Hazard Communication in the Workplace

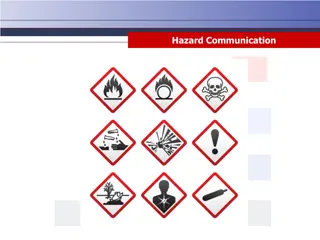

Employers must gather information on the hazards of chemicals they use and communicate this information to workers through training, labeling, and access to Safety Data Sheets (SDSs) as per OSHA Hazard Communication Standard (1910.1200). Hazard Communication Program (HCP) training covers chemical exposure, hazard identification, worker protection measures, and site-specific program details. Labels on chemical containers must include hazard warnings, and pictograms as of June 1, 2015. Clear labeling is essential in ensuring worker safety when handling hazardous substances.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

HAZ COM An employer must assemble information on the hazards of the chemicals they use. (Most will get this data from their chemical suppliers who are under OSHA mandate to supply the information.)

RICOSH OSHA Hazard Communication Standard (1910.1200) HAZCOMM, or HCS, or Right to Know.

HAZCOMM Employers are then required to establish a written program that communicates these hazards to their workers. HCP

HAZCOMM, Chemical hazards must be communicated to employees through the HAZCOMM triangle of a] training, b] labeling, and c] employee access to Safety Data Sheets [SDSs].

HCP Training must be performed prior to a job assignment or whenever a new chemical hazard is introduced into the work area. (A separate Rhode Island rule requires that this training be done annually.) HCP Training is to cover the following: Operations and work activities that involve exposure to chemical hazards How exposure can occur and how it can be minimized (e.g. precautions during handling and use) Explanation and identification of hazards of chemicals in the work area.

HCP Training must be performed prior to a job assignment or whenever a new chemical hazard is introduced into the work area. (A separate Rhode Island rule requires that this training be done annually.) . Measures adopted to protect workers. (engineering controls, work practices , PPE) Unforeseen hazards while performing non-routine tasks. Details of site s HCP program (e.g., labels and containers and connection to SDSs and HCP; how to read labels, and how to get a Safety Data Sheet).

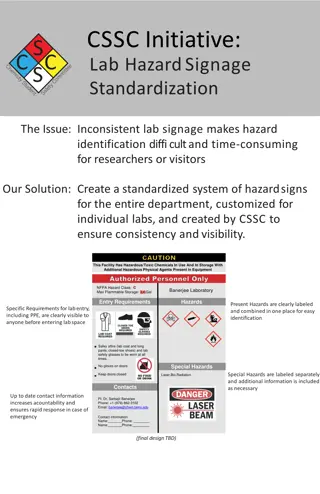

LABELS Labels. The HAZCOMM rule states that each hazardous chemical container must be labeled or tagged to identify the chemical, and include a hazard warning. (As of June 1, 2015, all labels will be required to have pictograms, a signal word, hazard and precautionary statements, the product identifier, and supplier identification. \

LABELS Labels should clearly identify the substance and hazards. If chemicals are in a process, sealed containers or pipes, then it is sufficient to post a placard or use a process sheet to inform those workers. (In cases where an employee transfers a substance from a labeled container to a smaller container for his/her own use, then the smaller container need not have a label).

SDS Safety Data Sheets. A cornerstone of all chemical hazard regulation is the Safety Data Sheet (the SDS). OSHA requires employers to obtain and maintain SDSs for chemicals they use.

SDS SDS> <Label> <Container in HCP Name of the substance (names of ingredient if a mixture) Physical and chemical characteristics Vp, flpt, vdensity,

New Labels Hazard Pictograms Signal Word Danger Hazard Statement Highly flammable liquid and vapor. May cause liver and kidney damage.

SDS Identification includes product identifier; manufacturer or distributor name, address, phone number; emergency phone number; recommended use; restrictions on use. Hazard(s) identification includes all hazards regarding the chemical; required label elements. Composition/information on ingredients includes information on chemical ingredients; trade secret claims.

SDS First-aid measures includes important symptoms/ effects, acute, delayed; required treatment. Fire-fighting measures lists suitable extinguishing techniques, equipment; chemical hazards from fire. Accidental release measures lists emergency procedures; protective equipment; proper methods of containment and cleanup.

SDS Handling and storage lists precautions for safe handling and storage, including incompatibilities. Exposure controls/personal protection lists OSHA's Permissible Exposure Limits (PELs); Threshold Limit Values (TLVs); appropriate engineering controls; personal protective equipment (PPE). Physical and chemical properties lists the chemical's characteristics.

SDS Stability and reactivity lists chemical stability and possibility of hazardous reactions. Toxicological information includes routes of exposure; related symptoms, acute and chronic effects; numerical measures of toxicity. Date the SDS was prepared or last revision.

SDS Under the OSHA Haz Comm rule employees have the right to examine and copy SDSs. SDSs are to be used by the employer in training and informing workers about chemical hazards.

SDS SDSs must be readily accessible during each work shift to employees when they are in their work area(s). (Electronic alternatives to paper safety data sheets are permitted as long as there are no barriers to immediate employee access.)

. OSHA has other rules that deal with chemical safety. Medical Access Standard (1910.1020) gives employees and physicians the right to review and copy records of records on chemical exposures. Confined Space (1910.146) directs employers to survey their facility for confined spaces where serious chemical hazards may pose a threat to anyone who enters that space. Employees not specifically trained and protected should not be allowed to enter such spaces. Emergency Response (1910.120) Employer must be prepared to respond to chemical emergencies.

OSHA has other rules that deal with chemical safety. Flammable and combustible liquids (1910.106)/Compressed gases (1910.101-105) regulate handling storage of chemicals. Process Safety Management (1910.119) In order to prevent accidental releases of highly hazardous chemicals chemicals employers must have a process safety plan. A process safety plan must contain information on these chemicals, as well on the technology and equipment involved in the process. Air containments (1910.1000) Exposure Limits

RICOSH James Celenza RI Committee on Occupational Safety and Health 741 Westminster st Prov RI 02903 751-2015 jascelenza@gmail.com Thank you for your attention This material was produced under grant number SH-26285-14-60-F- 37 from the Occupational Safety and Health Administration, U.S. Department of Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U.S. Government.