Volvo L35B Compact Wheel Loader Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

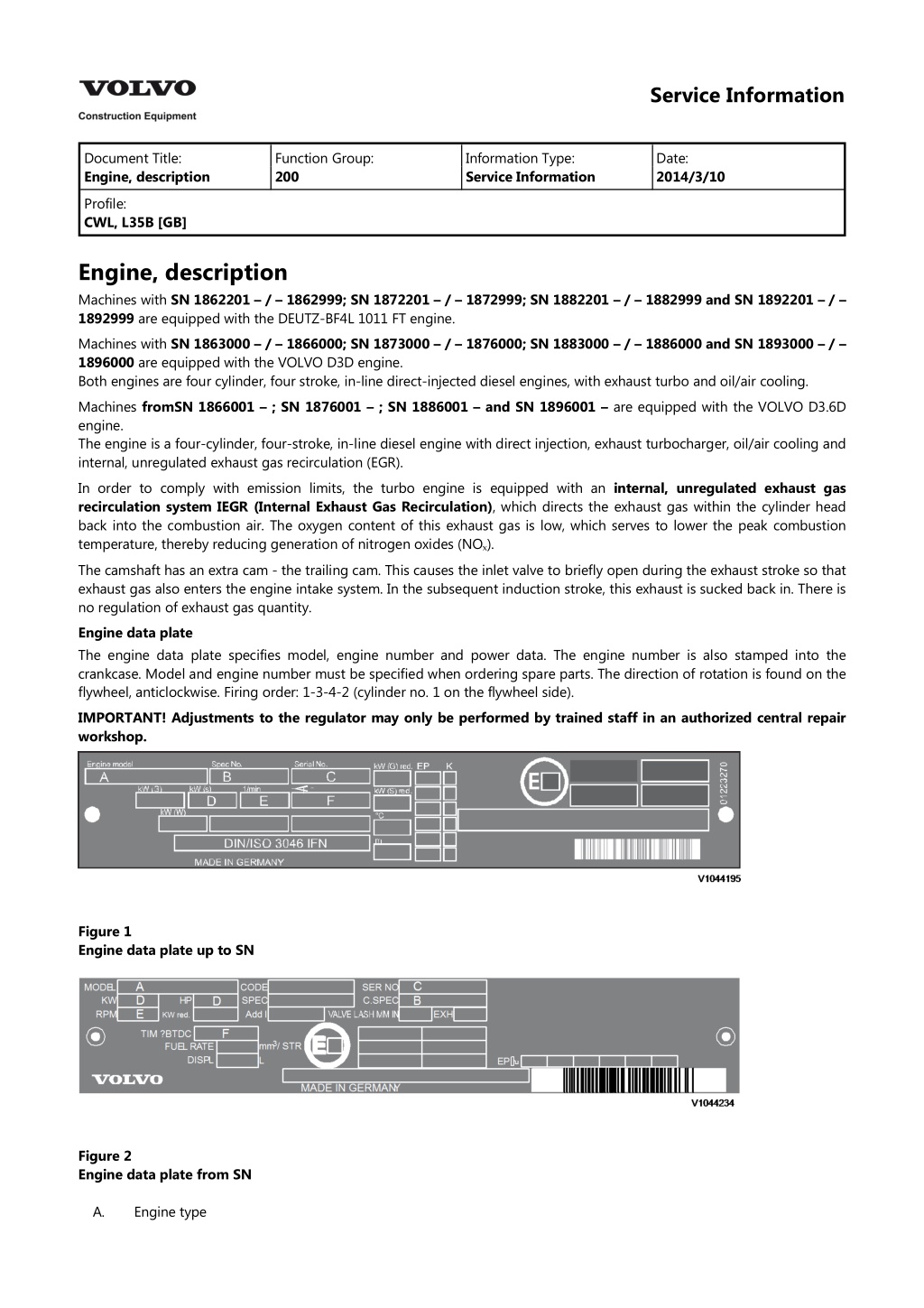

Service Information Document Title: Engine, description Function Group: 200 Information Type: Service Information Date: 2014/3/10 Profile: CWL, L35B [GB] Engine, description Machines with SN 1862201 / 1862999; SN 1872201 / 1872999; SN 1882201 / 1882999 and SN 1892201 / 1892999 are equipped with the DEUTZ-BF4L 1011 FT engine. Machines with SN 1863000 / 1866000; SN 1873000 / 1876000; SN 1883000 / 1886000 and SN 1893000 / 1896000 are equipped with the VOLVO D3D engine. Both engines are four cylinder, four stroke, in-line direct-injected diesel engines, with exhaust turbo and oil/air cooling. Machines fromSN 1866001 ; SN 1876001 ; SN 1886001 and SN 1896001 are equipped with the VOLVO D3.6D engine. The engine is a four-cylinder, four-stroke, in-line diesel engine with direct injection, exhaust turbocharger, oil/air cooling and internal, unregulated exhaust gas recirculation (EGR). In order to comply with emission limits, the turbo engine is equipped with an internal, unregulated exhaust gas recirculation system IEGR (Internal Exhaust Gas Recirculation), which directs the exhaust gas within the cylinder head back into the combustion air. The oxygen content of this exhaust gas is low, which serves to lower the peak combustion temperature, thereby reducing generation of nitrogen oxides (NO?). The camshaft has an extra cam - the trailing cam. This causes the inlet valve to briefly open during the exhaust stroke so that exhaust gas also enters the engine intake system. In the subsequent induction stroke, this exhaust is sucked back in. There is no regulation of exhaust gas quantity. Engine data plate The engine data plate specifies model, engine number and power data. The engine number is also stamped into the crankcase. Model and engine number must be specified when ordering spare parts. The direction of rotation is found on the flywheel, anticlockwise. Firing order: 1-3-4-2 (cylinder no. 1 on the flywheel side). IMPORTANT! Adjustments to the regulator may only be performed by trained staff in an authorized central repair workshop. Figure 1 Engine data plate up to SN Figure 2 Engine data plate from SN A. Engine type

B. C. D. E. F. Spare part number Engine number Capacity Rated speed Timing setting Components, servicing view Figure 3 Components, servicing view 1. 2. 3. 4. 5. 6. 7. 8. 9. Oil filler port (valve cover) Charge air line / Suction pipe Fan with integrated alternator V-rib belt Engine stop solenoid Gear housing cover, timing belt cover V-belt roller, crankshaft Oil sump Start/stop lever Engine speed adjustment Oil dipstick Oil filler pipe Fuel pump Fuel filter Boost pressure full-load stop Oil filter Cooling air baffle Injection pumps Oil cooler 10. 11. 12. 13. 14. 15. 16. 17. 18. 19.

Components, exhaust view Figure 4 Components, exhaust view 1. 2. 3. 4. 5. 6. 7. 8. 9. Cylinder head Exhaust manifold Flywheel Starter Turbocharger Lubrication oil line from exhaust turbocharger Lubrication oil line to exhaust turbocharger Inlet port Induction manifold Charge air measurement connection 10.

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

Service Information Document Title: Engine, removing Function Group: 210 Information Type: Service Information Date: 2014/3/10 Profile: CWL, L35B [GB] Engine, removing Op nbr 210-070 9998547 Lifting tool Lifting eye, x2 M12 1. Place the machine in service position. 2. Switch off the battery connection switch. WARNING The work involves handling heavy components - failure to stay alert may result in severe crushing injuries. Remove the engine hood. 3. Open the engine hood and unscrew the fixing bolts. 4. Lift off the engine hood and place it on a suitable surface. 5. Release clamp (1) on air filter intake hose and pull hose off air filter. Figure 1 6. Remove screw (2) from side bulkhead and remove complete with air filter. Remove rear counterweight.

7. Disconnect the pin plug connection of the tail lights. 8. Suspend the counterweight from a crane using suitable hoisting equipment. Figure 2 9. Remove the counterweight retaining bracket (arrows). Figure 3 10. Slowly raise the counterweight and remove towards the rear. NOTE! Lower the counterweight onto a suitable surface. 11. Suspend the hydraulic variable displacement pump from a crane using suitable hoisting equipment.

Figure 4 12. Unscrew the fixing bolts (arrows) of the hydraulic variable displacement pump. Pull the pump rearwards out of the connection flange and set it on the frame plate. 13. Remove air duct cover Figure 5 14. Undo the hose clamp with clamping tongs and detach the fuel return hose (1). Figure 6 NOTICE When a hose has been disconnected, plug both the hose and the connection immediately. The hoses should be marked for correct connection. 15. Detach the fuel lines (1) and (2) at the fuel filter/water separator.

Figure 7 16. Remove heater connections (1) and (2) with clamp (3). Figure 8 NOTE! Mark supply and return. 17. Detach the throttle cable from the engine. Unscrew the bracket (1) and slacken the jam nuts (2). Figure 9 18. Remove ground connection at engine block.

Figure 10 19. Detach preheating connection cable. Figure 11 20. Disconnect charging current line (B+) to starter. Figure 12 21. Disconnect the X26 electric pin plug connection.

Figure 13 NOTE! The engine plug X26 is on the starter side near the fan rotor 22. Remove the boost pump connection at the power take-off (PTO) and seal with a plug. Figure 14 23. Remove the flexi exhaust pipe from the turbocharger at the silencer. Figure 15 24. Screw in the lifting eyes and suspend the engine from the crane using the lifting yoke.

Figure 16 25. Remove engine bracket fixing bolts at frame. Figure 17 26. Slowly out the engine and place it on a suitable surface.

Service Information Document Title: Engine, installing Function Group: 210 Information Type: Service Information Date: 2014/3/10 Profile: CWL, L35B [GB] Engine, installing Op nbr 210-072 9998547 Lifting tool Lifting eye, x2 M12 WARNING The work involves handling heavy components - failure to stay alert may result in severe crushing injuries. 1. Screw in the lifting eyes and suspend the engine from the crane using the lifting yoke. Figure 1 2. Slowly lower the engine into the engine bay and position on the engine mounts. NOTICE Make sure that no hoses or cables are trapped.

Figure 2 3. Tighten the engine bracket fixing bolts to the frame. Tightening torque 200 Nm (148 lbf ft). 4. Unhook the lifting yoke and unscrew the lifting eyes. 5. Fit the flexi exhaust pipe to the turbocharger at the silencer. Figure 3 6. Connect the X26 electric pin plug connection. Figure 4 NOTE! The engine plug X26 is on the starter side near the fan rotor

7. Fit the boost pump connection to the power take-off (PTO). Figure 5 8. Connect the charging current line (B+) to the starter. Tightening torque 15 Nm (11 lbf ft). Figure 6 9. Attach preheating connection cable. Figure 7 10. Install ground connection at engine block.

Figure 8 11. Attach throttle cable to the engine. Fasten the bracket (1) and slacken approximately one turn. Tighten the jam nuts (2). Figure 9 NOTE! Depress the accelerator pedal all the way and check whether the engine speed adjustment level rests against the adjuster screw. 12. Install heater connections (1) and (2) with clamp (3). Figure 10 NOTE! Observe supply and return markings! 13. Attach the fuel lines (1) and (2) at the fuel filter/water separator.

Figure 11 14. Attach the fuel return hose (1) and fasten the hose clamp using clamping tongs. Figure 12 15. Install air duct cover Figure 13 16. Suspend the hydraulic variable displacement pump from a crane using suitable hoisting equipment and insert in the connection flange.

Figure 14 17. Screw in the fixing bolts (arrows) and tighten to 210 Nm (155 lbf ft). 18. Suspend the counterweight from a crane using suitable hoisting equipment and position it on the rear frame plate. Figure 15 19. Fit the counterweight retaining bracket (arrows) and tighten the fixing nuts to 210 Nm (155 lbf ft). Figure 16

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

20. Connect the pin plug connection of the tail lights. 21. Fit side bulkhead with air filter and tighten bolts (2). Figure 17 22. Fit the air filter intake hose and fasten it with the clamp (1). 23. Install the engine hood. 24. Check engine oil level 25. Switch on the battery disconnect switch. 26. Start the engine. After test running for a brief period (approx. 2 minutes at low idling speed), check the oil level and top up as necessary.

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com