................................................................................................24 Should a condition occur that requires assistance beyond that covered in this manual, please contact Pall Corporation s Technical support group at 1-888-333-7255. 2

Pall Corporation FOREWORD This manual is provided to serve as the installation, operation and maintenance guide for the equipment supplied. The contents should be read before attempting any phase of installation, operation and maintenance. The equipment and any optional items are packed individually for assembly by the customer. Unpack carefully and check all items received against the invoice. This equipment has been tested and quality controlled in accordance with Pall standard procedures. However, the equipment as shipped may have been opened or disassembled for draining, cleaning, etc., after testing. The customer should satisfy himself that no nuts, bolts, hoses or any other component has worked loose during shipment; these should be tightened wherever necessary. It is the user's responsibility to check actual operating conditions to ensure that the filter elements, cartridges, vessel and sealing materials are compatible with the application and are within local safety codes. TRADEMARKS & INTELLECTUAL PROPERTY Pall and The design of this equipment and all associated documentation is copyright of Pall Corporation 2005. are trademarks of the Pall Corporation. 3

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

Pall Corporation WARNINGS, CAUTIONS AND NOTES Recognize Safety Information This is the safety alert symbol. When you see this symbol on your machine or in this manual, be alert for the potential of personal injury. Follow the precautions and safe operating practices highlighted by this symbol. DANGER DANGER DANGER A signal word DANGER, WARNING, or CAUTION used with the safety alert symbol. DANGER identifies the most serious hazards. General precautions are on CAUTION labels. CAUTION CAUTION CAUTION WARNING WARNING WARNING Follow Safety Instructions Read the safety messages in this manual and on the machine. Follow these warnings and instructions carefully. Review them frequently. Be sure all operators of this machine understand every safety message. Replace safety labels immediately if missing or damaged. Operate Only If Qualified Do not operate this machine unless you have read the operator s manual carefully and you have been qualified by supervised training and instruction. Familiarize yourself with the job site and your surroundings before operating. Inspect Machine Inspect the equipment carefully before each use. Keep all parts in good condition and properly installed. Fix damage and replace worn or broken parts immediately. Pay special attention to hydraulic hoses and electrical power cord. Handle Fluids Safely Avoid Fires Filtering of fuel or other flammable liquids is not recommended. Store flammable fluids away from fire hazards. Do not incinerate or puncture pressurized containers. Make sure machine is clean of trash, grease, and debris. Do not store oily rags; they can ignite and burn spontaneously. Prepare for Emergencies Be prepared if a fire starts. Keep a first aid kit and fire extinguisher handy. Keep emergency numbers for doctors, ambulance service, hospital, and fire department near your telephone. Practice Safe Maintenance Understand service procedure before doing work. Work area should level, clean, and dry. Before servicing machine: - Position machine on a level surface - Allow to cool if hot Keep all parts in good condition and properly installed. Fix damage immediately. Replace worn or broken parts. Remove any buildup of grease, oil, or debris. 4

Pall Corporation Handle Chemical Products Safely Direct exposure to hazardous chemicals can cause serious injury. Potentially hazardous chemicals used with John Deere equipment include such items as lubricants, coolants, paints, and adhesives. A Material Safety Data Sheet (MSDS) provides specific details on chemical products: physical and health hazards, safety procedures, and emergency response techniques. Check the MSDS before you start any job using a hazardous chemical. That way you will know exactly what the risks are and how to do the job safely. Then follow procedures and recommended equipment. (See your John Deere dealer for MSDS documents on chemical products used with John Deere equipment). Wear Protective Clothing Wear close fitting clothing and safety equipment appropriate to the job. Operating equipment safely requires the full attention of the operator. Do not wear radio or music headphones while operating the machine. Service Machines Safely Tie long hair behind your head. Do not wear a necktie, scarf, loose clothing, or necklace when you work near machine tools or moving parts. If these items were to get caught, severe injury could result. Remove rings and other jewelry to prevent electrical shorts and entanglement in moving parts. Work In Ventilated Area Engine exhaust fumes can cause sickness or death. If it necessary to run an engine in an enclosed area, remove the exhaust fumes from the area with an exhaust pipe extension. If you do not have an exhaust pipe extension, open the doors and get outside air into the area. Illuminate Work Area Safely Illuminate your work area adequately but safely. Use a portable safety light for working inside or under the machine. Make sure the bulb is enclosed by a wire cage. The hot filament of an accidentally broken bulb can ignite spilled fuel or oil. 5 Work In Clean Area Before starting a job: - Clean work area and machine - Make sure you have all necessary tools to do your job. - Have the right parts on hand. - Read all instructions thoroughly; do not attempt shortcuts. Use Proper Tools Use tools appropriate to the work. Makeshift tools and procedures can create safety hazards. For loosening and tightening hardware, use the correct size tools. DO NOT use U.S. measurement tools on metric fasteners. Avoid bodily injury caused by slipping wrenches. Use only service parts meeting John Deere specifications. Dispose of Waste Properly Improperly disposing of waste can threaten the environment and ecology. Potentially harmful waste used with John Deere equipment include such items as oil, fuel, coolant, brake fluid, filters, and batteries. Use leak-proof containers when draining fluids. Do not use food or beverage containers that may mislead someone into drinking from them. Do not pour waste onto the ground, down a drain, or into any water source. 5

Pall Corporation SUPER CADDY SPECIFICATIONS Process Fluid Type: Hydraulic and lubricating oils having a minimum flash point of 200 F (93 C) per ASTM D92 or 180 F (82 C) per ASTM D93. Seal Compatibility: Nitrile seals: compatible with most mineral based oils. Inlet Fluid Temperature: +160 F (66 C) MAX Inlet Pressure: 14 HG to 15 PSIG (a positive inlet pressure may damage pump shaft seals and cause fluid loss) Fluid Circulation Rate: 0-13 GPM (0-49 LPM) Operating Viscosity: 1300 SUS (260 cSt) MAX Electrical Power Requirements: 120 VAC, 1 Phase, 60 Hz, 19.5 Amp Hose Connections: Inlet: 1 NPT, Hose 15 with 3 x 1 304 SS wand Outlet: NPT, Hose 15 with 3 x 304 SS wand Electrical Control Box: NEMA 12 consolette containing PLC, variable speed drive, operation controls, indicator lights, particle counter display, water sensor display, USB connection Motor: 1 HP, 90 VDC Variable Speed Pump: Marzocchi external gear pump, 1.713 cubic inch displacement; flow rate to 13 gpm at 1750 rpm; 125 psi internal relief valve Wheels: 10-inch pneumatic wheels Particle Filter: Pall Ultipleat SRT filter particle removal filter assembly. Particle filter removal rating: x(c)=1000 Pall PallSorbTM water removal filter assembly. Filter element removes free water. Water Removal Filter: Particle Counter: Laser particle transducer and display for measuring particle contamination; reports data (at 5 minute intervals) as ISO 4406 cleanliness code. Download results to a PC via USB connection. Water Sensor: Monitors dissolved water content in system fluid and displays measurement as percent of fluid saturation. 6

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

Pall Corporation CONTROLS AND INDICATORS Stop Button Start Button Speed Control Dial Manual/Auto Mode Selector Switch Cold Start Indicator Water Sensor Water Filter OK Indicator Plugged Water Filter Indicator Particle Counter Shut Down (Clean Fluid) Indicator Particle Filter OK Indicator Plugged Particle Filter Indicator Control/Indicator Stop Push Button Description A detented red mushroom head push button. When depressed push button will remain in the depressed condition until operator pulls to reset. Unit will not operate when button is depressed. Stops unit operation of motor. A green illuminated push button. Button will flash when caddy is in the ready condition. Depress to start unit. Button will remain steady green while unit is running. Start push button will not be illuminated when stop push button is in the depressed position. A 5K potentiometer that controls motor speed. Speed is variable between 0- 1750 RPM. Scale is graduated in percentage of full speed. Start Push Button Speed Control Dial 7

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com