Panel Project – Auto-Identifying Cobot Applications

Discover how collaborative welding robots, or welding cobots, are revolutionizing industrial welding applications. These cobots provide a smaller-defined work envelope, eliminating the need for traditional robot safety cages. Welder/operators can work and collaborate safely with the system, improving productivity. They can handle various welding applications and are easier to use compared to complex automation.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

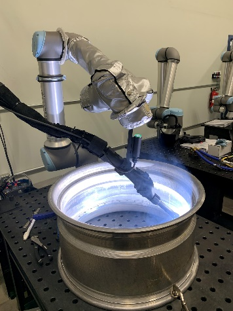

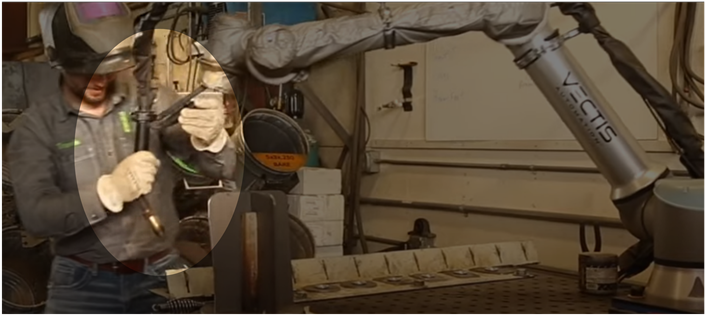

What is a Collaborative Welding Robot? Welding cobots are emerging as a viable solution for many industrial welding applications In its current state, it is a robotic welding tool with a smaller-defined work envelope that can be stationary or portable. It does not require traditional robot safety cages and allows personnel to work and collaborate with the system safely in close proximity. This enables welder/operators to fit and weld concurrently while the system is at work, greatly increasing productivity. Collaborative robotic welding systems are commercially available, production-tested and are easily taught to perform welding tasks without the need for traditional robot programming . The welder/operator grabs and manually positions the torch along weld lines and sets desired torch angles. They are untested for the rigorous requirements of shipbuilding. Cobot systems are much easier to use than highly complex automation, but still provide much of the flexibility and power of a larger scale industrial robot. They can handle a much broader set of welding applications compared to mechanized systems such as Bug-O s . Circles and complex shapes 2 Repetitive subassemblies Multipass stacking patterns and nonlinear joints In-process quality control as-needed

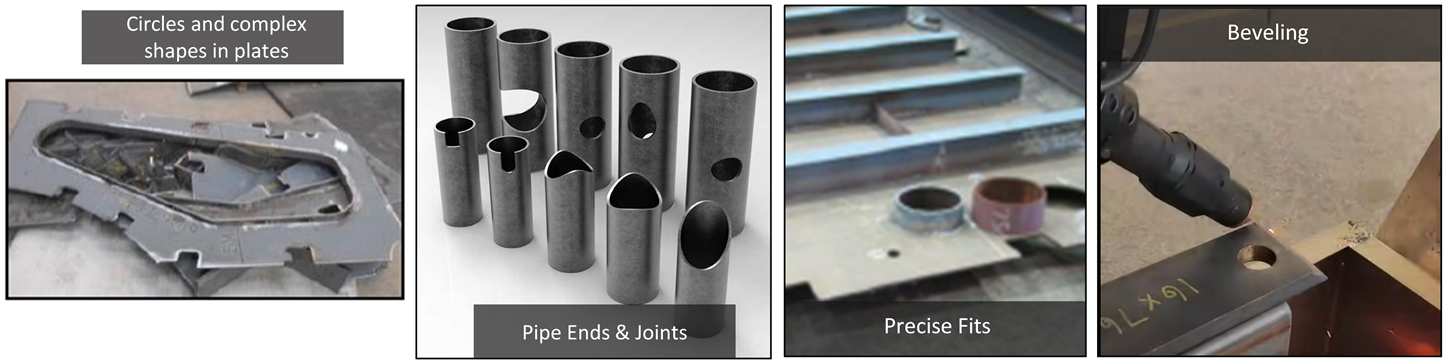

What is a Collaborative Cutting Robot? Welding cobots are emerging as a viable solution for many industrial welding applications In its current state, it is a robotic plasma cutting tool with a smaller-defined work envelope that can be stationary or portable. It does not require traditional robot safety cages and allows personnel to work and collaborate with the system safely in close proximity. This enables operators to prep and complete other tasks concurrently while the system is at work, greatly increasing productivity. Collaborative robotic cutting systems are commercially available, production-tested and are easily taught to perform cutting tasks without the need for traditional robot programming . The operator grabs and manually positions the torch along cut lines and sets desired bevel angles. Systems are easy to use and provide much greater cutting precision than manual cuts. Circles and complex shapes in plates Beveling They can handle a much broader set of cutting applications compared to mechanized systems such as Bug-O s . Precise Fits Pipe Ends & Joints 3

The Case for Collaborative Robotic Welding Arc Time of the Cobot Arc Time of the Welder Significant Increase in Work Force Productivity STRATEGY TO OFFSET WELDING LABOR SHORTAGES Allows a welder and a Cobot to weld simultaneously One can tack & fit components and the other can finish weld Welders and Cobots can work together on the same parts or different parts In many cases, their Combined Total Arc On time can more than double Cobots can be assigned to individual welders or to a group of welders and checked out when needed mobility allows them to move to the work Broad-Spread use of Cobots offers a strategy to reduce hiring & offset labor shortages 4

Cobot Welding is Similar to other forms of Mechanized Welding The Cobot Operator can safely monitor, inspect and dial in or adjust weld parameters to achieve desired specifications Emerging Collaborative Robotic Welding Traditional Accepted Buggo Welding Operator interaction can make weld qualification simpler 5

Outlining a Development Plan for the Auto-Identification of Cobot Welding and Cutting Applications within a Digital Ship Model 2022 Panel Project Submission 6

Committed to assisting with Cobot Technology Development for shipyard operations Engaged FMM Engineering, Manufacturing and FMG representatives in project scope development View this project as helping us to determine maximum benefit for shipbuilding operations Believe it will benefit the industry and NSRP Member Shipyards 7

Outlining a Development Plan for the Auto-Identification of Cobot Welding and Cutting Applications within a Digital Ship Model 2022 Panel Project Proposal PROJECT TEAM 8

Leveraging the digital model to assess Collaborative Robotic Welding & Cutting opportunities This project will focus on outlining a development plan so that potential cobot applications can be easily identified (at the design and production planning stages) from existing and potentially new information contained in and accessed directly from the 3D design and production models. The project will identify general information filtering strategies to help identify Cobot applications that can be leveraged to help ship designers design for cobot applications and production planners to plan for cobot applications . The project will also explore the relationships between information contained in the ERP System if necessary to close the identification loop. Potential Cobot Applications would then be validated before deployment. 9

Move Shipyards from Physical assessments for Cobot Welding opportunities to Digital Traditional Physical Assessments for applications are usually pocketed within the plant and limited to the knowledge of the assessor & a specific shop / need Model the Digital Assessment Strategy after the Physical Assessment Strategy Picture the ability to see these cobot welding applications the same way digitally that you do physically as a designer or production planner WELDING Specific Digital Filters Down-selection criteria for applications are always related to weld types according to technical feasibility, ROI, and organizational labor considerations. REDUCED SHIP COST

Move Shipyards from Physical assessments for Cobot Welding opportunities to Digital EXAMPLE WELDING Digital Filtering Criteria Plate size: x, y, z WELDING Specific Digital Filters Weld Type: Length of Weld: Formed / Flat: APPLICATIONS Multipass?: Etc ., Etc ..

Move Shipyards from Physical assessments for Cobot Cutting opportunities to Digital Traditional Physical Assessments for applications are usually pocketed within the plant and limited to the knowledge of the assessor & a specific shop / need Model the Digital Assessment Strategy after the Physical Assessment Strategy Picture the ability to see these cobot cutting applications the same way digitally that you do physically as a designer or production planner CUTTING Specific Digital Filters Down-selection criteria for applications involve technical feasibility, ROI, and organizational labor considerations. REDUCED SHIP COST

Move Shipyards from Physical assessments for Cobot Cutting opportunities to Digital EXAMPLE CUTTING Digital Filtering Criteria Plate size: x, y, z CUTTING Specific Digital Filters Aperture Shape: Surface Area of Opening: Formed / Flat: APPLICATIONS Beveled?: Etc ., Etc ..

Auto-Identification of Cobot Applications in Shipyards The Basic Project Timeline STAGE 1 - Develop a Generalized Digital Filtering Strategy to electronically identify Parts / Components for Cobot applications from the Digital Ship-Model. STAGE 2 - Assess SSI s Software Current State to support the Digital Filtering Strategies STAGE 3 - Document the Gap Summary Analysis for ShipConstructor software s Current State capabilities related to information requirements & filtering methods STAGE 4 - Propose high level strategies to close the digital information filtering gaps STAGE 5 - Summarize the inter-relationships between the ship design software, ship build software, and ERP software required to support the Digital Filtering Strategiesrf STAGE 6 - Provide a general development plan (and build graphical diagrams / renderings) for the auto-identification of cobot cutting and welding applications leveraging a Digital Ship-Model 2023 Panel Project Timeline 2nd Quarter 23 3rd Quarter 23 4th Quarter 23 STAGE 1 STAGES 2 & 3 STAGES 4 & 5 STAGE 6 Tech Transfer 14

Welding Cobot Application Videos Welding Off-Cart , Dual Zone 16

Welding Cobot Application Videos Multipass Stiffener Welds 17

Welding Cobot Application Videos Multipass Welding Interface 18

Welding Cobot Application Videos Circular Fillets 19

Welding Cobot Application Videos System Overview 20

Cutting Cobot Application Videos Piercing Beveling Coping Complex Shapes Profiles Cut to As-Built Trace and Cut 21