Large Area Detectors Laboratory - June 8-12, 2015

A detailed overview of the Particle Physics Experiments and Laboratory Activities conducted at UNICAL in June 2015. The content includes information on detectors, laboratory setups, QAQC systems, gas distribution, and panel assembly for particle tracking.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

LARGE AREA DETECTORS LABORATORY JUNE 8-12, 2015 A. Mastroberardino, A. Policicchio, D. Salvatore, Marco Schioppa and P. Turco

2 08/06/15 UNICAL, LTL-2015 Particle Physics Experiments 1/3 The smaller the object to investigate the larger the apparatus to use: accelerators + detectors Crystallography Sub-Nuclear Physics source beam target beam targetdetector detector n = 2dsin

3 08/06/15 UNICAL, LTL-2015 Particle Physics Experiments 1/2 To take this kind of picture we need particle detectors with the following characteristics Radiation hard High spatial resolution Sensitivity to charge and neutral particles High time resolution Low cost

4 08/06/15 UNICAL, LTL-2015 Detectors Position (resolution better than 100um) Energy Momentum Time of flight (resolution better than 1ns) Trigger Selection of the interesting events Tracking Pattern recognition and reconstruction of the particle track

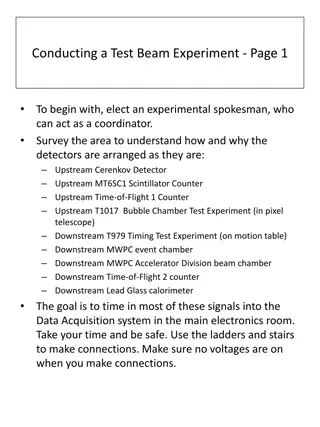

5 08/06/15 UNICAL, LTL-2015 Laboratory activity @ UNICAL 1/2 1. ATLAS upgrade Design, prototyping and construction of QAQC system with micrometers for the planarity of the drift panels (+/- 20um) and for the height of the drift panel internal frames (+/- 10um) QAQC system for the panels gas tightness Gas distribution system for the cosmic ray stand Monitor and control system of the assembling procedures of the micromegas chambers ITK

6 08/06/15 UNICAL, LTL-2015 An example: Micro Mesh Gas System Construction of the Drift panel Assembly scheme Drift ReadOut

7 08/06/15 UNICAL, LTL-2015 QAQC test stand table for panels Bosh Rexroth Aluminum Profile 45x90cm Threaded rods PART 1 PART 2 4.5x4.5 4.5x9 Threaded rods FRONT VIEW SIDE VIEW

8 08/06/15 UNICAL, LTL-2015 Drift/RO panel assembly into the vessel Vessel 1 Vessel 2 Table part 1 Table part 2 Vessel 1 is fixed to table structure part 1 Vessel 2 is fixed to table structure part 2 Drift or RO panel The two vessels and the drift/RO panel are screwed all together, as in the chamber assembly. Here the precision pins are not necessary. SIDE VIEW

9 08/06/15 UNICAL, LTL-2015 Gas tight test services Vessel 1: Differential pressure sensor (HCLA12X5EU 0-75mbar) Temperature sensor (LM35DZ) Gas inlet Gas outlet Vessel 2: Differential pressure sensor (HCLA12X5EU 0-75mbar) Temperature sensor (LM35DZ) Gas inlet Gas outlet Common services: Data acquisition system (FieldPoint of NI) Gas distributor TermoHigroBarometer for environment SIDE VIEW

10 08/06/15 UNICAL, LTL-2015 Gas tight panel test sequence Panel side 2: 1. Disconnect the services (gas inlet and outlet, differential pressure sensor, temperature sensor) to vessel 1 and leave these halls open 2. Connect the services to vessel 2 3. Fill the vessel 2 with compressed air, 5mbar over atmospheric pressure 4. Start recording the gas pressure in vessel 2 over 10 h Side 1 Side 2 Panel side 1: 1. Connect the services (gas inlet and outlet, differential pressure sensor, temperature sensor) to vessel 1 2. Don t connect the services to vessel 2 and leave them open 3. Fill the vessel 1 with compressed air, 5mbar over atmospheric pressure 4. Start recording the gas pressure in vessel 1 over 10 h Test duration: two days for RO panel and for central D panel one day for external D panel SIDE VIEW

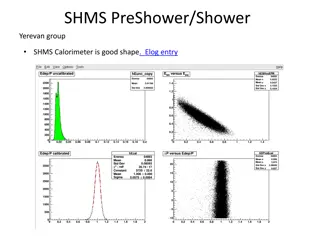

11 08/06/15 UNICAL, LTL-2015 Laboratory activity @ UNICAL 2/2 2. KLOE2 upgrade Design and construction of the cooling system of the QCALT calorimeter and its monitor and control

12 08/06/15 UNICAL, LTL-2015 Laboratory course Gaseous detector: RPC Construction of a 24x60cm single gap chamber Commissioning Test with cosmic rays