Synthesis and Characterization of Titanium Carbide Nanofibers using Modified Carbothermal Reduction Process

Titanium carbide nanofibers were synthesized and characterized using a modified carbothermal reduction process. The process involved the use of ethanol/methanol mixture, polyvinyl-pyrrolidone, HNO3, and titanium isopropoxide. Various techniques were employed to achieve the desired nanofiber morphology and structure. Past work in the field of electrospinning and carbothermal carbon sources was also referenced. The synthesis process included steps such as carbon coating, propylene cracking, and heat treatments in controlled atmospheres. The resulting TiC nanofibers exhibited unique properties suitable for diverse applications.

Uploaded on Oct 04, 2024 | 3 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Synthesis and Characterization of Titanium Carbide Nanofibers Using a Modified Carbothermal Reduction Process Kanchan Mondal, Chung Ying Tsai Mechanical Engineering and Energy Processes Southern Illinois University, Carbondale, USA Materials Congress 2017 Rome, Italy June 12-14th, 2016

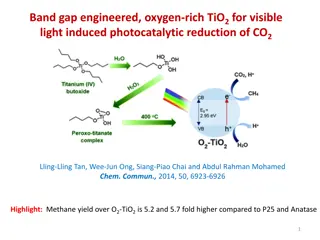

Background Carbothermal Process for TiC and TiB2 Powder Synthesis

Some Past Work Electrospinning and Carbothermal Carbon Source - Furfural Alcohol Zhang et al, Nanoscale, 2010, 2, 1670 1673 Taguchi et al, J. Phys. Chem. C, 2007, 111 In molten salts On nanoporous cotton fiber Li et al, C A R B ON , 2008, 4 6, 3 0 5 3 0 9 Li et al Cryst. Growth Des. 2011, 11, 3122 3129 Tao et al, Cryst. Growth Des. 2011, 11, 4422 4426

TiC Nanofibers Synthesis Ethanol/methanol mixture Polyvinyl- pyrrolidone HNO3 Titanium isopropoxide + + - - S y rin g e P u m p S y rin g e P u m p H ig h V o lta g e P o w e r S u p p ly 0 6 0 k V 6 o r 1 0 W 6 o r 1 0 W H ig h V o lta g e P o w e r S u p p ly 0 6 0 k V C o lle c to r C o lle c to r P la te o r ro ta tin g d is c P la te o r ro ta tin g d is c

TiC Nanofibers Synthesis TiO2 nanofiber As-spun Titanium fibers Polypropylene Carbon Black Powder/ Evaporarted C 600 C 50 psi Carbon Coated TiO2 nanofibers Heat Treatment 1300- 1500 C 1-4 Hrs Argon Atmosphere

1 D nano TiC Carbon Coating by Propylene Cracking

1 D nano TiC Carbon Coating by Evaporated Carbon

TiC Nanofibers As Spun Fibers Contained in Cellulose Paper

c a b Direct 1500 C 350C Then 1500 C 2 m 2 m As Spun 2 m e d f 500C Then 1400 C d) With 6hrs at With Cellulose paper 1400 C 400nm 400nm 400nm With Cellulose paper g 50nm

f e d c b

(111) 15-29nm 2.50 111 200 220 311 Interplanar spacing of 2.50

Titanium Carbide Fibers C B Lattice Parameter- 4.330 A B C Low Cost of Production Metallic Conductivity Pure TiC fibers Improved TiB2 sintering properties 10 % doping gave 97% theoretical density vs 94 % of pure TiB2 100- 200 nm diameter L/D >50

Conclusions Combination of two key factors contributed to the successful production of the continuous smooth TiC nanofiber with high purity: (1) Fine-tuned heat treatment parameter, and (2) External supply of carbon through pyrolysis of cellulose.. The TiC nanofibers exhibited a smooth surface morphology Length of the nanofibers were in the centimeter range, which makes the fibers suitable for a wide variety of applications Length of the nanofibers were in the centimeter range, which makes the fibers suitable for a wide variety of applications TiC nanofiber showed metallic behaviour TiC nanofiber matrix can be used as EDLC

![The Synthesis of Cedranoid Sesquiterpenes via Photo-Rearrangement of Bicyclo[2.2.2] Octenones](/thumb/198279/the-synthesis-of-cedranoid-sesquiterpenes-via-photo-rearrangement-of-bicyclo-2-2-2-octenones.jpg)