Exploring Different Methods Of Molding ABS Plastic And Its Benefits

Whether itu2019s consumer electronics or automotive, for both, ABS Plastic is a very important component. ABS plastic is a very resilient substance that is renowned for its strength and superior impact resistance. This thermoplastic polymer is highly adaptable and commonly utilized. If you are looking for ABS Plastic Molds, then YuYao QiDi Plastic Mold is what you need.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Exploring Different Methods Of Molding ABS Plastic And Its Benefits

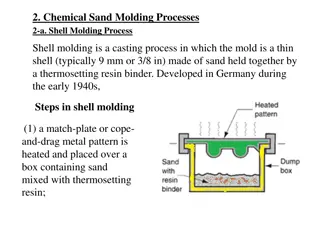

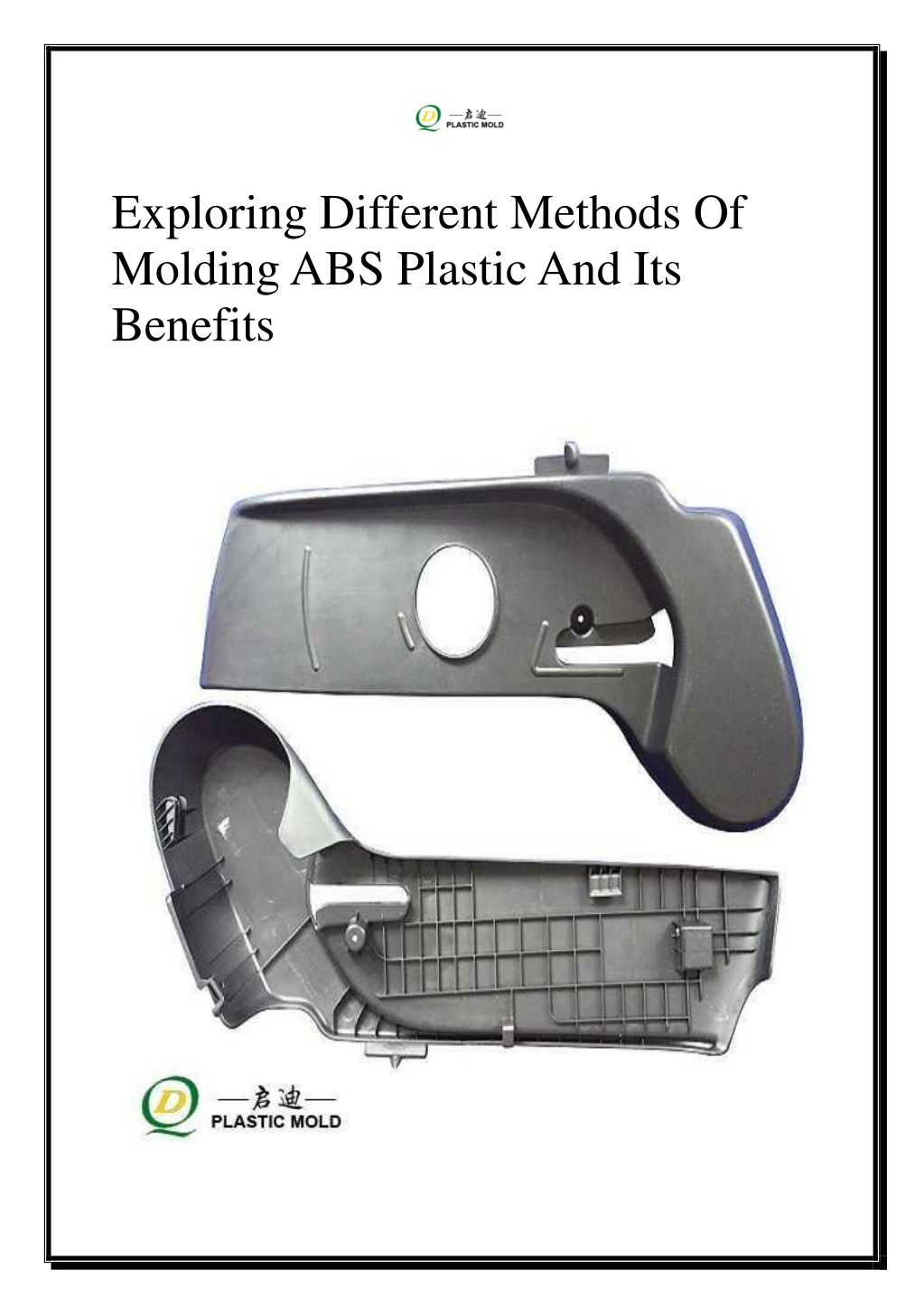

Whether its consumer electronics or automotive, for both, ABS Plastic is a very important component. ABS plastic is a very resilient substance that is renowned for its strength and superior impact resistance. This thermoplastic polymer is highly adaptable and commonly utilized. If you are looking for ABS Plastic Molds, then YuYao QiDi Plastic Mold is what you need. Let s take a closer look at ABS plastic in this post, as we also explore its molding procedure and discuss its advantages. Understanding ABS Plastic Acrylonitrile or ABS However, butadiene A thermoplastic polymer is styrene. Its three monomers are styrene, butadiene, and acrylonitrile. Because of its strong impact and heat resistance, machinability, and versatility, it finds usage in a multitude of applications. Understanding the Processes of Molding The first step in Molding ABS Plastic involves heating the thermoplastic resin to its melting temperature before injecting it under intense pressure into a mold hole. The finished object is expelled from the mold after it is opened when the plastic solidifies and takes on the shape of the mold as it cools. Injection Molding: During injection molding, the resin pellet of ABS is melted. After melting it, it is injected into a mold cavity under a very high pressure. The injection is done under high pressure. The finished product is released from the mold after the material has cooled and solidified. This method is used for more complex forms and is widely used. Compression Molding: In this method, a heated mold cavity is filled with a warmed resin or pellet, and the plastic is compressed into the required shape using pressure. Once it cools down and solidifies and the prepared part is removed by opening the mold. This process is commonly used to make parts with irregular shapes.

Extrusion Molding: Melted ABS plastic is pushed through a die during the extrusion molding process to produce continuous forms with a constant cross- section. After its solidification as it cools, it is cut to the desired lengths. Pipes and tubing are made with it. Exploring the benefits Let us now explore the advantages of ABS Plastic Molds: Surface finish: There is no need for a secondary finish operation because the prepared molds have an outstanding and smooth surface finish. Strength: It has very strength and is very strong because of which it is highly used in places with long term use in high volume production. Cost-effectiveness: Due to its low manufacture and maintenance costs, this option is affordable. Dimensional stability: It consistently delivers accurate and high-quality parts over time by maintaining high dimensional stability. Conclusion ABS plastic is a crucial component for automotive and consumer electronics due to its strength and superior impact resistance. It is an acrylonitrile, butadiene, and styrene thermoplastic polymer. The resin is heated to its melting point and then injected under pressure into a mold hole in the ABS plastic molding process. The methods of Molding include injection, compression, and extrusion. The most popular method, injection molding, is utilized for complex designs. Extrusion molding creates continuous forms with a consistent cross-section, whereas compression molding compresses the plastic into the desired shape. ABS plastic molds provide a smooth surface finish, great dimensional stability, durability, and cost-effectiveness because of their minimal maintenance and manufacturing expenses. Choose YuYao QiDi Plastic Mold for high quality service and excellent customer support.

Get in touch with YuYao QiDi Plastic Mold If you are looking for ABS Plastic Molding then YuYao QiDi Plastic Mold is the ideal solution for you as it offers services with high quality and excellent customer service. Contact us at: Website: YuYao QiDi Plastic Mold Email: info@cn-molds.com Whatsapp: 13605741887