Fire Safety in Auto Repair Shops: Prevention and Preparedness

Auto repair shops face high fire risks due to the presence of flammable materials like volatile organic compounds. This material provides guidance on fire prevention plans, communication, training, fire suppression systems, emergency action plans, and identifying/mitigating fire hazards. Learn from a devastating shop fire incident and understand the importance of fire safety in auto repair shops.

Uploaded on Sep 15, 2024 | 80 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

FIRE SAFETY IN AUTO REPAIR SHOPS: FOR MANAGERS NOTHING ACTS FASTER THAN FIRE PREVENTION This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.

AGENDA Overview of a fire prevention plan Communication and training Fire suppression systems Emergency action plans Identifying and mitigating fire hazards in shop your This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 2

OVERVIEW OF A FIRE PREVENTION PLAN This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 3

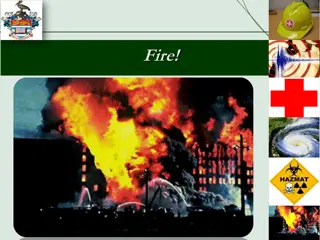

DEVASTATING SHOP FIRE November 2019, Lake Ronkonkoma, Long Island This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. endorsement by the U.S. Government. This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply

FIRE SAFETY IN AUTO REPAIR SHOPS This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not

VOLATILE ORGANIC COMPOUNDS (VOCs) Many shop products contain volatile organic compounds (VOCs) VOCs evaporate very easily and are very flammable VOCs are harmful to the environment because they cause the formation of ozone This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 6

ELEMENTS OF A FIRE PREVENTION PLAN 1. Have a written plan 2. Communicate the plan 3. Install fire warning and suppression equipment 4. Develop an emergency action plan 5. Evaluate the shop for fire hazards 6. Reduce or eliminate fire hazards This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 7

PART 1: HAVE A WRITTEN PLAN A fire prevention plan must be: In writing Kept in the workplace Made available to employees for review This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 8

PART 2: COMMUNICATION AND TRAINING This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 8

OSHA TRAINING REQUIREMENTS All aspects of the fire prevention plan Hazard Communication Standard to inform employees about the hazards of products they handle Personal protective equipment Hands-on fire extinguisher training This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 9

HAZARD COMMUNICATION STANDARD Safety data sheets contain valuable information about a product Manufacturers must create a safety data sheet for all of their products Employers must keep a safety data sheet on file for every product they use Employers must train their workers how to interpret the safety data sheets This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 10

16 SECTIONS OF A SAFETY DATA SHEET Section No. Information Section No. Information Identification Hazard identification Composition, ingredient information First-aid measures Fire-fighting measures Accidental release measures Handling and storage Exposure controls/personal protection Section 16 Physical and chemical properties Stability and reactivity Toxicological information Ecological information Disposal considerations Transport information Regulatory information* Other information Section 1 Section 2 Section 3 Section 4 Section 5 Section 6 Section 7 Section 8 Section 9 Section 10 Section 11 Section 12 Section 13 Section 14 Section 15 This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 11

PICTOGRAMS OR HAZARD SYMBOLS This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 12

PERSONAL PROTECTIVE EQUIPMENT (PPE) This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 13

PERSONAL PROTECTIVE EQUIPMENT PPE minimizes exposure to hazards that cause serious workplace injuries and illnesses Hazards include chemical, physical, electrical, and mechanical PPE includes gloves, safety glasses, shoes, protection, hard hats, respirators, coveralls, and vests This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 14

TYPES OF PPE Protection for eyes and face against chemical splashes, vapors, flying sparks and harmful glare Protection for hands against chemicals, sparks, heat, and sharp objects Protection for hearing protection against a loud environment Respirators protect workers lungs from hazardous airborne chemicals or particles If acids or bases are used, eyewash and showers providing 15 minutes of continuous flush must be available This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 15

PPE TRAINING When PPE is necessary What kind of PPE is necessary How to properly put PPE on, adjust, wear and take off The limitations of PPE Proper care, maintenance, useful life, and disposal This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 16

INVENTORY MANAGEMENT (1) Conduct an inventory of all the products in the shop Request missing safety data sheets from the vendor The product inventory will also be used for the fire hazard audit This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 17

INVENTORY MANAGEMENT (2) Order smaller containers of infrequently used materials Inspect shipments prior to acceptance for opened, damaged or leaking containers This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 18

PART 3: FIRE WARNING AND SUPPRESSION SYSTEMS This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 19

OSHA FIRE ALARM RECOMMENDATIONS Alarm system to alert shop staff to a fire emergency Alarm system to cover the entire shop The alarm can be voice communication (e.g., yelling Fire! or sound signals such as bells, whistles, or horns) This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 20

FIRE EXTINGUISHERS This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 21

TYPES OF FIRE EXTINGUISHERS This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 22

PART 4: PREPARE AN EMERGENCY ACTION PLAN Emergency procedures and escape routes Procedures for safely shutting down critical equipment Escape routes must be free of obstructions Locations of fire exits, fire extinguishers, and escape routes marked with signs This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 23

EMERGENCY ACTION PLAN Procedures for evacuating disabled employees Safe gathering place after evacuation Procedures to account for all shop employees and visitors quickly Emergency contact information for utilities, law enforcement and other key contacts This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 24

EMERGENCY ACTION PLAN EMPLOYEE TRAINING Train all employees in all aspects of the emergency action plan Alarm signal Evacuation route Equipment shutdown procedures Safe gathering place after evacuation Review plan with every new shop employee Communicate whenever the plan is changed This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 25

EVACUATION PLAN This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 26

PART 5: IDENTIFY AND MITIGATE FIRE HAZARDS This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 27

IDENTIFY SHOP FIRE HAZARDS Combustible materials such as paper Flammable liquids improperly stored, especially those containing VOC Ignition sources a) Engines and electrical equipment b) Space heaters c) Smoking Used shop rags stored improperly This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 28

MITIGATE SHOP FIRE HAZARDS (1) 1. Eliminate ignition sources 2. Store products containing VOC and other flammable products safely 3. Maintain a clean shop 4. Prevent spills 5. Clean up spills promptly This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 29

MITIGATE SHOP FIRE HAZARDS (2) 6. Handle wastes properly 7. Use water-based cleaners for degreasing and cleaning 8. Use a parts washer instead of flammable degreasers 9. Store used rags safely This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. 30

A SAFER AND MORE EFFICIENT SHOP This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government. This material was produced under grant number SH-99059-SH0 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not