Lean TQM (Total Quality Management) in Manufacturing

Lean TQM, originating post-WWII in Japan with Toyota's TPS, focuses on waste reduction, value creation, and continuous improvement in manufacturing processes. Key concepts include Kanban for visual progress tracking and eliminating Muda (waste) and Muri (overburden) to enhance productivity and efficiency.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Lean TQM (Lean Manufacturing) Origin Emerged in Japan post WWII, starting with Toyota Post WWII, Toyota shop floor engineer Taiichi Ohno rose through the ranks with the backing of Eiji Toyoda from the founding family, to install what became TPS (Toyota Production System), which in turn later became generally known as Lean Manufacturing. With the support of two US industrial engineers Meanwhile, two industrial engineering mavericks were flown into Japan at the request of the Union of Japanese Scientists and Engineers: W. Edwards Deming and Joseph Juran. In Japan, Deming s and Juran s teachings, overlapping but somewhat different in approach (Deming more a statistical approach, while Juran more focused on management), were immediately embraced since they first set foot on Japanese soil circa 1950. In the US, both of their work on quality management only came to mainstream attention in the late 80s when the concept of Lean Manufacturing started gaining recognition with the US auto manufacturers.

Lean TQM (Lean Manufacturing) Key concepts Reduction of waste Lean TQM is a systematic method for waste minimization ( Muda ) within a manufacturing system without sacrificing productivity. Value creation Lean TQM focuses on eliminating waste, but also on increasing the value the customer receives in order to create a competitive advantage. Value is defined as the actions or process steps that add value for the customer. Therefore, everything that is not value is waste. Continuous improvement Lean TQM encourages scientific methods of problem solving to improve processes and create flow for achieving high throughput (productivity). Rather than jumping to a solution, first the root cause of the problem is identified, solutions are developed and implemented, results are measured, and the process is repeated until optimal results are achieved.

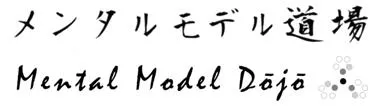

Lean TQM (Lean Manufacturing) Kanban Literally meaning board in Japanese, Kanban introduced the practice of making a team s progress of work openly visible to others on the floor. Kanban was adopted as a core concept in the later Lean Startup and Agile. And for good reason: you can see productivity increase apparent just having a Kanban board practice running, even before Scrum and Sprint routines are in place. The simple notion of persistent, visualized sharing of information; it s that powerful.

Lean TQM (Lean Manufacturing) Muda means waste Cutting out Muda is at the core of Lean, i.e. take out the fat (but some fat is good, i.e. slack more on this later). Making things that won t immediately sell, let alone sell anytime is an obvious Muda, but unnecessary processes, waiting time, idle inventory and even producing to over quality are all examples of Muda. So in Lean, just making a good product is not good enough. It needs to be produced in a way that is not wasteful. muda muda

Lean TQM (Lean Manufacturing) Muri means overburden Muri is more focused on process. This is where the concept of slack comes in counterintuitively, slack is good in Lean. When we think of slack, we think it is waste. So when we think of optimizing processes, our intuition is to cut out slack and try to make processes close to each other as much as possible. muri muri This is the number one cause of Muri, which results in bottlenecks. Processes need to be elastic, and slack is that elasticity. Hence, process optimization is all about how much slack to build in and adjust dynamically (of course, too much slack is Muda). On this topic, Eliyahu Goldratt s Goal is an awesome read.

Lean TQM (Lean Manufacturing) Mura means unevenness Mura is where Lean meets TQM (and all other stochastic processes of quality management including Six Sigma). Mura and Total Quality Management is not just about minimizing product defects, but also eliminating unevenness in processes (e.g. speed and volume). Heijunka ( ), meaning leveling of production, therefore, is a combined concept between elimination of Muri and Mura. mura mura

Lean TQM (Lean Manufacturing) Genchi-Genbutsu When an accident or failure happens, the first thing to do is to go to the Genchi, the actual place it happened, and look at the Genbutsu, the actual thing that broke or failed. As simple as that, in large organizations, even in Japan, head quarter managers still get caught in paralysis and fail to get their priorities right.

Lean TQM (Lean Manufacturing) Gemba Gemba has the same meaning as Genchi, i.e. the local place where things are happening. In Lean Manufacturing language, Gemba is used to teach the importance of respecting the line managers and floor workers they are the most intimate with the manufacturing process and most likely to be able to come up with continuous improvement ideas which some of them can leap frog to innovation.

Lean TQM (Lean Manufacturing) Kaizen The character for Kai means modification , Zen in this case means for better . There s a subtle difference to Kairyo ( ) which Ryo still means better . Kaizen has a connotation of smaller incremental improvement and more on behavioral improvements (i.e. better ways of doing things), while Kairyo hints functional improvements (i.e. on the product or manufacturing equipment). Kaizen is an encouragement for small improvements on a daily basis, hence synonymous to continuous improvement.

Lean TQM (Lean Manufacturing) Kakushin Think Sony Walkman. Kakushin means revolutionarily new, the punchy word for innovation in Japanese. (On a side note, Kakushin is an elusive slogan in Japanese organizations; conformity culture make workers great at Kaizen but leaves almost no space for the Einstein with the crazy idea to survive in a Japanese organization. The only reason why Sony s Walkman made it to the market, and the Honda Jet is flying today after decades of investment, is because the sponsors were the founders of the companies.)

Is Lean = efficiency? Anything wrong with these statements? 1. Our team is lean; we operate a tight ship and everybody multi-tasks. At what cost? If the quality of the team s work is sacrificed, is it the right thing to do? Cut us some slack! 2. We re going lean this quarter so let s cut expenses by 20% across the board. Where d that 20% come from? And expenses are one form of business investment, anything to say about that? Isn t there a better way of managing and finding ways to cut wasteful expenses? 3. You need to stick to the manual as our processes are lean and any deviation is a waste. Wait, so we re machine parts? What if we have suggestions for improvement in the process? Can t you let us be creative here?