Different Methods of Textile Scouring Explained

Wool scouring and solvent scouring are two essential processes in textile production. Wool scouring involves removing wool grease before spinning yarn, while solvent scouring uses solvents to clean fabrics like polyester and nylon. Solvent scouring offers benefits like simultaneous desizing and bleaching, minimal residual matter, and reduced water pollution. It is particularly effective for fabrics that do not have to be desized.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Type of Scouring Faiza Anwar

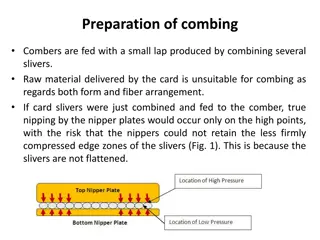

Wool scouring Wool scouring differs from cotton in two essential respects; raw wool contains a large amount of wool grease in comparison with 0.5 percent oils and waxes in cotton and wool is rapidly degraded by alkali. Sodium hydroxide is never used, instead, sodium or ammonium carbonate are preferred. Raw wool must be scoured before it can be spun into yarn.

Solvent scouring Solvent is a liquid, solid, or gas that dissolves another solid, liquid, or gaseous solute, resulting in a solution Particularly for fabrics which do not have to desize, polyester, nylon, acetate, acrylic, and woolen goods Usually chlorinated hydrocarbons, e.g. tetrachloroethylene, trichloroethylene and 1,1,1- trichloroethane.

Solvent scouring This process not only permits scouring, but also simultaneous scouring and desizing or even partial bleaching in one step Basically solvent scouring is a refinement of dry-cleaning and is carried out either batchwise or continuously

Solvent Scouring Certain organic solvents will readily dissolve oils fats and waxes and these solvents can be used to purify textiles. There are commercial processes where textiles are cleaned with organic solvents. Fabrics processed this way are said to be "Dry Cleaned". For fabrics that do not have to be desized, solvent scouring is an effective way of removing fiber producer finishes, and knitting oils. Knitted fabrics made from nylon, polyester, acetate and acrylics, are particularly amenable to this method of preparation.

Solvent Scouring Wool grease is effectively removed by solvent scouring. Solvent Extractions are particularly useful in the laboratory for determining the amount of processing oils added to man- made fibers and the residual amounts of oils and waxes left by aqueous scouring. Properly controlled, fabrics can be produced with very little residual matter. The continuous, solvent scouring range is enclosed so the vapors are contained and not allowed to escape into the atmosphere.

Solvent scouring Solvent processing has been established due to: reduced water pollution reduced energy cost and consumption apart from effective removal of impurities Solvent preparation gives excellent results in terms of uniformity, reproducibility and high absorbancy

Solvent scouring Solvent recovery requires special equipment Solvent do not aid to remove motes, metal ions , starch, etc The need for systems to recover the solvent from fabrics after processing.

Some Important Solvents are: Solvents Boiling Point Surface Tensions Dynes/cm Heat of Vaporization Calories/gram Trichloroethylene 87 C 28.7 57 Perchloroethylene 121 C 32.3 50 Methylene Chloride 39.8 C 27.2 78.7 Water 100 C 72 545

Advatangesof Solvents Recovery units are installed on the range to insure that. none of the solvent is allowed to vent to the environment. Organic solvents have a number of advantages that make them particularly useful for wax removal. Solvents dissolve almost all oils and waxes. They have low liquid surface tensions and quickly and easily wet out and penetrate fabrics with waxes. They are much easier to evaporate than water, requiring less time and energy.

Side effects and Limitations of Solvents On the negative side hydrocarbon solvents are flammable and present explosion hazards. Most chlorinated solvents are proven or suspect carcinogens and some are known to contribute to atmospheric ozone depletion. Chlorinated hydrocarbons thermally decompose to form phosgene and hydrochloric acids. These decomposition by-products are corrosive to metals and also damage cellulosic fibers. Solvents are expensive so they must be recovered and purified by distillation requiring special equipment. The distillation residue becomes a solid waste disposal problem. Solvents do not aid in the removal of other impurities like metal ions,etc.

Enzyme scouring Enzymes are biochemical which have a specific action on only one type of the compound which bring about a chemical change in it. They are contained with all living system and carry many functions. Enzymes are used to digest the impurities this process is also known as bio- scouring Lipases, Cutinases, Pectinases and Proteases.

Tests for Effective Scouring AATCC Test Method Number 79 Properly scoured fabric should wet out faster and be more water absorbent. AATCC Test Method No. 79 is used to measure fabric wetting. A drop of water is placed on the fabric and the time it takes for the drop to penetrate the fabric is recorded. The faster the wetting time, the more absorbent the fabric.

Tests for Effective Scouring Absorbency: Drop Test Less than 5 sec Other tests Wicking Height Sinking Test Weight loss is also checked Residual Wax Content Wax is dissolved solvent Solvent is distilled off The sample is reweighed Removal of Motes Observed visually and given a rating of 1-5

References Eurotex, An introduction to textiles. Vol. IV, Textile Wet Processing Chemical technology in the pretreatment processes of Textiles, By: S.R Karmakar Chemistry and Technology of Fabric preparation and Finishing, by Charles Tomasino.