Understanding Material and Energy Balances in Environmental Systems

Tools and concepts for quantitative analysis in environmental systems include material and energy balances. Conservation laws dictate that matter and energy cannot be created or destroyed, only transformed. This analysis helps in accounting for the flow of energy and materials in and out of environmental systems, vital for sustainable management.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Tools for quantitative understanding of the behavior of environmental systems. For accounting of the flow of energy and materials into and out of the environmental systems.

Material Balance Energy Balance Pollutant Energy modeling production, transport, and fate

Conservation of Matter The law of conservation of matter states that (without nuclear reaction) matter can neither be created nor destroyed. We ought to be able to account for the matter at any point in time. The mathematical representation of this accounting system is called a materials balance or mass balance.

Conservation of Energy The law of conservation of energy states that energy cannot be created or destroyed. Meaning that we should be able to account for the energy at any point in time. The mathematical representation of this accounting system we use to trace energy is called an energy balance.

The simplest form of a materials balance or mass balance Accumulation = input output input Accumulation output Environmental System (Natural or Device)

Control Volume Food to people Consumer goods Accumulation Solid Waster

Mass rate of accumulation = Mass rate of input Mass rate of output

Selam is filling her bathtub but she forgot to put the plug in. if the volume of water for a bath is 0.350 m3 and the tap is flowing at 1.32 L/min and the drain is running at 0.32 L/min, how long will it take to fill the tub to bath level? Assuming Selam shuts off the water when the tub is full and does not flood the house, how much water will be wasted? Assume the density of water is 1,000 kg/m3

Vaccumulation Qout = 0.32 L/min Qin = 1.32 L/min We must convert volumes to masses. Mass = (volume)(density) Volume = (flow rate)(time) = (Q)(t)

From mass balance we have Accumulation = mass in mass out (Vacc)( ) = (Qin)( )(t) - (Qin)( )(t) Vacc = (Qin)(t) (Qin)(t) Vacc = 1.32t 0.32t 350L = (1.00 L/min)(t) t= 350 min or 5.833 hr The amount of wasted water is Waste water = (0.32)(350) = 112 L

Mass= (concentra tion)(flow rate) Mass flow rate = time dM = c Q c Q Mass balance in in out out dt C Q C Q dM dt = in in C out out Efficiency of a system C Q Q in in in in mass in mass out = OR mass in

The air pollution control equipment on a municipal waste incinerator includes a fabric filter particle collector (known as a baghouse). The baghouse contains 424 cloth bags arranged in parallel, that is 1/424 of the flow goes through each bag. The gas flow rate into and out of the baghouse is 47 m3/s, and the concentration of particles entering the baghouse is 15 g/m3. In normal operation the baghouse particulate discharge meets the regulatory limit of 24 mg/m3. Calculate the fraction of particulate matter removed and the efficiency of particulate removal when all 424 bags are in place and the emissions comply with the regulatory requirements. Estimate the mass emission rate when one of the bags is missing and recalculate the efficiency of the baghouse. Assume the efficiency for each individual bag is the same as the overall efficiency for the baghouse.

Cout = 24 mg/m3 Qout = 47 m3/s Baghouse Cin = 15 g/m3 Qin = 47 m3/s Accumulation = particle removal Hopper

dM = c Q c Q in in out out dt ?? ??= (15,000mg/m3)(47m3/s)-(24mg/m3)(47m3/s)=703,872 mg/s The fraction of particulates removed is 703,872??/? (15,000??/?3)(47??/?)=703,872??/? 705,000??/?= 0.9984 The efficiency of the baghouse is =15,000 ??/?3 24 ??/?3 15,000 ??/?3 =99.84% (100%)

Cemission= ? Qemission= 47 m3/s Cin = 15 g/m3 QBypass =(1/424)( 47 m3/s) Bypass Cout= ? Qout= (423/424)47 m3/s Baghouse Cin = 15 g/m3 Qin =(423 424 )( 47 m3/s) ?? ??= ? Control Volume

A control volume around the baghouse alone reduces the number of unknowns to two: Because we know the efficiency and the influent mass flow rate, we can solve the mass balance equation for the mass flow rate out of the filter. Q C = C Q in in C out out Q in in Solving for CoutQout CoutQout =(1- )CinQin= (1-0.9984)(15,000mg/m3)(47m3/s)(423 =1,125mg/s 424)

Effluent ?? ??=CinQin from bypass +CinQin from baghouse-CemissionQemission Because there is no accumulation in the junction ?? ??=0 and the mass balance equation CoutQout=CinQin from bypass +CinQin from baghouse = (15,000mg/m3)(47m3/s)(1/424)+1,125=2788 mg/s The concentration in the effluent is ???????? ???? Bypass From baghouse = 2,788 mg/s 47?3/? = 59 mg/m3 The overall efficiency of the baghouse with missing bag is =15,000 ??/?3 59 ??/?3 15,000 ??/?3 (100%)= 99.61%

A storm sewer is carrying snow melt containing 1.200 g/L of sodium chloride into a small stream. The stream has a naturally occurring sodium chloride concentration of 20 mg/L. If the storm sewer flow rate is 2.00 L/min and the stream flow rate is 2.0 m3/s, what is the concentration of salt in the stream after the discharge point? Assume that the sewer flow and the storm flow are completely mixed, that the salt is a conservative substance (it does not react) and that the system is at steady state.

kinetic reactions : reactions that are time dependent. Reaction kinetics: the study of the effects of temperature, pressure, and concentration on the rate of a chemical reaction.

The rate of reaction, ri, the rate of formation or disappearance of a substance. ?? ??=?(??) ?? ?? +r, r=-KCn Homogenous reactions. single phase reactions Heterogeneous reactions : multiphase reactions (between phases surface) ?(???)

ri = kf1(T,P);f2([A],[B], ) Rate constant Concentration of reactant Assuming that the pressure and temperature are constant aA + bB cC Rate of reaction rA = - k[A] [b] = k[C]

Rate of reaction rA = - k[A][b] = k[C] order of reaction = + , the order with respect to reactant A is , to B is , and to product C is . rA = -k zero-order reaction rA = -k[A] first-order reaction rA = -k[A2] second-order reaction rA = -k[A][B] second-order reaction

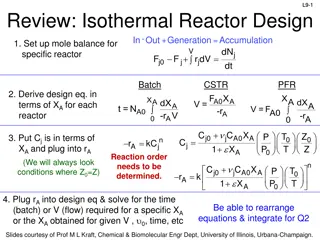

batch reactors and flow reactors. fill-and-draw material flows into, through, and out of the reactor Unsteady state

IDEAL REACTORS REAL REACTOR

Conserved system: where no chemical or biological reaction takes place and no radioactive decay occurs for the substance in the mass balance. Steady-state: Input rate = Output rate Accumulation =0

Decay rate = 0 Accumulation rate = 0 Qs Stream Qm Cs Mixture Cm Qw Q = flow rate C = concentration Wastes Cw CsQs + QwCw = QmCm

For non-conservative substances Accumulation rate = input rate output rare transformation rate

With first-order reactions Total mass of substance = concentration x volume when V is a constant, the mass rate of decay of the substance is first-order reactions can be described by r = -kC=dC/dt,

A well-mixed sewage lagoon is receiving 430 m3/d of sewage out of a sewer pipe. The lagoon has a surface area of 10 ha and a depth of 1.0m. The pollutant concentration in the raw sewage discharging into the lagoon is 180 mg/L. The organic matter in the sewage degrades biologically in the lagoon according to first-order kinetics. The reaction rate constant is 0.70 d-1. Assuming no other water losses or gains and that the lagoon is completely mixed, find the steady-state concentration of the pollutant in the lagoon effluent.

Decay Cin = 180 mg/L Qin = 430 m3/d Ceff = ? Qeff = 430 m3/d Sewage Lagoon Control volume Accumulation=input rate output rate decay rate Assuming steady-state condition, accumulation = 0 input rate = output rate + decay rate CinQin = CeffQeff + (K)(Clagoon)(V) Ceff=1.10mg/ L

( dt ) ( ) d in d out = = 0 dM/dt = ? dt dM = kCV dt dM= dC dC = V = kt kC C C oe dt dt dt

Mass balance for each plug element in ( ) ( ) C ( ) dM d d out d = + V dt dt dt dt No mass exchange occurs across the plug boundaries, d(in) and d(out) = 0 dC dM= dC = kt C C e = kC V out in dt dt dt

k = C C e in out Residence time L=length The residence time for each plug: ( ( ) ) L A V = = ( ( ) ) u A Q ( ) C L V = = = ln out k k k ( ) C u Q in

A wastewater treatment plant must disinfect its effluent before discharging the wastewater to a near-by stream. The wastewater contains 4.5 x 105 fecal coliform colony-forming units (CFU) per liter. The maximum permissible fecal coliform concentration that may be discharged is 2,000 fecal coliform CFU/L. It is proposed that a pipe carrying the wastewater be used for disinfection process. Determine the length of the pipe required if the linear velocity of the wastewater in the pipe is 0.75 m/s. Assume that the pipe behaves as a steady-state plug-flow system and that the reaction rate constant for destruction of the fecal coliforms is 0.23 min-1.

Cin=4.5x105 CFU/L U=0.75 m/s Cout=2,000 CFU/L U=0.75 m/s Using the steady-state solution on the mass-balanceequation, we obtain L K C in C = ln out u 2000 / CFU L L = = 1 ln 23 min 5 5 . 4 10 x / . 0 ( 75 / )( 60 / min) CFU L m s s Solving for the length of pipe, we have ln(4.44x10-3)=-0.23min-1 L=1,060m ? 45?/???

A contaminated soil is to be excavated and treated in a completely mixed aerated lagoon. To determine the time it will take to treat the contaminated soil, a laboratory completely mixed batch reactor is used to gather the following data. Assuming a first-order reaction, estimate the rate constant, k, and determine the time to achieve 99 % reduction in the original concentration. Time (d) 1 16 Waste Concentration (mg/L) 280 132

Using the 1st and 16th day, the time interval t= 16-1 = 15 d 132 / mg L C = 15 ( ) k d e = kt t e 280 / mg L C o Solving for k, we have k = 0.0501 d-1 To achieve 99 % reduction the concentration at Time t must be 1 0.99 of the original concentration C = = . 0 05 ( ) t . 0 01 t e t = 92 days C o

Concentration, Cin 0 0 0 Time Time Time Step increase Step decrease pulse/spike increase

Concentration, Cin 0 1/k Time Decay 1/k Time Time C Formation = kt t e C o

C1 C1 Concentration, Cin Concentration, Cin -0.37C0 + 0.63C1 C0 C0 0 t= 0 Time Time Effluent concentration Influent concentration Concentration, Cin Concentration, Cin C0 C0 0.37C0

For balanced flow (Qin = Qout) and no reaction, the mass balance becomes dM = c Q c Q in in out out dt Where M = CV. The solution is = C Ct exp 0 t t + 1 exp C 1 Where = V/Q

Flushing of nonreactive contaminant from a CMFR by a contaminant-free fluid Which means Cin = 0 and the mass balance becomes dM = outQ c out dt Where M = CV. The initial concentration is C0=M/V t = For time t 0 we obtain exp Ct C 0

Before entering an underground utility vault to do repairs, a work crew analyzed the gas in the vault and found that it contained 29mg/m3 of H2S. Because the allowable exposure level is 14 mg/m3 the work crew began ventilating the vault with a blower. If the volume of the vault is 160 m3 and the flow rate of contaminant-free air is 10 m3/min, how long will it take to lower the H2S level to that will allow the work crew to enter? Assume the manhole behaves as CMFR and that H2S is nonreactive in the time period considered.

For balanced flow (Qin = Qout) and first-order reaction the mass balance becomes dM = C Q C Q kC V in in out out out dt Where M = CV. By dividing with Q and V we have 1 dC ( ) = C C kC in out out dt

For stead-state conditions dC/dt=0 C C out + Decay C =1 o =1 o C OR k out k Formation Co Co Concentration, Cin Concentration, Ceff 0 0 Time Time

A step decrease in influent concentration (Cin=O) for non-steady-state conditions with first-order decay dM = 0 C Q kC V out out out dt Where M = CV. By dividing with Q and V we have 1 dC C = + k C = exp o C C t out dt out o + 1 k

Concentration, Cin Concentration, Cin C0 C0 0 0 Time Time Effluent concentration Influent concentration