Ethanol production

Ethanol, produced through fermentation by yeast in oxygen-free conditions, serves as a chemical feedstock, solvent, disinfectant, and fuel additive. The biochemistry involves sugar breakdown to pyruvic acid, then conversion to acetaldehyde and finally ethanol. Yeast growth in rich medium leads to ethanol production benefiting cell growth and energy needs. Key points include ATP production, ethanol recovery, and yield considerations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

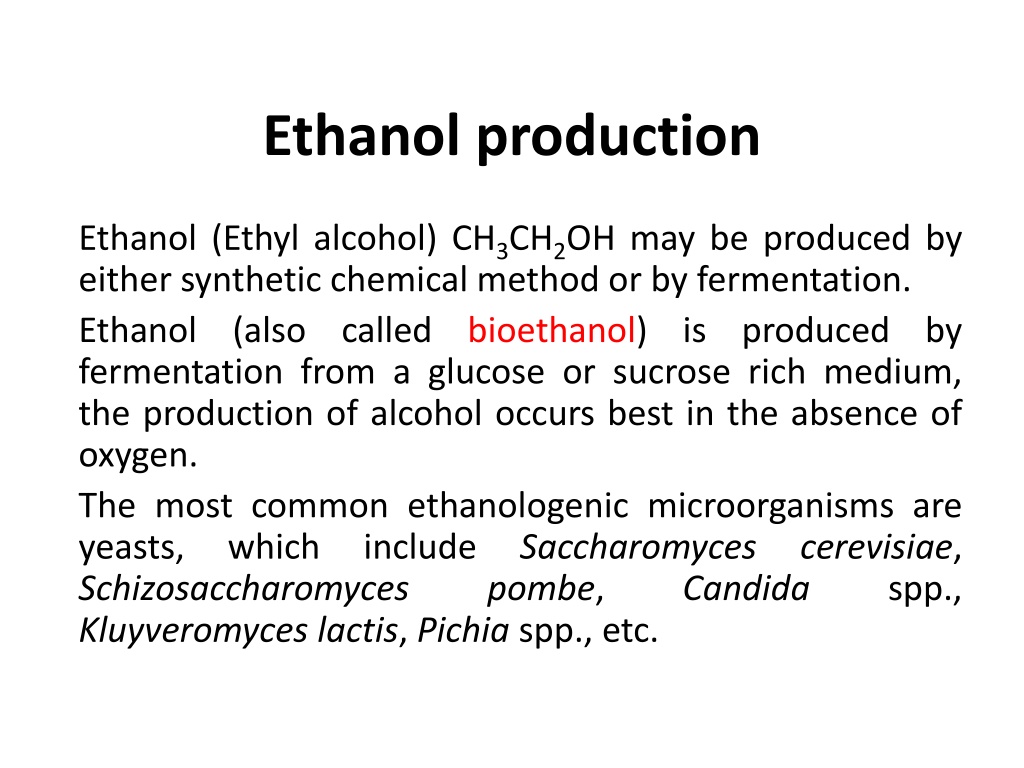

Ethanol production Ethanol (Ethyl alcohol) CH3CH2OH may be produced by either synthetic chemical method or by fermentation. Ethanol (also called bioethanol) fermentation from a glucose or sucrose rich medium, the production of alcohol occurs best in the absence of oxygen. The most common ethanologenic microorganisms are yeasts, which include Saccharomyces Schizosaccharomyces pombe, Kluyveromyces lactis, Pichia spp., etc. is produced by cerevisiae, Candida spp.,

Bacteria Clostridium mesenteroides are also involved in alcoholic fermentation. The yeast involved fermentation is Saccharomyces cerevisiae, directly ferment starch. such as Zymomonas and mobilis, sporogenes, Leuconostoc in these alcoholic strains which mostly of cannot

Uses of Ethanol (1) Use as a chemical feed stock: In the chemical industry, ethanol is an intermediate in many chemical processes. (2) Solvent use: Ethanol is widely used in industry as a solvent for dyes, oils, waxes, cosmetics etc. (3) General utility: Alcohol is used as a disinfectant in hospitals, for cleaning and lighting in the home, and in the laboratory second only to water as a solvent. (4) Fuel: Ethanol is mixed with petrol or gasoline up to 10% and known as gasohol.

Biochemistry of ethanol production The process starts with the breakdown of sugars into pyruvic acid via the Embden Meyerhof-Parnas (EMP) pathway, and then converted into acetaldehyde under anaerobic conditions through the enzyme pyruvate decarboxylase. Acetaldehyde further releases two molecules of carbon dioxide and forms ethanol by alcohol dehydrogenase.

Yeast grows rapidly in a glucose- or sucrose- rich medium, with a doubling time of about 60 minutes. High growth rates result in O2 depletion, and the neutral reaction products allow growth to be continued anaerobic mode.

Key points - Ethanol is the end point of the only metabolic pathway that yeast can use for ATP production. - ATP is produced at a low rate (2 ATP) and 2 moles of ethanol produced per mole of glucose, so that substrate is rapidly converted to product to provide the energy needs of cell growth. - Ethanol can escape into the medium rather than accumulating in the cell. This makes recovery of the product easier. Pure ethanol has to be recovered by distillation, which could represent the most expensive component of the production process. -Yield considerations. 1 ton of glucose can be converted into less than 0.5 ton of ethanol.

Ethanol Production process: - Preparation of the medium Mashing (Saccharification), this means the grain starch is hydrolyzed to sugars with microbial enzymes or with the enzymes of barley malt. In all the others no hydrolysis is necessary as sugars are present in the fermenting substrate as in grape sugar and cane sugar.

First, starch should be exposed to contact with water. Grinding makes small pieces, which can increase its surface area. Then, the increase in its surface area can enhance the contact between starch and water. At the grinding step, the outer shell of grain is almost completely removed, this step increases the surface area of each particle. These results make water penetrate through grain easily. However, there is still some undesirable area, which is hard to absorb water. To achieve effective enzymatic action, this micro-crystalline area should be removed.

micro-crystalline area removing: This is typically accomplished with two hot water processes. First, grain is treated with hot water, typically 85 C for between 20 to 60 minutes. Then, super-heated water, introduced with high pressure. With the first mixing with hot water, the starch absorbs water. Then, the structure of the micro-crystalline area becomes weak. Then, after introduction of super-heated water with high pressure, this area is completely broken. Without this water treatment, this area cannot be broken, which means the efficiency of the enzymatic action is lost. typically 110 C, is

In an ethanol industry, two enzymes are usually employed, endoenzyme alpha-amylase and exoenzyme glucoamylase. Alpha-amylase attacks the alpha-1,4 linkages of starch. Then, starch is converted into dextrin. After the first hydrolysis with alpha-amylase, glucoamylase works. Glucoamylase removes one glucose from dextrin. Thus, glucoamylase cuts linkage of dextrin from its end.

- Propagation of yeast inoculum In general the inoculum is made of selected alcohol-tolerant yeast Saccharomyces cerevisiae grown aerobically with agitation and in a molasses base. Yeast inoculum with Progressively larger volumes of culture may be developed before the desired volume is attained. strains usually up to 5% (v/v).

-Fermentation: Yeast is a facultative anaerobe. In the aerobic environment, it converts sugars into carbon dioxide and water, while in the anaerobic environment, it converts sugars into carbon dioxide and ethanol. Thus, for an ethanol industry, it is important to exclude significant oxygen from its system. Alcohol-resistant yeasts, strains of Saccharomyces cerevisiae are used, and nutrients such as nitrogen and phosphate lacking in the broth are added. When the nitrogen content of the medium is insufficient nitrogen is added usually in the form of an ammonium salt.

In all alcohol fermentations the heat released must be reduced by cooling and temperatures are generally not permitted to exceed 35-37 C. The pH is usually in the range 4.5-5.0, when the buffering capacity of the medium is high, higher pH values tend to lead to higher glycerol formation. When the buffering capacity is lower, the pH is falls to about 3.5., the contaminations can have serious effects on the process( sugars are used up leading to reduced yields).

-Distillation Distillation is one of the steps of the purifications. Distillation is the method to separate two liquid utilizing their different boiling points. After fermentation contains alcohol as well as low boiling point volatile compounds such as acetaldehydes, esters and the higher boiling, fuel oils. the fermented liquor

The alcohol is obtained by several operations. First, steam is passed through the liquor. The result is a dilute alcohol solution which still contains part of the compounds. Secondly, the dilute alcohol solution is passed into the center of a multi-plate aldehyde column in which the following fractions are separated: esters and aldehydes, fuel oil, water, and an ethanol solution containing about 25% ethanol. Thirdly, the dilute alcohol solution is passed into a rectifying column distils off at 95.6% alcohol concentration. undesirable volatile

The maximum alcohol concentration of 96.58% is obtained by azeotropic distillation. The principle of this method is to add an organic solvent which will form membered) azeotrope with most of the water, but with only a small proportion of the alcohol. Benzene, carbon tetrachloride, chloroform and cyclohezane may be used, but in practice, benzene is used. In practice,four columns are usually used. The first and second columns remove aldehydes and fuel oils, respectively, while the last two concentration of the alcohol. a ternary (three towers are for the

Some Developments in Alcohol Production (1) Developments of new strains of yeast of Saccharomyces uvarum able to ferment sugar rapidly, to tolerate concentrations, flocculate rapidly. (2) The use of continuous fermentation with recycle using the rapidly flocculating yeasts. (3) Continuous vacuum fermentation in which alcohol is continuously evaporated under low pressure from the fermentation broth. high alcohol

(4) negative bacterium which is found in some tropical alcoholic beverages. The advantages claimed Zymomonas are the following: (a) Higher specific rates of glucose uptake and ethanol production than reported for yeasts. (b) Higher ethanol yields and lower biomass than with yeasts. (c) Ethanol tolerance is at least as high or even higher [up to 16% (v/v)] in some strains of the bacterium than with yeast. The use of Zymomonas mobilis, a Gram- for the use of

(d) Zymomonas also tolerates high glucose concentration and many cultures grow in sugar solutions of up to 40% (w/v) glucose which should lead to high ethanol production. (e) Zymomonas grows anaerobically and, unlike yeasts, does not require the controlled addition of oxygen for viability at the high cell concentrations used in cell recycle. (f) The many techniques engineering already worked out in bacteria can be easily applied to Zymomonas for greater productivity. for genetic