Comprehensive EMI Design Suite for Effective EMI Management

The EMI Design Suite aims to address EMI issues upfront in product development, offering insight to system engineers, guiding hardware selection, assisting in EMI filter design, and streamlining EMI testing and debugging. By focusing on EMI requirements from the start, the suite enhances overall product quality and compliance.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

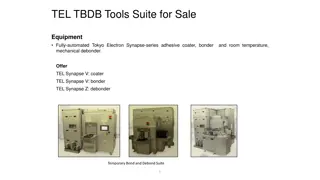

EMI Analysis and EMI Filter Design in PSIM Powersim Inc. February 2021

Typical Product Development Steps System engineering per customer/marketing specifications - Simulate and prototype to evaluate system power performance - Provide detailed engineering/testing specifications Design engineering per engineering specifications - HW components selection, board and system layout - SW development Testing engineering per testing specifications - Functional - Debug HW/SW - Thermal - Reliability - EMI EMI pre-compliance testing per EMI standards - Set up - Debug

Problem Statements There are no considerations and detailed engineering specifications related to EMI requirements (except EMI standards) from system engineering. When design engineers design the product, they tend to optimize the design for space, volume, power, cost and performance, but not EMI compliance. The EMI testing is always the very last step by testing engineers - Functional - Debug HW/SW - Thermal - Reliability - EMI EMI pre-compliance set-up and debugging tasks are very confusing and time consuming

Objectives of the EMI Design Suite The main goal: To address EMI issues upfront, not leave it as afterthought. To help system engineers gain a better insight of the subsystem operations from EMI perspective and derive detailed hardware/mechanical layout specifications. To help hardware engineers carry out hardware component selection and EMI filter design to meet the EMI requirements before the actual circuit boards/system layout starts. To assist EMI debugging and find solutions after the hardware is built. To help EMI testing engineers quickly integrate and perform EMI pre-compliance testing of the system.

Causes of the EMI Noises di/dt coupled with parasitic inductances and ESR of input capacitors dv/dt coupled with parasitic capacitances => DM => CM

Causes of the EMI Noises Frequency Domain Spectrum Switching Waveforms Overlay EMI noise spectrum on top of CISPR 22 Standard CM CISPR 32/22 (Class B) 100 80 60 40 20 0 -20 500k 1M 5M 10M 50M 100M Frequency (Hz)

Mitigate EMI Noises Possible EMI solutions without changing topology and modulation method: Set fsw value lower than of EMI standard lower frequency limit Minimize parasitic inductances/capacitances with proper layout and component selection Reduce dv/dt => Increase power loss Use slower device Increase gate resistance Add snubber Optimal number of filter stages

Accurate EMI Analysis and EMI Filter Design in Simulation Accurately predict switching waveforms in time domain and the frequency domain spectrums of these switching waveforms Measure EMI components (LISN, Signal Analyzer, CM/DM noise separator) Overlay EMI standards over EMI noise spectrums Accurately predict the parasitic inductances and capacitances in the circuit

EMI Design Suite Template A general design template is provided. Users can add their own circuits to this template. The following library blocks are provided: LISN EMI Filter Signal Analyzer (for CM and DM) Parasitic Capacitance Block Design Input Panel

EMI Design Suite Examples 5 design examples are provided. Buck (CISPR-22 Class-B) Boost (MIL-461 440V) PFC (FCC Class-B) PSFB DC-DC (CISPR-25 Level-4) PMSM Drive (CISPR-25 Level-3)

EMI Filter Design of PSFB Converter (CISPR25-Level 4) Without EMI filter With EMI filter CM CISPR 25 (Class 4) CM CISPR 25 (Class 4) 120 60 100 40 80 20 60 0 40 -20 20 -40 0 -60 DM CISPR 25 (Class 4) DM CISPR 25 (Class 4) Frequency (Hz) Frequency (Hz) 120 80 100 60 80 40 60 40 20 20 0 0 -20 -20 -40 -40 EMI CISPR 25 (Class 4) EMI CISPR 25 (Class 4) Frequency (Hz) Frequency (Hz) 80 120 60 100 40 80 20 60 0 40 -20 20 0 -40 500k 1M 5M 10M 50M 100M 500k 1M 5M 10M 50M 100M Frequency (Hz) Frequency (Hz)

Running LTspice Simulation in EMI Design Suite Environment Use Spice models provided by manufacturers. Bridge the gap between complex system simulation using the PSIM engine and detailed component investigation using the LTspice engine. Leverage built-in EMI components from the EMI Design Suite: Automatic EMI filter design LISN Signal Analyzer (with CM/DM noise separation) Parasitic Capacitance Block Leverage rich set of post-processing functions in PSIM: FFT Overlay of various EMI standards Automatic unit conversions from Volts, Amps to dBuV

EMI Filter Design of Buck Converter (CISPR22 Class-B) (using LTspice engine) CM CISPR 32/22 (Class B) 100 80 60 40 20 0 -20 1M 10M 100M 1G Frequency (Hz)

Benefits of the EMI Design Suite In the early design stage (pre-hardware build-up): To provide a qualitative and step-by-step guidance in EMI analysis and filter design To study different what if scenarios, and study the effect of switching transient To provide guidance for board and system layout, or study the effect of the existing layout with consideration of various common-mode and parasitic components To provide a common platform for system/HW/testing engineers to communicate and work through the EMI design/testing related issues

Benefits of the EMI Design Suite (contd) In the late design stage (post-hardware build-up and design iterations): To assist EMI debugging and finding solutions after the hardware is built To load customer EMI measurement data, and use this data design the EMI filter using EMI Design Suite To help reduce the time for EMI filter design, debugging, and certification process significantly