Volvo L50D Wheel Loader Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

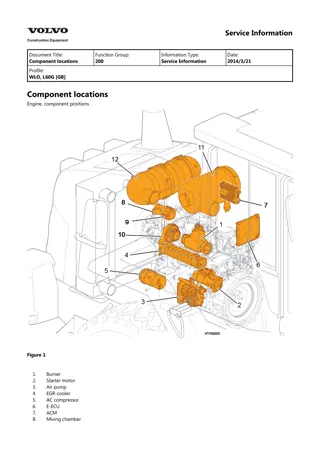

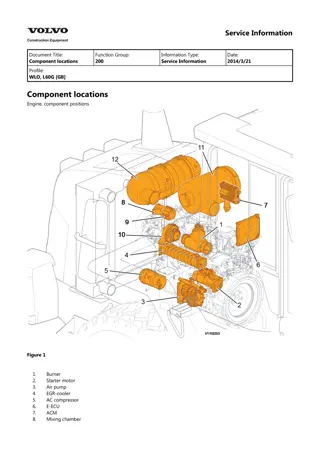

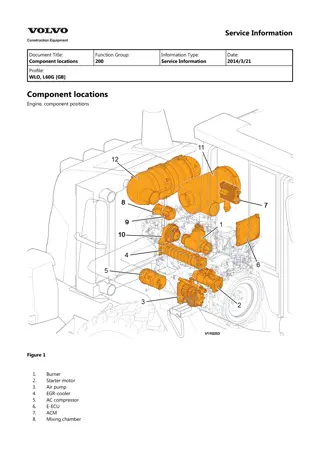

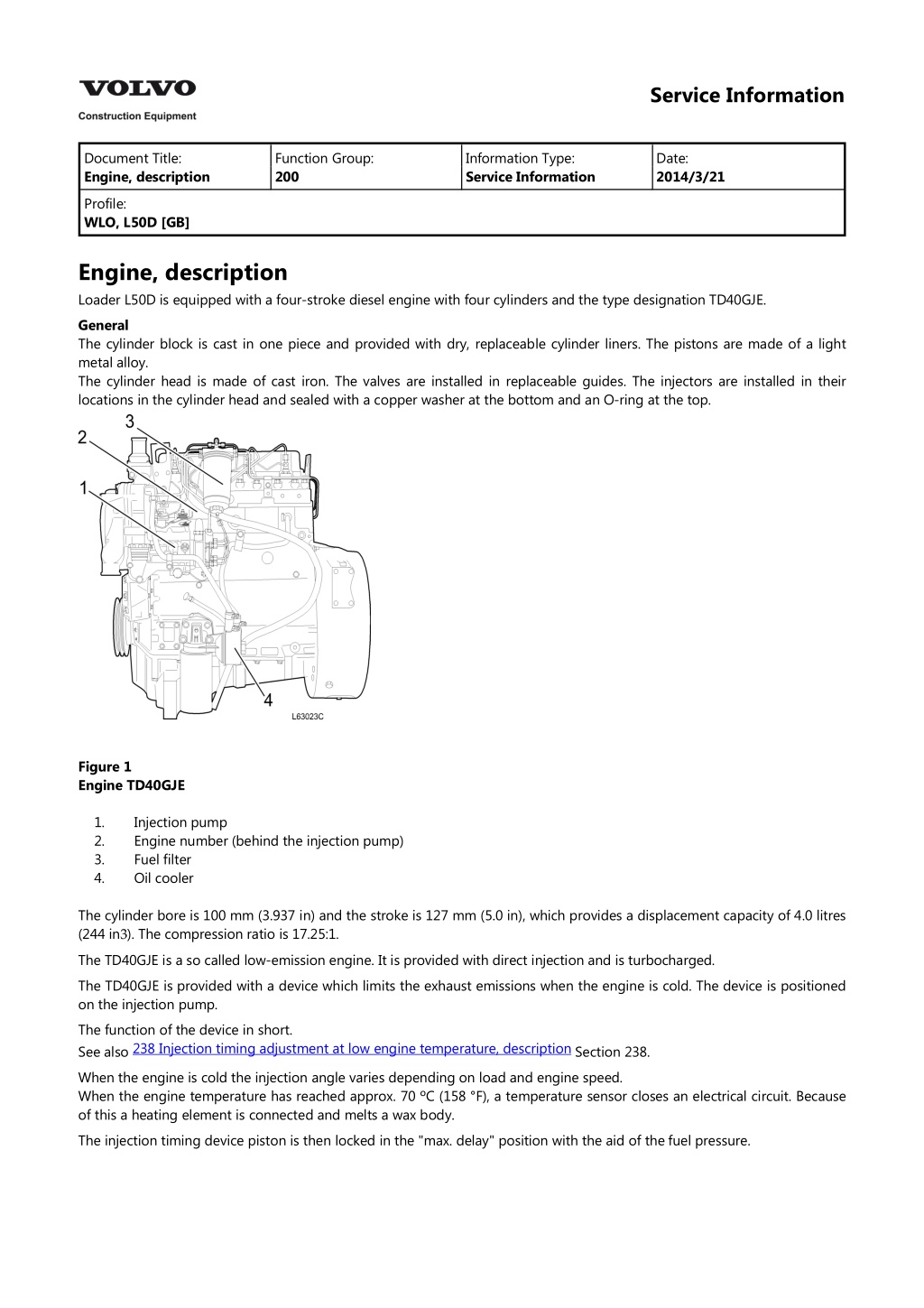

Service Information Document Title: Engine, description Function Group: 200 Information Type: Service Information Date: 2014/3/21 Profile: WLO, L50D [GB] Engine, description Loader L50D is equipped with a four-stroke diesel engine with four cylinders and the type designation TD40GJE. General The cylinder block is cast in one piece and provided with dry, replaceable cylinder liners. The pistons are made of a light metal alloy. The cylinder head is made of cast iron. The valves are installed in replaceable guides. The injectors are installed in their locations in the cylinder head and sealed with a copper washer at the bottom and an O-ring at the top. Figure 1 Engine TD40GJE 1. 2. 3. 4. Injection pump Engine number (behind the injection pump) Fuel filter Oil cooler The cylinder bore is 100 mm (3.937 in) and the stroke is 127 mm (5.0 in), which provides a displacement capacity of 4.0 litres (244 in3). The compression ratio is 17.25:1. The TD40GJE is a so called low-emission engine. It is provided with direct injection and is turbocharged. The TD40GJE is provided with a device which limits the exhaust emissions when the engine is cold. The device is positioned on the injection pump. The function of the device in short. See also When the engine is cold the injection angle varies depending on load and engine speed. When the engine temperature has reached approx. 70 C (158 F), a temperature sensor closes an electrical circuit. Because of this a heating element is connected and melts a wax body. The injection timing device piston is then locked in the "max. delay" position with the aid of the fuel pressure. 238 Injection timing adjustment at low engine temperature, description Section 238.

Figure 2 Engine TD40GJE 1. 2. 3. Feed pump Turbocharger Cold-starting device (Type Thermostart) The engine compartment is fully enclosed which lowers the sound level both outside the machine an inside the cab. The engine cooling system is based on a concept, which entails an integrated cooling of the engine, transmission and the hydraulics. The degree of cooling of these systems is dependent of the cooling fan speed. The engine cooling fan is driven by a vane motor positioned in front of the radiator. The fan drive is hydrostatic and powered by a variable axial piston pump. See also The serial number can be found on a plate, which is positioned behind the injection pump. Type designation and serial number are given on a plate by the oil dipstick on the right side of the machine. 263 Hydraulic cooling fan, description , Section 263.

Service Information Document Title: Engine, removing Function Group: 210 Information Type: Service Information Date: 2014/3/21 Profile: WLO, L50D [GB] Engine, removing Op nbr 21070 ratchet block shackle sling 1. Break the connection from the battery by turning off the battery disconnect switch. 263 Fan motor, removing 2. Remove the hydraulic motor for cooling fan. See . 3. Drain off the engine oil and the coolant from the engine. Disconnect the engine oil draining hose. 4. Remove the side covers. 5. Disconnect the flexible hose and the inlet hose from the turbocharger. Plug all exposed openings. 6. Disconnect the coolant hoses from the expansion tank. Detach the engine hood and lift it away together with the expansion tank, air cleaner and silencer. 7. Disconnect hoses, sensors, fuel and electrical leads from the engine. 8. Take apart connector BZ, positioned by the fuel filler pipe. 9. Remove the fan shroud from the radiator. 10. Disconnect all hoses, cables and other items from the engine. 11. Remove AC compressor and its bracket and other equipment. 12. Remove the operator seat. The weight of the seat is 45 kg (99 lb) 13. Fold back the floor mat and remove the rear cover plate from the cab floor. 14. With the aid of for example ratchet blocks and lifting slings, suspend the hydrostatic pump and the hydraulic pumps at the front and rear ends.

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

Figure 1 Suspension of hydrostatic and hydraulic pumps, front end. Figure 2 Suspension of hydrostatic and hydraulic pumps, rear end. 1. Ratchet block 15. Connect lifting slings to the engine. Use the attaching devices installed on the engine. The weight of the engine is approx. 450 kg (992 lb).

Figure 3 Lifting slings connected to engine 1. Rear engine mounting 16. Remove the front engine mountings. Figure 4 Removing front engine mountings 17. Remove the bolts retaining the rear engine mountings against the rubber elements. 18. Loosen the four attaching bolts for the radiator cowl and incline the cowl slightly rearward. Position a spacer sleeve on both sides and secure with bolts.

Figure 5 1. Spacer sleeve 19. Remove the bolts in the joint between the diesel engine and the hydrostatic pump. Figure 6 Bolted joint between diesel engine and hydrostatic pump. 1. 2. Bolt Hydrostatic pump 20. Pull the engine slightly outward and then lift it out of the machine. The weight of the engine is 450 kg (992 lb) 21. Move any optional equipment to the engine which is to be installed. 22. Check the connecting parts for wear, that is the hub and flexible disc, between the diesel engine and the hydrostatic motor. Change necessary parts. NOTE! In order not to considerably reduce the service life of both flexible disc and hub they must be re-installed in a particular way. See 440 Hydrostatic pump, installingdamping element and hub .

Figure 7 Connecting parts, hydrostatic unit side 1. Hub 23. Clean the engine compartment. Figure 8 Connecting parts, diesel engine side 1. Flexible disc

Service Information Document Title: Engine, installing Function Group: 210 Information Type: Service Information Date: 2014/3/21 Profile: WLO, L50D [GB] Engine, installing Op nbr 1. Align the flexible disc lugs and hub lugs, so that engine and pump can dock. 2. Lift the engine into position. When necessary adjust the engine inclination with the ratchet blocks. NOTE! Bear in mind that the engine lifting points are positioned diagonally. 3. Install and tighten down the bolts between the engine and the hydrostatic pump. 4. Install and torque-tighten the bolts for the engine mountings. Tightening torque: 78 Nm (58 lbf ft) 5. Remove all lifting devices, lifting slings, lifting hooks etc. Install the oil draining nipple. 6. Install the rear cover plate for the cab floor and lay down the floor matt. 7. Install the operator seat. The weight of the seat is 45 kg (99 kg). 8. Connect hoses, cables and other items to the engine. 9. Install the oil draining hose. 10. Assemble connector BZ . 11. Install the engine hood. 12. Install the fan. 13. Connect the hose to the turbocharger and the silencer. 14. Install the engine side covers. 15. Fill with coolant. 16. Fill with engine oil. 17. Bleed the fuel system. 18. Reconnect the positive cable to the battery. 19. Reconnect the battery current with the battery disconnect switch. 20. Start the engine and check its functions. 21. Recheck oil and coolant levels.

Service Information Document Title: Engine, installing Function Group: 210 Information Type: Service Information Date: 2014/3/21 Profile: WLO, L50D [GB] Engine, installing Op nbr 1. Align the flexible disc lugs and hub lugs, so that engine and pump can dock. 2. Lift the engine into position. When necessary adjust the engine inclination with the ratchet blocks. NOTE! Bear in mind that the engine lifting points are positioned diagonally. 3. Install and tighten down the bolts between the engine and the hydrostatic pump. 4. Install and torque-tighten the bolts for the engine mountings. Tightening torque: 78 Nm (58 lbf ft) 5. Remove all lifting devices, lifting slings, lifting hooks etc. Install the oil draining nipple. 6. Install the rear cover plate for the cab floor and lay down the floor matt. 7. Install the operator seat. The weight of the seat is 45 kg (99 kg). 8. Connect hoses, cables and other items to the engine. 9. Install the oil draining hose. 10. Assemble connector BZ . 11. Install the engine hood. 12. Install the fan. 13. Connect the hose to the turbocharger and the silencer. 14. Install the engine side covers. 15. Fill with coolant. 16. Fill with engine oil. 17. Bleed the fuel system. 18. Reconnect the positive cable to the battery. 19. Reconnect the battery current with the battery disconnect switch. 20. Start the engine and check its functions. 21. Recheck oil and coolant levels.

Service Information Document Title: Valves, adjusting Function Group: 214 Information Type: Service Information Date: 2014/3/21 checking and Profile: WLO, L50D [GB] Valves, checking and adjusting Op nbr 21412 Valve clearance cold or warm engine Inlet Exhaust 0.20 mm (0.008 in) 0.45 mm (0.018 in) 1. Turn the crankshaft in the normal direction of rotation of the engine until the inlet valve (valve No. 7) for the 4th cylinder has just opened and the exhaust valve (valve No. 8)for the same cylinder is not quite closed, that is the valves are "rocking". Check the clearance for valves 1 and 2 (cylinder 1). Adjust when necessary. Then check and adjust if necessary the clearance for valves 5 and 6 (cylinder 3). Figure 1 Position of valves in cylinder head. A. Direction towards rear of machine 2. Turn the crankshaft in the normal direction of rotation until valves 3 and 4 (cylinder 2) "are rocking". 3. Turn the crankshaft in the normal direction of rotation until valves 1 and 2 (cylinder 1) "are rocking". Then check/ adjust the clearance for valves 7 and 8 (cylinder 4). 4. Turn the crankshaft in the normal direction of rotation until valves 5 and 6 (cylinder 3) "are rocking". Then check/ adjust the clearance for valves 3 and 4 (cylinder 2). Figure 2 Valve sequence A = Cylinder number B = Valve number I = Inlet valve

Service Information Document Title: Crankshaft, description Function Group: 216 Information Type: Service Information Date: 2014/3/21 Profile: WLO, L50D [GB] Crankshaft, description Description The crankshaft is made of forged chrome molybdenum steel. It is carried in five main bearings. The end float is adjusted with thrust washers positioned on either side of the centre main bearing. All bearing journals are surface hardened and ground. Drilled ducts in the crankshaft provide supply of oil from the main bearings to the big-end bearings.

Service Information Document Title: Fuel specifications Function Group: 233 Information Type: Service Information Date: 2014/3/21 feed pump Profile: WLO, L50D [GB] Fuel feed pump specifications Fuel feed pump Type Feed pressure Diaphragm 100 200 kPa (1 2 bar) (15 29 psi)

Service Information Document Title: Fuel feed pump, checking feed pressure Function Group: 233 Information Type: Service Information Date: 2014/3/21 Profile: WLO, L50D [GB] Fuel feed pump, checking feed pressure Op nbr 23304 11666037 Hose 11666016 Pressure gauge (100 500 kPa) (1 5 bar) (14 73 psi) 13933686 Nipple 4881387 Nipple 4935151 Nipple The following applies when checking: Feed pressure: 100 200 kPa (1 2 bar) (15 29 psi) The check assumes that fuel can flow freely to the feed pump. 1. Disconnect the pressure line of the feed pump from the filter. Connect a pressure gauge according to the figure. NOTE! Do not tighten the joint between the pressure line and the nipple 4935151 before the line has been bled of air. Figure 1 1. 2. 3. 4. 5. 4935151 Nipple 4881387 Nipple 13933686 Nipple 11666037 Hose 11666016 Pressure gauge 2. Bleed the line by pumping with the hand pump until fuel free of air bubbles flows from the joint between the pressure line and nipple 4935151. Tighten down the pressure line nipple and make sure there are no leaks between the feed pump and the pressure gauge. 3. Disconnect the fuel injection stop solenoid, by detaching the electrical cable.

Figure 2 1. Stop solenoid 4. Run the starter motor for approx. 10 seconds. Read off the pressure. If the indicated max. pressure is lower than what is stated under "The following applies when checking" above, the fuel feed pump must be replaced with a new unit. The pump must also be replaced in cases where the indicated pressure drops to half in less than 30 seconds. 5. Remove the pressure gauge and other tools. Connect the pressure line to the filter. 6. Bleed the line by loosening the bleeder screw on the filter retainer and pump with the hand pump until fuel free from air flows out at the screw. Tighten the screw. 7. Reconnect the stop solenoid connector.

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

Service Information Document Title: Fuel system, bleeding Function Group: 233 Information Type: Service Information Date: 2014/3/21 Profile: WLO, L50D [GB] Fuel system, bleeding Op nbr 23301 1. Loosen the bleeder screw on top of the filter head. 2. Pump with the handle on the feed pump until fuel, free from air bubbles, flows out. Tighten the bleeder screw. NOTICE If it's not possible to pump with the handle on the feed pump, this is probably due to the drive cam for the feed pump standing at max. lift. Solve this problem by rotating the crankshaft one full turn. Figure 1 Feed pump 1. Hand pump 3. Loosen the nut for the pipe coupling by the fuel-powered cold-starting device and pump with the handle on the feed pump until fuel, free from air bubbles flows out by the pipe coupling. Tighten the nut. 4. Loosen the nut for the pipe coupling on the fuel supply pipe. Pump with the handle on the feed pump until fuel, free from air bubbles, flows out by the loosened pipe coupling. Tighten the coupling. 5. Loosen the delivery pipe connection by two of the injectors. 6. Crank with the starter motor until fuel, free from air, flows out by the delivery pipe connections. Tighten the connections. Tightening torque: 22 Nm (16 lbf ft). NOTE! Do not tighten the nut harder than the prescribed tightening torque, as overtightening may cause a constriction at the end of the pipe. The constriction may, in its turn, affect the amount of injected fuel. If a leak should occur at the delivery pipe connection later on, make sure that the pipe is pointing straight at the inlet on the injector.

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com