Post Seismic Bridge Inspection: Bearings Evaluation

This inspection involves assessing various components of a bridge to ensure structural integrity post-seismic activity. The focus is on checking bearings for issues like broken keeper bolts, tilted rockers, and cracked concrete under bearing pads. Steel rocker and pin bearings are inspected for potential problems, including spalling of concrete and moderate seat cracking. Evaluation also covers hinge seat spalling and missing/toppled rocker bearings. Images provide visual examples of these bearing issues.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Post Seismic Bridge Inspection Check Bearings Check Bearings

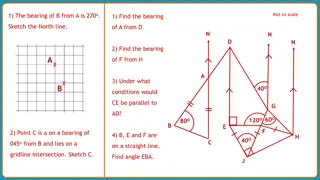

10 Steps of Assessment 10 Steps of Assessment 1. Check Approaches 2. Check Rails 3. Check Expansion Joints 4. Check Wingwalls 5. Check Abutments 6. Check Bearings 7. Check Girders 8. Check Soffit and Deck 9. Check Bents or Columns 10. Check Caps

Sixth Part Sixth Part Bearings Bearings Check Approaches 2. Check Rails 3. Check Expansion Joints 4. Check Wingwalls 5. Check Abutments 6. Check Bearings 7. Check Girders 8. Check Soffit and Deck 9. Check Bents or Columns 10. Check Caps 1.

6. Bearings 6. Bearings 2. 1. 2. 3 . 4 . 5 6 . . 6. Bearings broken keeper bolts, tilted rockers, cracked concrete under bearing pads

6. Bearings (contd) 6. Bearings (cont d) Steel Rocker Bearings Steel Rocker Bearings Tilted Rocker Bearing

6. Bearings (contd) 6. Bearings (cont d) Steel Bearings Steel Bearings Cracking under Masonry Plate

6. Bearings (contd) 6. Bearings (cont d) Steel Pin Bearings Steel Pin Bearings Minor Spalling of Concrete

6. Bearings (contd) 6. Bearings (cont d) Steel Pin Bearings Steel Pin Bearings Moderate Girder Seat Cracking and Spalling

6. Bearings (contd) 6. Bearings (cont d) Bearings at Hinge Seats Bearings at Hinge Seats Significant Hinge Seat Edge Spalling / Hinge Still Sound

6. Bearings (contd) 6. Bearings (cont d) Rocker Bearing Rocker Bearing Missing/Toppled Bearing Rocker/Span on Blocks

6. Bearings (contd) 6. Bearings (cont d) Rocker Bearings Rocker Bearings Failed Rocker Bearing / Damaged Bottom Flange

Exercise Exercise Fill out forms for the last bridge

STATE OF CALIFORNIA SAFETY ASSESSMENT PROGRAM BRIDGE Assessment Report No. _________

6. Bearings (contd) 6. Bearings (cont d) All Bearings All Bearings Bearings Failed and Cannot Confirm Load Path

6. Bearings (contd) 6. Bearings (cont d) Steel Pin Bearing and Others Steel Pin Bearing and Others Substantial Girder End Spalling above Bearing

6. Bearings (contd) 6. Bearings (cont d) Seat Loss Seat Loss Girder End Spalling & Loss of Seat