Innovative Fuel Technology by Cynar PLC: Converting Plastic Waste into Sustainable Fuels

Cynar PLC pioneers technology converting end-of-life plastics into synthetic liquid fuels, reducing landfill waste and greenhouse gas emissions. Seeking partners for future fuel development and renewable energy projects. Advanced discussions with potential collaborators. Opportunities to combine alternative fuels with biomass for enhanced energy output and environmental benefits. Visit www.cynarplc.com for more information.

Uploaded on Jul 18, 2024 | 5 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

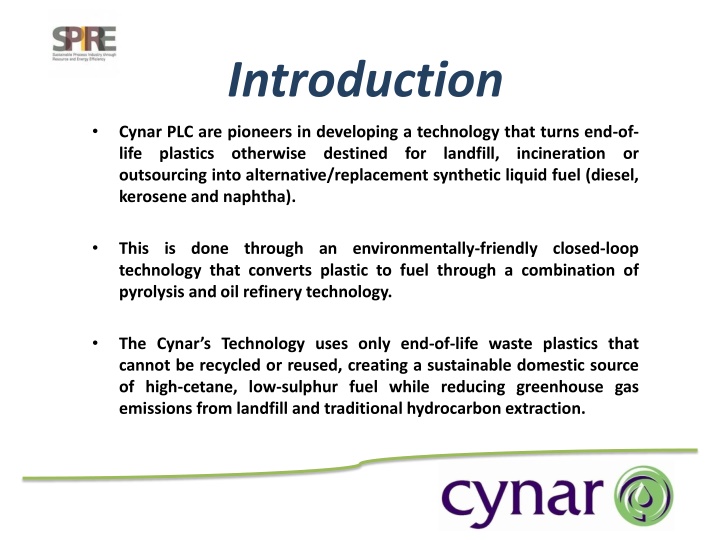

Introduction Cynar PLC are pioneers in developing a technology that turns end-of- life plastics otherwise destined outsourcing into alternative/replacement synthetic liquid fuel (diesel, kerosene and naphtha). for landfill, incineration or This is done through an environmentally-friendly closed-loop technology that converts plastic to fuel through a combination of pyrolysis and oil refinery technology. The Cynar s Technology uses only end-of-life waste plastics that cannot be recycled or reused, creating a sustainable domestic source of high-cetane, low-sulphur fuel while reducing greenhouse gas emissions from landfill and traditional hydrocarbon extraction.

SPIRE CALL 2 Seeking specialist partners to combine our Cynar waste plastics to fuels technology with biomass and residues to create future fuels, providing sustainable energy and process efficiency Cynar presently producing off and on-road diesel fuel from low grade plastic waste Cynar s alternative diesel capable of combining with renewable bio-diesel providing enhanced 1. Sustainability 2. Lower GHG 3. Cost benefits 4. Fuel & Environmental Security 5. Renewables utilisation Cynar has developed other usable fuels besides diesel capable of mixing with renewables biofuel and biomass creating - Enhanced energy output and calorific value - CHP Plant and Electrical Generation

Cynar is in advanced discussions with Parties interested in the development and deployment of alternative, sustainable and renewable fuel energy potentials These include- Irish Rail Carrier and Network operator International Shipping Owner EU Data Centre Owner Irish Transport Operator Cynar is seeking additional interested partners from these areas and from the process and chemical industry to advance our proposal

Cynar Consortium Requests Our alternative fuels combined with Biofuel and Biomass residuals offer wide potential in future - Energy generation and storage - Electrical generation and locomotion - New product and process development in Chemical Industry, Manufacturing, Processing and Food Production Next generation synthetic and biofuel combinations will - secure environmental and competitive advantages - create further innovation in renewables development - bring significant social and societal benefits We are looking for opportunities to partner with suitable colleagues for a consortium bid in SPIRE or other H2020 calls

Conclusion and Contact Details Thank You from the Cynar Team www.cynarplc.com