Fire-Resistant Joint Systems in Construction: 2021 IBC Overview

Understanding fire-resistance-rated joint systems is crucial in construction to ensure proper fire protection at assembly intersections. This presentation covers the requirements, testing methods, and examples of fire-resistant joint systems as per the 2021 IBC regulations, emphasizing the importance of matching ratings and ASTM E.1966 standards for testing.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Fire-Resistance-Rated Joint Systems: 2021 IBC Presented by: Michael Fiebig, RA, AIA, NCARB, LEED GA, CFPS, CEP

Fire-Resistance-Rated Joint Systems 2021 IBC In fire-resistance-rated construction, the joints where differing systems meet require fire protection, to the same degree that the assemblies require fire protection. These rules are found in Chapter 7 of the IBC (2021 edition used for this presentation), Section 715 2

Fire-Resistance-Rated Joint Systems 2021 IBC Fire-Resistance-Rated joints shall be installed at rated assembly intersections that include the following: -walls/partitions -floors -floor/ceiling assemblies -roofs -roof/ceiling assemblies. Ratings need to match, i.e. a 1-hour joint for 1-hour assemblies, etc. 3 Let s look at some of these defined terms.

Fire-Resistance-Rated Joint Systems 2021 IBC Fire-resistant joint systems must be tested! What does ASTM E 1966 require? 4

ASTM E 1966 Standard Test Method for Fire- Resistive Joint Systems 5

ASTM E 1966 Standard Test Method for Fire- Resistive Joint Systems Movement Cycling Test, and Fire Endurance Test 6

ASTM E 1966 Standard Test Method for Fire- Resistive Joint Systems Integrity Test, Load Application, and Hose Stream Test. Note: these are similar to the tests required in the ASTM E 119 test. 7

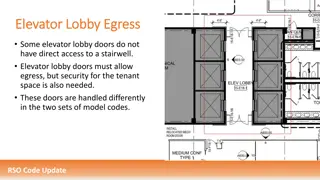

Example of fire-resistance-rated joint detail This example is a 2-hour rated fire barrier joining a concrete slab-on-ground floor and a 1- hour rated floor/ceiling assembly above. Note the top and bottom of the system require a fire-rated joint. 8

Example of fire-resistance-rated joint detail Bottom of wall joint test: UL BW-S-0002. Can anyone guess what the BW stands for in this tested assembly? 9

Example of fire-resistance-rated joint detail Top of wall joint test: UL HW-D-0262. Can anyone guess what the HW stands for in this tested assembly? 10

Additional UL Information From the UL Fire Resistance Directory (2016) This is important, because the wall/partition assemblies may have different head/sill specifications from the joints. 11

Additional UL Information Example: 1-hour rated partition UL U465 Per the partition assembly, fasteners for the floor/ceiling runners are to be spaced at 24 o.c. But what if dynamic movement is required? 12

Additional UL Information Example Head Joint: HW-D-0262 13

The Big Picture Important take aways: -Fire rated joints are separate systems, distinct from the rated assemblies they protect. -A tested joint system is required to be specified. -If dynamic movement is a relevant factor in the design (ex: walls that require a slip head track), the details of the joint system over-rule the details of the standard wall/partition. 14