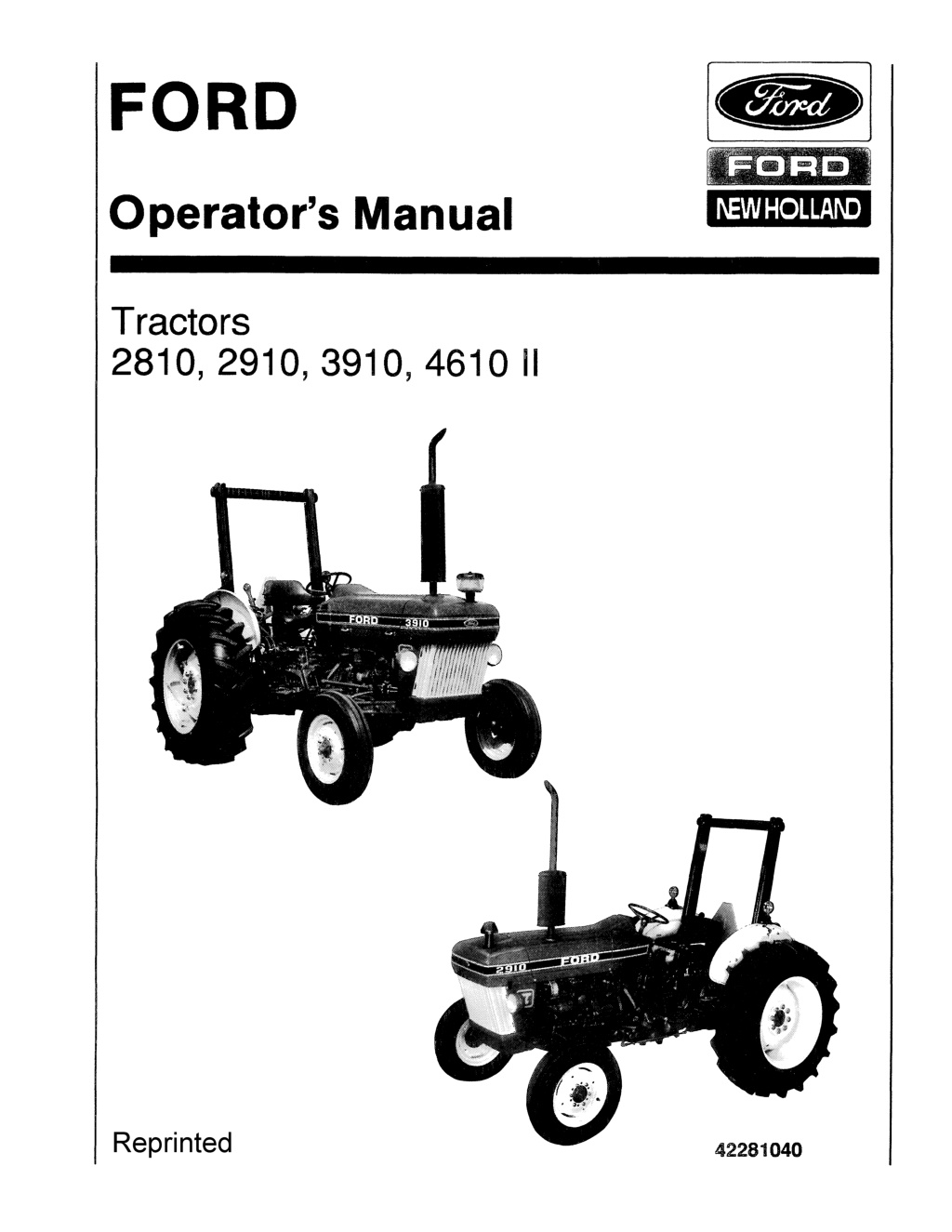

Ford New Holland 2810 2910 3910 4610 II Tractors Operator’s Manual Instant Download (Publication No.42281040)

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

FORD Operator's Manual I\EW HOllAI'D Tractors 2810,2910,3910,4610 II Reprinted 42281040

DEAR CUSTOMER - PLEASE READ CAREFULLY The warranty coverage that is extended to your Ford Tractor is explained in the Warranty and. Limitation of Liability, Ford Tractor form. Your dealer will provide you with a copy of the warranty and retain a copy which you have signed. After you read the warranty, ask your dealer to explain any points that you may not understand. Do not modify or alter or permit anyone else to modify or alter this tractor or any of its components or any tractor function without first consulting a Ford New Holland Dealer. H you have any questions regarding tractor modifications contact Ford New Holland, Inc., 2500 East Maple Road, Troy, Michigan 48084 A Roll Over Protective Structure (ROPS) and seat belt were standard equipment for the tractor at time of factory assembly. If the ROPS was deleted by the original purchaser or has been removed, it is recommended that you equip your tractor with a Roll Over Protective Structure (ROPS) and seat belt. ROPS safety cabs are effective in reducing injuries during tractor overturn accidents. Overturning a tractor without a ROPS or safety cab can result in serious injury or death. Roll Over Protective Structure (ROPS) safety cabs and seat belts are available for your Ford tractor. If your tractor is not equipped with a ROPS or safety cab and seat belt see your Ford New Holland Dealer. Your safety and the safety of those around you depends upon the care and good judgment you use while operating this equipment. Read the safety precautions carefully. For a complete list of the pre-delivery service checks performed by your dealer, refer to PRE-DELIVERY SERVICE on the upper portion of the following two pages. The first copy is your record of the service performed and the second copy, which is to be removed from the manual, is your dealer's record. MAKE SURE THAT YOU AND THE DEALER SIGN BOTH COPIES. After you have operated your tractor for fifty hours, take the manual and your tractor to your dealer. He will then perform the factory recommended 50-HOUR SERVICE as listed on the lower portion of the following two pages - without charge - except for lubricants, hydraulic oil, or filters replaced as part of normal maintenance. MAKE SURE THAT YOU AND THE DEALER SIGN BOTH COPIES. PARTS AND SERVICE CATALOGUES AVAILABLE! Ford New Holland is pleased to announce to owners of Ford tractors and equipment the availability of numerous parts and service catalogues. To obtain these catalogues merely fill out the order form available from your local authorised Ford New Holland Dealer. Mail with your remittance to Helm Inc. Your order will be processed promptly.

FORD 4610 FOUR CYLINDER ORCHARD TRACTOR OPERATOR'S MANUAL SUPPLEMENT GENERAL INFORMATION Depress the clutch and tum the key-start switch fully clockwise to position is), Figure 2. Operate the starting motor for a maximum of 60 seconds or until the engine starts, then allow the key to return to position (3). This supplement contains information on the Ford 4610 Orchard Tractor equipped with a fOUf cylinder engine. Use this supplement in conjunction with your Ford 2810, 2910, 3910 and 4610 Tractor Operator's Manual, SE 4216. Return the throttle to the idle position making sure that all warning lights are off and all gauges read normal. Read this supplement and your Ford Tractor Operator's Manual thoroughly before operating your new tractor and keep them both in a convenient location for future reference. cp I I ! I i I I I I CD I COLD WEATHER STARTING I I I I I In cold weather with the four cylinder engine cold without thermostart option: I I I I I When starting a cold engine at temperatures below 4QOF (40(:), open the hcmd throttle fully and depress the excess fuel button on the injection pump m, Figure 1. -----------0 NOTE: The excess fuel button will pop out when the engine starts. If the engine starts and then stops, depress the excess fuel button again before attempting to restart the engine. figure 2 Key-Start Switch 1. Electrical Equipment 4. Thermostart Heater "OFF" 2. Accessories "ON" 3. Warning lights and Accessories "ON" "ON" S. Starter Operates In cold weather with the engine cold and with ther- mostart installed: A installed, disconnect the terminal wire from the glow plug on the rear of the in- take manifold and insulate the free end of the wire. WARNING: Do not use ether with ther- most art. If, in an emergency, it is necessary to use ether with thermostart NOTE: The excess fuel button will pop out when the engine starts. If the engine starts and then stops, depress the excess fuel button again before attempting to restart the engine. figure 1 fuel Injection Pump 1. Excess Fuel Button 1

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

Depress the clutch and tum the key-start switch to the heat position (4). Figure 2. Hold fOf< 30 seconds then tum the key fully clockwise to start position (5). Crank the engine until it starts but do not operate the starter motor for more than 00 seconds. If the engine fails to start, repeat the pro- cedure, operating the thermostart for 30 seconds and the starting motor for up to 00 seconds. If the engine still fails to start, anow the battery to recover for 4 to 5 minutes, then repeat the procedure. EVERY 50 HOURS Fuel Injection Pump Oil level (Figure 4) Remove the level plug (2) to check the pump 011 level. If necessary f remove the filler engine oil. (1) and fill with clean When the engine starts, return the throttle to the idle position making SUfe that all warning lights are off and aU gauges read normal. LUBRICATION AND MAINTENANCE Follow the lubrication and maintenance chart in Operator's Manual SE 4216, with the following exceptions. Figure 4 EVERV 10 HOU RS Engine Oil Level (Figure 3) Fuel Injection Pump 1. Filler Plug 2. Level Plug Before checking the oil level, stop the engine and wait for a short period to allow the oil to drain back into the sump. Check the oil level with the dipstick (2}. If necessary, remove the filler cap (1) and add fresh oil of the recommended grade. See Section "C' of the Operator's Manual for the recommended grade of oiL EVERV 300 HOURS Engine Oil Change Warm the engine to operating temperature. Stop the engine, remove the drain plug (2), Figure 5, and catch the oil in a suitable container. Remove and discard the oil filter (1), Figure 5. Clean the face of the block and install a new filter. Do not overtighten the new filter.. Refill the engine with clean oil through the filler tube (1), Figure 6. Run the engine for a few minutes to cir- culate the oil. Allow the oil to drain back to the sump before checking the level with the dipstick (2), Figure 6. fUEL INJECTION PUMP Oil CHANGE (Figure 7) Drain the oil by removing the filler plug i1l, level plug (2) and drain plug (3). Install the drain plug and fill the pump with clean engine oil until it flows from the !eve! plug opening. Install the fJller plug and level plug. See Section "C" of Operator's Manual for recommended grade of 011. Same as engine oiL Figure 3 Engine Oil Level 1. Filler Cap 2. Dipstick 2

$21804 Figure 5 Figure 7 Engine Oil Drain and Filter 1. Oil Filter Fuel Injection Pump 2. Drain Plug 1. Filler Plug 2. Level Plug 3. Drain Plug EVERY 600 HOURS Valve Tappet Clearance (Figure 8) With the engine cold, remove the engine rocker cover and check valve tappet clearance as follows: Tum the crankshaft so that when any pair of valves shown in the chart below are fully open, the corresponding valves in the right column can be checked and adjusted. Valves Open No.1 into - 3 exh. No.3 int. - 4 exh. No. 2 exh. - 4 into No. 1 exh. - 2 into Valves to Adjust No. 1 into - 3 exh. No. 3 into - 4 exh. No. 2 exh. - 4 into No. 1 exh. - 2 int. Intake valve clearance 0.014 to 0.016 in. (cold) (0.36 to 0.4'1 mm). Exhaust valve clearance 0.017 to 0.019 in. (cold) \0.43 to 0.48 mm) Insert the feeler gauge (4) between each valve stem (3) and rocker arm (2). Tum the screw (1j to adjust the clearance. Figura 5 Engine Oil Filler Tube and Dipstick 1. Fmer Tube rocker cover using a new Replace the gasket. 2. Dipstick 3

Bleeding the fuel System 1. Filter Bleed Screw 2. 1. 2. Rocker Arm Screw 3. Valve Stem 4. Fee!er EVERY 2400 HOURS OR TWO YEARS Radiator Coolant BLEEDING THE FUEL SYSTEM {figure 9} the drain cock (1 L radiator. Remove the radiator cap to facHitate .. and drain the WARNING: WARNING: The system is Take care when .. Do not use your hand to check for leaks. Use a paper to search for leaks. the radiator cap when the of cardboard or pressure IMPORTANT: See ODt1rarWn 44 in your Manual before before lines. on the system. .. " " , \ . _ . t . " , ~ . _ all connections before cr::>rnrm the or Uft1S::iUn.UI WARNING: Inhibitor solution is irriJ"utitlr1 to eyes and skin. Contains buffered fines. 9.5. If any fluid is tention lmme'dj(;fte;rv or gangrene may result into the skin obtain medical at Avoid contact with eyes or and In case of contact, wash eyes, flush with water for 15 minutes and obtain medical attention. eyewear when Wash skin with soap and water after use. out of reach of children. Read and follow instructions on container< skin contact loosen the filter bleed screw i 1) and actuate the lever ;s from the bleed screw the bleed screw. until fuel free of air bubbles The with the stop control in and the throttle open until the starts. pump is Crank the

the drain cock \ 1 j, blode When both the radiator and 11, and drain the dose drain cocks and fin until normal n _ ' ~ ' ~ " M the "''''''H.'1',,.,,, tpn">n".r::>fHYt> is reached and drain a , . w c ' ~ r r . ! V C ' M tion of 50% Ford a n t i ~ f r e e z e and 50% dean water, ,","'V<H'''' fm the radiator the Figure 11 Engine Block Drain for coolant c a p a c ~ 1. Drain Cock and inhibitor maintenance schedule this GENERAL MAINTENANCE (Figure 12) Idle Speed Adjustment loosen the locknut !1l and tum screw idle the to IMPORTANT: The maximum no-load set by an authorized Ford New Hofland Dealer. must be 1, Locknut Radiator Drain 1, Drain Cock Screw

SPECI fiCA TIONS At each 2400 hour ""pnJ!I'P or every 2 yeats, whichever occurs first drain the block and by filling with clean water, engine to temperature and draining again. Then add one and a half bottle or 24 fluid ounces of inhibitor to the radiator and refiU WIth a"""",,""'''''''''' solution of 50% Ford anti freeze and 50% dean water. FOUR CYLINDER ENGINE then flush the the No. of Cylinders. . . . . . . . .. 4 Bore ...... " ............ 4.4 in. 011.8 mm} Stroke .................. 4.2 in. (106.7 mm) ............ 256 cu. in. (4186 cu. Compression Ratio ..... ,. 16.3:1 Firing Order. , ...... , ..... 1-3-4-2 Firing Idle Speed ..... , ... 600-850 rpm FUEL SYSTEM Rated Speed. , .... , 2100 rpm Maximum No-Load Speed. 2240 rpm Injection Pump , , .. ,. In-Une Tappet Clearance (Cold} Intake ........... , ...... 014-.016 (.36-.41 mm) Exhaust ................ 017-.019 (.43-.48 mm) CAPACITIES COOLING SYSTEM Cooling System .... , ... , . 27.0 U.S. Pints (0.5 bar) Pressure Cap ............ 7 22.4 Imp. Pts. 8.5 Litres COOLING SYSTEM INHIBITOR MAINTENANCE SCHEDULE Engine Oil Filter) .... 16.0 U.S. Pts. 13.2 Imp. Pts. At the first 50 hours only add 6 fluid ounces or Tnrpp.PlnnT<l of a bottle of in- hibitor to the radiator. 7.6 litres Engine Oil (With 18.0 U.S. Pte At each regular 300 hour service add 4 fluid ounces or a quarter bottle of inhibitor to the radiator. 15.0 Imp. Pts. 8.5 Litres

PRE-DELIVERY SERVICE - CHECK AND ADJUST AS REQUIRED iNOPERATIVE SERVICE CHECKS: 23. Front axle differential oil level (four wheel drive only) ............................. 0 24. Front axle hub oil level (four wheel drive only) ............................. 0 25. Check front weight clamp bolts for tig htness ................................................. 0 26. Check seat mounting and adjustment .................................................... 0 27. Front axle support bolts for tightness .... 0 28. Front axle spindle nuts for proper tig htness .......................................... 0 PERFORMANCE SERVICE CHECKS: 1. Tyre pressure ............................................... Ll 2. Air cleaner and hose connections ........... 0 3. Radiator coolant level ................................ Ll 4. Fan belt tension .... .......... . ........................ 0 5. Battery cleanliness, vent ()penings, electrolyte level, and specific gravity not less than 1.240 .................................... 0 6. Check all electrical cables and wire routings are away from sharp edges, moving parts and exhaust heat .. 0 7. Engine oillevel.. .......................................... 0 8. Transmission oil leveL ................................ 0 9. Rear axle oil level ....................................... Ll 10. Upper link, drawbar and pin in position ......................................................... 0 11. Power steering reservoir oil leveL .......... 0 12. Brake pedal free travel equalization and pedal lock ...................... 0 13. Clutch pedal free travel ............................. 0 14. Front wheel toe-in ..................................... 0 15. Front and rear wheel-to-rim clamp bolts and lock nuts for tightness ............. 0 16. Front and rear hub nuts and bolts for tightness ................................................. 0 17. Fuel level ...................................................... 0 18. Sheet metal and paint condition ............. 0 19. Lift rod levelling crank for proper operation ................................... D 20. Drain diesel fuel filter and water separator ....................................................... 0 21. Hydraulic lift Draft Control mainspring adjustment .............................. 0 22. Trailer brake reservoir oil leveL ............... 0 1. Engine operation including throttle and governor operation ............................. [.1 2. Transmission including clutch ................. [J 3. Steering controL....................................... [J 4. Differential lock engagement and disengagement ............................................ 0 5. Brake action ................................................ D 6. All optional equipment and accessories ................................................... 0 >- D-o u a: w -' w o OPERATIVE SERVICE CHECKS: All operative checks are to be performed with the tractor at normal operating temperature. 1. Lights and instruments for proper operation ......................................... 0 2. Fluid and oil leaks ...................................... 0 3. Diesel maximum no-load speed and idle speed adjustments and fuel shut-off ...... 0 4. Throttle linkage adjustment ...................... Ll 5. P.T.O. engagement and disengagement 0 6. Hydraulic System: Lift control levers for Draft and Position Control operation ................... 0 Flow control operation .......................... 0 Auxiliary service control or remote control valve ......................... 0 SAFETY ITEMS CHECKS: 1. ROPS installed ........................................... [J 2. Seat belts installed (with ROPS only) ... 0 3. P.T.O. master shield installed ................... 0 4. SMV emblem installed .............................. 0 5. Safety decals installed ............................... 0 6. Flashing lights/tail lights ........................... 0 7. Safety start switch operation .................... 0 8. Park brake and latch operation ................ 0 9. Operator's Manual ...................................... 0 INSPECTION PERFORMED WARRANTY EXPLAINED TRACTOR MODEL NO ........................ . TRACTOR SERIAL NO ................ . owner's signature date dealer's signature date --------------------x -------------------- 50-HOUR SERVICE - CHECK AND ADJUST AS REQUIRED INOPERATIVE SERVICE CHECKS: 19. Adjust valve clearances ......................... 0 PERFORMANCE SERVICE CHECKS: 20. Lubrication fittings and pivots . ........ 0 21. Check trailer brake oil reservoir ............ 0 22. Change front axle differential oil (four wheel drive only) ......................... 0 23. Change front axle hub oil (four wheel drive only) ...................... Ll 24. Front axle spindle nuts for proper tightness ...... ..... .......... . ...... .. r J 25. Check front weight clamp bolts for tightness ........................................ ' 1 1. Tyre pressure ........................................... 0 2. Air cleaner, pre cleaner and hose connections ................................... 0 3. Drain diesel fuel filter and water separator and bleed system ....... 0 4. Radiator coolant level/add inhibitor .... 0 5. All belt tensions ..................................... 0 6. Battery cleanliness and vent openings, electrolyte level, and specific gravity not less than 1.240 ................................ 0 7. Check all electrical cables and wire routings are away from sharp edges, moving parts and exhaust heat.. .......... 0 8. Drain and refill engine oil ..................... 0 9. Replace engine oil filter ........................ 0 10. Replace hydraulic oil filters .................. 0 11. Transmission oi1level ............................ 0 12. Rear axle oil leveL .................................. 0 13. Clutch pedal free travel ......................... D 14. Brake pedal free travel, equalization and pedal lock ........................................ 0 15. Steering gear box oil level ................... 0 16. Power steering reservoir oil level ......... 0 17. Front and rear wheel-to-rim clamp bolts and lock nuts for tightness ......... 0 18. Check front and rear hub nuts for tightness.. ...... .............. ...... 1. Engine operation including throttle and governor operation ........................ 0 2. Transmission including clutch ............. 0 3. Steering control. .. ..... ....... .. ..... . .......... 0 4. Differential lock engagement and disengagement ............................... . ..... 0 5. Brake action .................................... 0 6. All optional equipment and accessories ............................................. 0 ~ o u a: w -' ~ o OPERATIVE SERVICE CHECKS: 1. Lights and instruments for proper operation ................................... [J 2. Fluid and oil leaks .................................. 0 3. Diesel maximum no-load speed and idle speed adjustments and fuel shut-off ... 0 4. Throttle linkage adjustment ................. [J 5. Hydraulic System: Lift control levers for Draft and Position Control operation ................ [J Auxiliary service control or remote control valve ...................... L J SAFETY ITEMS CHECKS: 1. ROPS bolt torque ................................. [J 2. Seat belt condition and bolt torque .... 0 3. Safety start switch ............................... [J . ....... 0 WARRANTY EXPLAINED INSPECTION PERFORMED TRACTOR MODEL NO ........................ . TRACTOR SERIAL NO. owner's signature date dealer's signature date

PRE-DEILIVERY SERVICE - CHECK AND ADJUST AS REQUIRED HNOPIEIRA1WE SERVICE CHECKS: 23. Front axle differential oil level (four wheel drive only) ............................. 0 24. Front axle hub oil level (four wheel drive only) ............................. 0 25. Check front weight clamp bolts for tig htness ................................................ 0 26. Check seat mounting and adjustment .................................................... 0 27. Front axle support bolts for tightness .... 0 28. Front axle spindle nuts for proper tightness .......................................... 0 PERfORMANCE SERVICE CHIECKS: 1. Tyre pressure ............................................... 0 2. Air cleaner and hose connections ........... Ll 3. Radiator coolant level ................................ Ll 4. Fan belt tension .......................................... Ll 5. Battery cleanliness, vent openings, electrolyte level, and specific gravity not less than 1.240 .................................... 0 6. Check all electrical cables and wire routings are away from sharp edges, moving parts and exhaust heat .. 0 7. Engine oil leveL .......................................... 0 8. Transmission oil leveL ............................... 0 9. Rear axle oil level ....................................... 0 10. Upper link, drawbar and pin in position ......................................................... 0 11. Power steering reservoir oil level... .......... 0 12. Brake pedal free travel equalization and pedal lock ...................... Ll 13. Clutch pedal free travel ............................. 0 14. Front wheel toe-in ..................................... 0 15. Front and rear wheel-to-rim clamp bolts and lock nuts for tightness ............. 0 16. Front and rear hub nuts and bolts for tightness ................................................. 0 17. Fuel level ...................................................... 0 18. Sheet metal and paint condition ............. 0 19. Lift rod levelling crank for proper operation ................................... 0 20. Drain diesel fuel filter and water separator ....................................................... 0 21. Hydraulic lift Draft Control mainspring adjustment .............................. 0 22. Trailer brake reservoir oil level... ............... 0 1. Engine operation including throttle and governor operation.. ................. .. .. [J 2. Transmission including clutoh ......... . .. ~ I 3. Steering control.. .......... .. ................ ... . 0 4. Differential lock engagement and disengagement.. ...................................... IJ 5. Brake action .............................. ........ ....... . n 6. All optional equipment and accessories ................................................... 0 OPERATIVE SERVICE CHECKS: All operative checks are to be performed with the tractor at normal operating temperature. 1. Lights and instruments for proper operation ......................................... 0 2. Fluid and oil leaks ...................................... 0 3. Diesel maximum n o ~ l o a d speed and idle speed adjustments and fuel shut-off ...... D 4. Throttle linkage adjustment ...................... 0 5. P.T.O. engagement and disengagement 0 6. Hydraulic System: Lift control levers for Draft and Position Control operation ................... 0 Flow control operation .......................... 0 Auxiliary service control or remote control valve ......................... 0 SAFETY ITEMS CHECKS: 1. ROPS installed ............................................ 0 2. Seat belts installed (with ROPS only) ... 0 3. P.T.O. master shield installed .................. 0 4. SMV emblem installed ............................. 0 5. Safety decals installed ............................... 0 6. Flashing lights/tail lights .......................... 0 7. Safety start switch operation .................... 0 8. Park brake and latch operation ................ 0 9. Operator's ManuaL ..................................... 0 WARRANTY EXPLAINED TRACTOR MODEL NO ........................ . TRACTOR SERIAL NO ................ . INSPECTION PERFORMED date dealer's signature owner's signature date 50-HOUR SERVICE - CHECK AND ADJUST AS REQUIRED INOPERATIVE SERVICE CHECKS: 19. Adjust valve clearances ......................... 0 PERFORMANCE SERVICE CHECKS: 20. Lubrication fittings and pivots ............. 0 21. Check trailer brake oil reservoir. ........... 0 22. Change front axle differential oil (four wheel drive only) ......................... 0 23. Change front axle hub oil (four wheel drive only) ......................... 0 24. Front axle spindle nuts for proper tightness ..................................... 0 25. Check front weight clamp bolts for tig htness ...................................... , ..... Ll 1. Tyre pressure ........................................... 0 2. Air cleaner, pre cleaner and hose connections ................................... 0 3. Drain diesel fuel filter and water separator and bleed system ....... 0 4. Radiator coolant level/add inhibitor .... 0 5. All belt tensions ..................................... 0 6. Battery cleanliness and vent openings, electrolyte level, and specific gravity not less than 1.240 ................................ 0 7. Check all electrical cables and wire routings are away from sharp edges, moving parts and exhaust heat ............ 0 8. Drain and refill engine oil ..................... 0 9. Replace engine oil filter ........................ 0 10. Replace hydraulic oil filters .................. 0 11. Transmission oil level ............................ 0 12. Rear axle oil leveL .................................. 0 13. Clutch pedal free travel ......................... 0 14. Brake pedal free travel. equalization and pedal lock ........................................ 0 15. Steering gear box oil level .................... 0 16. Power steering reservoir oil level ......... 0 17. Front and rear wheel-to-rim clamp bolts and lock nuts for tightness ......... 0 18. Check front and rear hub nuts for tightness ............................................ 0 1. Engine operation including throttle and governor operation ......................... 0 2. Transmission including clutch ............. 0 3. Steering controL ..................................... 0 4. Differential lock engagement and disengagement ....................................... 0 5. Brake action ............................................ 0 6. All optional equipment and accessories " ............................................ 0 OPERATIVE SERVICE CHECKS: 1. Lights and instruments for proper operation ..................................... 0 2. Fluid and oil leaks .................................. 0 3. Diesel maximum no-load speed and idle speed adjustments and fuel shut-off ... 0 4. Throttle linkage adjustment .................. 0 5. Hydraulic System: Lift control levers for Draft and Position Control operation ................ 0 Auxiliary service control or remote control valve ...................... 0 SAFETY ITEMS CHECKS: 1. ROPS bolt torque .................................. 0 2. Seat belt condition and bolt torque .... 0 3. Safety start switch ................................. 0 WARRANTY EXPLAINED TRACTOR MODEL NO ........................ . TRACTOR SERIAL NO. INSPECTION PERFORMED date dealer's signature date owner's signature

FOREWORD This Manual has been prepared to assist you in the correct procedure for running-in, operation and maintenance of your new Ford Tractor. The Manual also covers various derivative models such as Vineyard, Narrow, Narrow Orchard, S.u. and L.c.G. tractors. These tractors carry the same model numbers as the All-purpose versions from which they derive. The Narrow and Vineyard tractors are of reduced width for operation between rows of crops such as fruit trees and vines. The Vineyard tractor, due to the considerable width reduction, has a unique seat and some modified controls. The Narrow Orchard tractor is identical to the Narrow tractor except for modified mudguards, lower and wider front axle and unique wheels and tyres as standard fitrnents. The two latter items affect some dimensional specifications of the tractor. Except where these differences occur, Narrow Orchard tractors are not specifically mentioned. The Ford 4610 S.u. tractor (Special Utility) has category I three-pOint linkage and a swept back front axle, as fitted to Ford 3910 tractors. DimenSionally, the tractor is the same as a Ford 3910 all-purpose. L.c.G. tractors have a low centre of gravity, achieved by means of shorter front wheel steering spindles and smaller rear wheels. Again, except where dimensional specifications differ, these models are not specifically mentioned. Read this Manual carefully and keep it in a convenient place for future reference. If at any time you require advice concerning your tractor, do not hesitate to contact your authorised Ford New Holland dealer. He has factory trained personnel, genuine Ford parts and the necessary equipment to carry out your service requirements. A vehicle identification plate is located under the tractor hood or low down on the right-hand side of the instrument console. If your tractor is equipped with four wheel drive transmission, then a similar plate is affixed to the rear of the front axle casing. For convenience, the numbers shown on the plates should be recorded in the panels below and quoted to your Ford New Holland dealer should the tractor require service. 0 O AXLE TYPE SERIAL NUMBER I L-I ___ ----'I ~ REF. NUMBER ~ - - - - - - - - ~ I ~ I ________ ~ INPUT ROT. - = ~ ____ ~ I I L ~ OIL SPECIFIC = = = = I C ~ I TOTAL RATIO OIFF. TYPE __ ~ LIT. J ~ = = ~ LOCATION ~ I D=IF=F. ==! ~ ICJ 1 EPIC. OL-I ______ ---"10 Front Axle Identification Plate Vehicle Identification Plate Ford New Holland policy is one of continuous improvement, and the right to change prices, specification or equipment at any time without notice is reserved. All data given in this book is subject to production variations. Dimensions and weights are approximate only and the illustrations do not necessarily show tractors in standard condition. For exact information about any particular tractor please consult your Ford New Holland dealer. (i)

SAFETY PRECAUTIONS A careful operator is the best operator. Most accidents can be avoided by observing certain precautions. To help prevent accidents read and take the following precautions before operating the tractor. Equipment should be operated only by those who are responsible and instructed to do so. 8. The fuel oil in the injection system is under high pressure and can penetrate the skin. Unqualified persons should not remove or attempt to adjust a pump, injector, nozzle or any other part of the fuel injection system. Failure to follow these instructions can result in serious injury. THE TRACTOR 1. Read the Operator's Manual carefully before using the tractor. Lack of operating knowledge can lead to accidents. 2. If your tractor is equipped with a RaPS or safety cab, use an approved Seat Belt for safe operation. Overturning a tractor can result in death or injury. If your tractor is not equipped with a seat belt, see your Ford New Holland Dealer. 9. Continuous long term contact with used engine oil may cause skin cancer. Avoid prolonged contact with used engine oil. Wash skin promptly with soap and water. 10. Some components on your tractor, such as gaskets and friction surfaces (brake linings, clutch linings, etc), may contain asbestos. Breathing asbestos dust is dangerous to your health. You are therefore advised to have any maintenance or repair operations on such components carried out by an authorised Ford New Holland dealer. If, however, service operations are to be undertaken on parts that contain asbestos, the essential precautions listed below must be observed: Work out of doors or in a well ventilated area. Dust found on the tractor or produced during work on the tractor should be removed by extraction not by blowing. Dust waste should be dampened, placed in a sealed container and marked to ensure safe disposal. If any cutting, drilling, etc., is attempted on materials containing asbestos, the item should be dampened and only hand tools or low speed power tools used. 3. If a front end loader is to be installed, always use a FOPS canopy to avoid injury from falling objects. 4. Use the handholds and step plates when getting on and off the tractor to prevent falls. Keep steps and platform cleared of mud and debris. 5. Do not permit anyone but the operator to ride on the tractor. There is no safe place for extra riders. 6. Replace all missing, illegible, or damaged safety decals. 7. Keep safety decals clean of dirt and grime. SERVICING THE TRACTOR 1. The cooling system operates under pressure which is controlled by the radiator cap. It is dangerous to remove the cap while the system is hot. Always tum the cap slowly to the first stop and allow the pressure to escape before removing the cap entirely. OPERATING THE TRACTOR 1. Apply the parking brake, place the P.T.O. lever in the "OFF" position, the lift control lever in the down position, the remote control valve levers in the neutral position, and the transmission in neutral before starting the tractor. 2. Do not smoke while refueling the tractor. Keep any type of open flame away. Wait for the engine to cool before refueling. 3. Keep the tractor and equipment, particularly brakes and steering, maintained in a reliable and satisfactory condi- tion to ensure your safety and comply with legal requirements. 2. Do not start the engine or operate controls while standing beside the tractor. Always sit in the tractor seat when starting the engine or operating the controls. 3. Do not bypass the neutral start switch. Consult your Ford New Holland dealer if your safety start controls malfunction. Use jumper cables only in the recom- mended manner. Improper use can result in a tractor runaway. 4. To prevent fires or explosions keep open flames away from battery or cold weather starting aids. To prevent sparks which could cause explosion use jumper cables according to instructions. 5. Stop the engine before performing any service on the tractor. 4. Avoid accidental contact with the gear shift lever while the engine is running. Unexpected tractor movement can result from such contact. 6. Escaping hydraulic/diesel fluid under pressure can penetrate the skin causing serious injury. DO NOT use your hand to check for leaks. Use a piece of cardboard or paper to search for leaks. Stop the engine and relieve pressure before connec- ting or disconnecting lines. Tighten all connections before starting the engine or pressurizing lines. If fluid is injected into the skin obtain medical attention immediately or gangrene may result. 5. Do not get off the tractor while it is in motion. 6. Shut off the engine and apply the parking brake before getting off the tractor. 7. Do not park the tractor on a steep incline. 8. Do not operate the tractor engine in an enclosed building without adequate ventilation. Exhaust fumes can cause death. 7. Do not modify or alter or permit anyone else to modify or alter this tractor or any of its components or any tractor function without first consulting a Ford New Holland dealer. 9. If the power steering or engine ceases operating, stop the tractor immediately. (ii)

SAFETY PRECAUTIONS OPERATING THE TRACTOR (Continued) 3. When operating stationary P.T.O. driven equipment, always apply the tractor parking brake and block the rear wheels front and back 4. To avoid injUly, do not clean, adjust, unclog or service P.TO. driven equipment when the tractor engine is running. S. Make sure the P.T.0. guard is in position at all times and always replace the P.TO. cap when the P.TO. is not in use. 10 Pull only from the swinging drawbar or the lower link drawbar in the down position. Use only a drawbar pin that locks in place. Pulling from the tractor rear axle or any point above the axle may cause the tractor to upset. 11. If the front end of the tractor tends to rise when heavy implements are attached to the three-point hitch, install front end or front wheel Weights. Do not operate the tractor with a light front end. DIESEL FUEL 1. Under no circumstances should gasoline, alcohol or blended fuels be added to diesel fuel. These combi- nations can create an increased fire or explosive hazard. In a closed container such as a fuel tank such blends are more explosive than pure gasoline. Do not use these b l e n d s ~ 12. Always set the hydraulic selector lever in position control when attaching equipment and when transporting equipment. Be sure hydraulic couplers are properly mounted and will disconnect safely in case of accidental detachment of implement. 13. Do not leave equipment in the raised position. 2. Never remove the fuel cap or refuel with the engine running or hot. 3. Do not smoke while refueling or when standing near fuel. 4. Maintain control of the fuel filler pipe nozzle when filling the tank S. Do not fill the fuel tank to capacity. Allow room for expansion. 6. Wipe up spilled fuel immediately. 7. Always tighten the fuel tank cap securely. 8. If the original fuel tank cap is lost, replace it with a Ford New Holland approved cap. A non-approved, proprie- talY cap may not be safe. 9. Keep equipment clean and properly maintained. 10. Do not drive equipment near open fires. 11. Never use fuel for cleaning purposes. 12. Arrange fuel purchases so that winter grade fuels are not held over and used in the spring. DRIVING THE TRACTOR 1. Watch where you are going especially at row ends, on roads, around trees and low hanging obstacles. 2. To avoid upsets drive the tractor with care and at speeds compatible with safety, especially when operating over rough ground, when crOSSing ditches or slopes, and when turning comers. 3. To provide two wheel braking lock the tractor brake pedals when transporting on roads. 4. Keep the tractor in the same gear when going downhill as used when going uphill. Do not coast or free wheel down hills. s. Any towed vehicle whose total weight exceeds that of the towing tractor must be equipped with brakes for safe operation. 6. When the tractor is stuck or tyres are frozen to the ground, reverse the tractor to prevent overturning. SAFETY FRAME (ROPS) If your Ford tractor is equipped with a safety frame it must be maintained in a serviceable condition. Be careful when driving through doorways or working in confined spaces with low headroom. Under no circumstances: 1. - - - modify, drill or alter the safety frame in any way as doing so could render you liable to legal prosecution. 2. - - - attempt to straighten or weld any part of the main frame or retaining brackets which have suffered damage. By doing so you may weaken the structure and endanger your safety. 3. - - - secure any parts on the main frame or attach your safety frame with other than the special high tensile bolts and nuts specified. 4. --- attach chains or ropes to the main frame for pulling purposes. 7. Always check overhead clearance, especially when transporting the tractor. 8. Dip the tractor lights when meeting a vehicle at night. Make sure the lights are adjusted to prevent blinding an oncoming vehicle operator. 9. North America only: Use the Flasher/Tum Signal lights and SMV sign when travelling on public roads, both day and night, unless prohibited by law. OPERATING THE P.T.O. 1. When operating P.T.O. driven equipment, shut off the engine and wait until the P.TO. stops before getting off the tractor and disconnecting the equipment. 2. Do not wear loose clothing when operating the power take-off or when near rotating eqUipment. S. - - - take unneces5aIY risks even though your safety frame affords you the maximum protection possible. Whenever you see this symbol A it means: ATTENTION! BECOME ALERT! YOUR SAFElY IS INVOLVED! (iii)

ROPS (North America only) ROLL OVER PROTECTIVE STRUC- TURES ROPS INSPECTION MAINTENANCE AND After the first 20 hours of operation and after every 300 hours of operation, or six months, whichever comes first; A roll over protective structure (ROPS) and seat belt were standard equipment for the tractor at time of factory assembiy. The seat belt, when used by the operator, maximizes the protection offered by the ROPS. ALWAYS use your seat belt when the ROPS is installed - seat belts save lives when they are used. Do not use your seat belt when the ROPS is not installed on the tractor. 1. Check the torque of the ROPS mounting bolts. Tighten, if necessary, to 180 - 220 lbf.ft. (25-30 kgf/m) (244-298 Nm). 2. Check the operator's seat mounting bolts and the seat belt mounting parts. Tighten bolts to torque and replace worn or damaged parts. If the ROPS was deleted by the original purchaser or has been removed, it is recommended that you equip your tractor with a roll over protective structure and seat belt. ROPS are effective in reducing injuries during tractor overturn acci- dents. Overturning a tractor without a ROPS can result in serious injury or death. DAMAGE TO THE ROPS A Roll Over Protective Structure and seat belts are available from your Ford New Holland Dealer. If the tractor has rolled over or the ROPS has been damaged (such as striking an overhead object during transport), the ROPS must be replaced to provide the original amount of protection. FALLING STRUCTURES (FOPS) OBJECT PROTECTIVE After an aCCident, check for damage to the (1) ROPS, (2) operator's seat, (3) seat belt and seat belt mountings. Before you operate the tractor, replace all damaged parts. When tractors are equipped with front-end load- ers and are not equipped with safety cabs, it is recommended the tractor be equipped with a FOPS canopy to protect the operator from falling objects. DO NOT TRY TO WELD OR STRAIGHTEN THE ROPS. A .. ropes, or cables to the ROPS for pulling purposes; this will cause the tractor to tip backward. Always pull from the tractor drawbar. Be careful when driving through door openings or under low overhead objects. Make sure there is sufficient overhead clearance for the ROPS. WARNING: Never attach chains, A .. replaced, make certain that the proper hardware is used and the recommended torque values are applied to the attaching bolts. WARNING: If the ROPS is removed or A .. if the tractor is equipped with a ROPS. DO NOT use the seat belt if the ROPS is removed from the trador. WARNING: Always wear your seat belt Ford Built ROPS (iv)

UNIVERSAL SYMBOLS As a gUide to the operation of your tractor, various universal symbols have been utilised on the instruments and controls. The symbols are shown below with an indication of their meaning. ... .. T Air conditioner WI temperature control !;l\.. Engine speed (rev/min x CJ 100) % Hours recorded Remote cylinder (extend) ... ..... (retract) Remote cylinder '&Warning t& Engine coolant ~ temperature .i Fuel level (j) Engine stop control A Hazard warning ... ~ ~ Remote cylinder (float) ~ N Neutral + Fan 'Tortoise', slow or .... minimum setting 'Hare', fast or maximum setting Q Wipe/wash control ht. Transmission oil . pressure ~ Horn I Power take-off engaged .. ~ I -=- .. ffi.. Engine oil pressure :J Turn signal 1 Power take-off disengaged r ( ~ ) Transmission oil temperature Four wheel drive engaged ~ o Alternator charge C ) Parking brake tr' Four wheel drive III disengaged Heater temperature control ill' ~ D Work lamps ~ ~ f\ Lift arm/raise Differential lock m ff} asbestos Pressurised open slowly ~ ~ ), Lift arm/lower See Operator's Manual ~ "'" Continuously variable I :. 1 Corrosive I 07.. ~ Warning! Contains I substance OM 499 (v)

CONTENTS Page (i) (Ii) foreword safety precautions roll over protective structure (North America only) universal symbols (iv) (v) SECTION A CONTROLS, INSTRUMENTS AND OPERATION tractor controls engine starting/stopping procedure transmission four wheel drive operator's seat power take-off belt pulley hydraulic controls remote control valves three-point linkage track adjustment tractor weighting tyre inflation 2 4 7 9 11 13 15 16 20 25 35 48 52 B LUBRICATION AND MAINTENANCE lubrication and maintenance chart routine servicing general maintenance SECTION 2 3 24 c SPECIFICATIONS SECTION INDEX (vi)

-------------------SECTION A CONTROLS, INSTRUMENTS AND OPERATION The following pages in this section detail the location and function of the various instruments, switches and controls on your tractor. Before attempting to drive or operate the tractor, study this section carefully and ensure you are thoroughly familiar with all aspects of operation. If in doubt about any aspect of operation of the tractor, consult your Ford New Holland dealer. Particular attention should be paid to the recommendations for running-in to ensure that your tractor will give the long and dependable service for which it was designed.

---CONTROLS, INSTRUMENTS AND OPERATION--- INSTRUMENT PANEL The following text describes the function of the various warning lights and gauges on your tractor. See Figure 1 to locate these features on your tractor. Proofmeter Indicates engine revolutions per minute. Use the proofmeter in conjunction with the gearshift decal to determine the tractor ground speed. OM 279 The proofmeter also registers the hours and portions of hours the tractor has operated, based on an average engine speed of 2055 rev/min. Engine speeds below 2055 rev/min accumulate hours at a slower rate than clock hours. Engine speeds above 2055 rev/min accumulate hours at a faster rate than clock hours. The hours recorded should be used as a guide to determine hourly service intervals. (See Section B of this Manual). Instrument Panel 1. 1. 2. 3. 4. 5. 6. 7. Proofmeter Engine coolant temperature gauge Engine oil pressure warning light Work lamp indicator light Air cleaner restriction warning light Alternator warning light Fuel gauge Air Cleaner Restriction Warning Light (dry air cleaner only) Will illuminate when the air cleaner requires servicing. If the light illuminates while the engine is running, stop the engine and service the air cleaner, as described in section B. Engine Coolant Temperature Gauge Indicates the temperature of the engine coolant. If the needle enters the red sector while the engine is running, stop the engine and investigate the cause. NOTE: When the key-start switch is turned to 'ON' the light will illuminate to indicate that the lamp is functioning. The light will extinguish with the engine running and the air cleaner func- tioning correctly. The air cleaner warning light is connected into the oil pressure warning light circuit. In the event of low oil pressure both the air cleaner and oil pressure warning lights will be illuminated. NOTE: When the key-start switch is turned off the gauge needle assumes a random position. Engine Oil Pressure Warning Light Indicates low oil pressure and should extinguish immediately after the engine starts. IMPORTANT: If the light comes on whilst the engine is running, stop the engine and investigate the cause. Alternator Warning Light Indicates the battery is not being charged and should extinguish when the engine speed is increased above idle. Work Lamp Indicator Light (where fitted) Illuminates when the work lamp is switched on. The switch is on the rear of the lamp body. Fuel Gauge Indicates the level of fuel in the tank and is only operative with the key-start switch in the 'ON' position. NOTE: The work lamp is only operative with the main light switch in the 'ON' position. 2

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

-------------------SECTION A The fuel filler is situated on the left-hand side of the hood, immediately in front of the instrument panel. NOTE: When the key-start switch is turned off the gauge needle assumes a random position and may well indicate a fuel level in excess of the true level. HAND CONTROLS AND SWITCHES The follOwing text describes the function of the various switches and hand controls on your tractor. See Figure 2 to locate these features on your tractor. 2. Hand Controls and Switches 1. 2. 3. 4. 5. 6. 7. Hand throttle lever Hazard warning lights switch (except N. America) Horn push Tractor lights switch Engine stop control Key-start switch Turn signal switch (where fitted) Hand Throttle Lever Pull the lever rearwards to progressively increase engine speed. Tractor Lights Switch (except North America) The light switch is turned clockwise to operate the tractor lights. The switch has four positions: Hazard Warning Lights Switch (except N. America) Press the rear of the rocker switch to operate all the turn signals Simultaneously. The switch, which is internally illuminated, will flash in unison with the turn signals. Press the front of the switch to extinguish the hazard warning lights. Position (1) - Position (2) - Position (3) lights 'OFF' side and rear lights 'ON' side, rear and dipped beam headlights 'ON' side, rear and main beam headlights 'ON' Position (4) IMPORT ANT: In North America, hazard warning lights are used when driving on the public highway. The switch for the hazard warn- ing lights is on the left-hand lamp body. If tum signals are installed, they will operate as follows. When a tum signal is made, the lights on one side of the tractor will flash, indicating a tum, while the lights on the other side will bum continuously. For your protection, use the hazard warning lights when travelling on public roads, both day and night, unless prohibited by law. The hazard warning lights will only operate with the main lights switch on. NOTE: With the main beam headlights 'ON' a blue warning light on the tum signal switch body is illuminated. Tractor Lights Switch (North America only) The tractor lights switch, which is of the push-pull type, is located at position (4), Figure 2. The switch has three positions: Horn Push (except North America) Press to actuate the horn. The horn will only operate when the key-start switch is on.

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com