Caterpillar Cat D6R TRACK-TYPE TRACTOR (Prefix 4HN) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Service Repair Manual Models D6R TRACK-TYPE TRACTOR

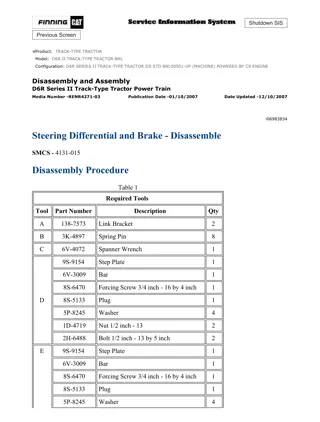

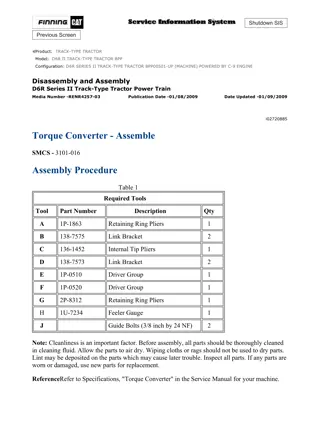

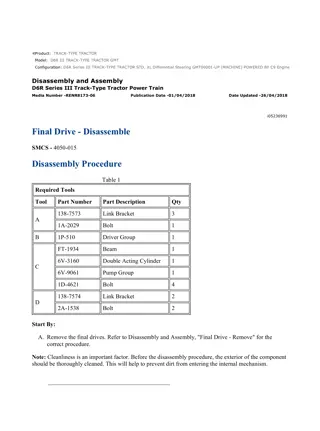

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 1/15 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D6R TRACK-TYPE TRACTOR 4HN Configuration: D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Engine Disassembly and Assembly D6R TRACK-TYPE TRACTOR POWER TRAIN Media Number -SENR8357-02 Publication Date -01/05/2005 Date Updated -03/06/2014 SENR83570004 Track SMCS - 4170-015; 4170-016; 4170-076; 4170-077; 4170-010 Separate Track The machine must be on a level hard surface before a separation of the track is made. Any time a separation of both tracks is made the machine must have blocks correctly in position so the machine will not move. Typical 1. Remove track adjuster cover (1) and the O-ring seal from the roller frame. The adjuster cylinder for the track is under high hydraulic pressure. Do not visually inspect the relief valve to see if grease is released when it is https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 2/15 open. Look to see that the track has loosened. Use this warning any time the tracks are loosened or tightened. 2. Loosen the track as follows: a. Turn the relief valve (2) one turn counterclockwise to permit grease to be released from the track adjuster. If the track does not loosen go to Step b. b. Turn fill valve (3) one turn counterclockwise to permit grease to be released from the track adjuster. If the track still does not loosen, start the machine and move it forward and backward. If grease is still not released go to Step c. c. Install a piece of round bar stock between the bushing and sprocket inside the links. Move the machine to the rear so the track will be pushed up by the round bar stock. This will put tension on the track and move the track adjuster in. 3. Move the track until the master link is just above the centerline of rear idler (4). Put wood blocks under the grouser bar just below the master link. Move the track to the rear until it has rigid contact with the wooden blocks. 4. The weight of the master shoe is from 19.5 kg to 37.5 kg (43 lbs to 82.5 lbs), depending on which track the vehicle is equipped. Remove four bolts (5) and master shoe (6). 5. Separate master link (7). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 3/15 Keep away from the front of the machine when the track is pushed off of the final drive. A minimum distance of 6.1 m (20 ft) is needed in front of the track to permit the track to move out on to the floor. 6. Fasten a chain to the end of the track and to a wheel loader or similar machine. Turn the final drive in a forward direction and let track (8) fall forward, as the wheel loader or similar machine is moved forward. 7. The weight of the track is from 1676 to 2602 kg (3687 to 5724 lbs) depending on which track the machine has on it. Lift the side of the machine and remove the track if necessary. Connect Track 1. Put the track under the machine. Lower the side of the machine on to track (8). 2. Fasten one end of the chain to track (8) and the other end to a wheel loader or a similar machine. NOTICE To avoid damage to the track or to the machine, the track must be pulled in a straight line. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 4/15 3. Pull the track until the track bushings engage with the sprocket segments on the final drive. 4. Start the machine and turn the final drive in a reverse direction to pull the track together. 5. Lift the end of the track and put wooden blocks (9) under the grouser as shown. NOTE: Make sure the serrations on the master link are free of loose or thick rust, paint, and lubricants. 6. Align the lower end of master link (7) with the upper end of the master link. Make sure the teeth of both ends of the master link are engaged. 7. Put track shoe (6) in position on the master link. Put 2P2506 Thread Lubricant on the threads, body and washer face of the master link bolts. Install bolts (5) that hold the master link together. Tighten the bolts to a torque of 400 70 N m (300 50 lb ft). Tighten the bolts an additional 1/3 of a turn. For inspection purposes, after assembly, the final torque must be a minimum of 680 N m (500 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 5/15 8. Tighten relief valve (2) and fill valve (3) in the track adjuster to a torque of 35 7 N m (25 5 lb ft). NOTICE Measure the track (sag), distance from a straight line when the machine is in its working condition. If dirt and debris are present in its working condition, then measure the (sag) when normal dirt and debris are present in the track and its components. 9. Adjust the track as follows: a. Move the machine forward for a distance that is two times the length of the machine. Let it come to a stop without the use of the brakes. b. Put a tight line between the grouser tips at the sprocket and front idler. c. Measure distance (X) from the line to the lowest point of (sag) of the grouser tips. Put 5P960 Multipurpose Type Grease in the track adjuster and make an adjustment to the track until distance (X) is 115 10 mm (4.53 .40 in). This is the sag (curve) in the track between the sprocket and the front idler. d. Do not tighten the track more if distance (Y) is 150 mm (5.9 in) or more. The track will have to be removed and reconditioned. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 6/15 10. Install the track adjuster cover (1) and O-ring seal onto the roller frame. Track Adjustment-Adjust Grease is under high pressure. Grease coming out of the relief valve under pressure can penetrate the body causing injury or death. Do not watch the relief valve to see if grease is escaping. Watch the track or track adjustment cylinder to see if the track is being loosened. Loosen the relief valve only one turn. 1. Move the machine forward. Allow the machine to stop without the use of service brakes. Adjust the tracks while you are in the machine's typical operating conditions. If packing conditions prevail on the workplace, the tracks should be adjusted with packing material. NOTICE Do not attempt to tighten track when dimension (1) is 105 mm (4.13 in) or more. Contact your Caterpillar dealer for track service instructions. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 7/15 2. The sag in the track is measured between the sprocket and the front idler (2). The correct adjustment of dimension (2) is 100 10 mm (3.9 .40 in). 3. If the machine is equipped with a carrier roller, the correct adjustment of dimension (3) and dimension (4) is 130 10 mm (5.12 .38 in). Disassemble Track https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 8/15 1. Put the track pin, to be removed, in position behind the front idler as shown. 2. Put blocks (2) in position under the front of the track. 3. Put blocks (3) in position under the track to keep the track away from the track roller frame when the pressure is released in the track adjuster. 4. Release the pressure in the track adjuster. See topic, Separate Track. 5. Put Tool (A) in position as shown. Use Tool (A) to keep the track in position when the track pins are removed. 6. Remove the bolts, and use two persons to remove three track shoes (1) over the track pins to be removed. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 9/15 7. Fasten a hoist to Tooling (B). Put Tooling (B) in position against the track pin. 8. Push the track pin out of the track with Tool (B), and install Tool (C) to hold the track together until the other track pin is removed. 9. Put Tooling (B) in position against track pin (4). Push track pin (4) out of the track, and install Tool (C). Remove Tooling (B) from the track. 10. Put Tooling (D) in position between links (6) and (7). Use Tooling (D) to spread the links apart far enough to move link (5) away from links (6) and (7). 11. Remove Tooling (C) from links (5), (6) and (7) NOTICE Use care when moving the links apart so the face of the seals are not damaged. 12. Fasten a hoist to link (5). Move the link away from links (6) and (7). 13. Put a block under link (5) to keep it away from links (6) and (7) 14. Put Tooling (D) in position between links (9) and (10). Use Tooling (D) to spread the links apart far enough to remove link assembly (8). 15. Fasten a hoist to link assembly (8). 16. Remove Tool (C) from links (9) and (10) and link assembly (8), and remove the link assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 E... 10/15 17. Remove seal assemblies (11) from the track links. 18. Put the track links and track bushing in position in Tooling (E) as shown. Push the track bushing from track link (6). 19. Put track link (7) and the track bushing in position in Tooling (E). Remove the track bushing from track link (7). 20. Use a punch and hammer, and remove plug (12) from stopper (13) in the track pins. 21. Remove stoppers (13) from the track pins. Assemble Track https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 E... 11/15 NOTE: Check all parts of the track assembly for wear or damage. Make replacements if necessary. Make sure the parts are clean and dry before assembly. 1. Put 1P3482 Adapter (2) [part of Tooling (A)] in frame (1) of the press arrangement [part of Tooling (A)] with the counterbore toward the ram as shown. NOTICE Use a maximum force of 760 kN (170 000 lb) when the track is assembled. Excessive press force can cause damage to the thrust rings. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 E... 12/15 2. Put SAE 90 gear oil on each end of track bushing (4) for a minimum length of 5 mm (.197 in). 3. Use Tooling (A), and install track bushing (4) into track link (3). Push the track bushing in until it makes contact with Tooling (A). The track bushing must extend 1.76 0.13 mm (.069 .005 in) above the surface of the track link. 4. Put track link (5), track bushing (4) and track link (3) in position in Tooling (B). Install pin (6) [part of Tooling (B)] for alignment purposes. Use Tooling (B), and install the track link on the track bushing until the track makes contact with Tooling (B). The track bushing must extend 1.76 0.13 mm (.069 .005 in) above the surface of the track link. NOTICE The seal assemblies must be completely sealed in the track link counterbores. The load rings of the seal assemblies must make a minimum amount of contact with oil. Oil causes the load ring to expand. This is not desired until after assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 E... 13/15 NOTE: Make sure there is contact at area (X) between the seal and load ring. 5. Use Tool (C) and install the seal assemblies (the seals and load rings) in the track links as shown in illustration A82927P1. 6. Put oil on stoppers (7), and install them in track pins (8). The stopper must be installed to a depth of 8 4 mm (.315 .157 in) below the surface of the track pins. 7. Put Tooling (D) in position between the track links. Use Tooling (D) to spread the links apart far enough to install link assembly (9) 8. Fasten a hoist to link assembly (9). Put the link assembly in position, and install Tooling (E) to hold it in place. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 E... 14/15 9. Put Tooling (D) in position between links in link assembly (9). Use Tooling (D) to spread the links apart far enough to install link assembly (10). 10. Fasten a hoist to link assembly (10). Put the link assembly in position on the link assembly (9). 11. Align the pin hole in link assembly (10) with the hole in link assembly (9), and install tool (E). 12. Fasten a hoist to Tooling (F). Put Tooling (F) and track pin (12) in position on the track links. NOTE: The pin must be installed with the hole end on the same side of the track assembly for the entire length of the track assembly. The oil cross hole in the pin must be within 20 of the vertical centerline of the pin bore and closest to the rail of the link. The pins have a mark on the end for crosshole location. Also, the pin must be installed with a minimum amount of force to get a maximum amount of end play 0.13 mm (.005 in) between the bushing and the thrust ring. 13. Install track pin (12) with Tooling (F) until the pin extends 3.22 mm (.127 in) beyond the link assembly on both sides. 14. Put track pin (11) and Tooling (F) in position on the track links. Install track pin (11) until it extends a maximum of 3.22 mm (.127 in) beyond the link assembly on both sides. 15. Use two persons, and put three track shoes (13) in position. Put 2P2506 Thread Lubricant on the threads, body and washer's face of the master link bolts. Install the track shoe bolts and nuts. Make sure the radius corner of the nuts are away from the links. Tighten the bolts to a torque of 400 70 N m (300 50 lb ft). Tighten the bolts 1/3 turn more. For inspection purposes, after assembly, the final torque must be a minimum of 680 N m (500 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 E... 15/15 16. Remove Tooling (G). 17. Fill the track pins with a minimum of 50.0 ml (1.7 oz) of SAE 90 gear oil. 18. Put oil on the plug, and install the plug in the stopper in the end of the track pin with Tool (H). Install the plug until it is even with the end of the stopper. 19. Adjust the track. See topic, separate And Connect Track in this module for the adjustment procedure. Copyright 1993 - 2020 Caterpillar Inc. Mon Apr 27 12:08:59 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 1/4 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D6R TRACK-TYPE TRACTOR 4HN Configuration: D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Engine Disassembly and Assembly D6R TRACK-TYPE TRACTOR POWER TRAIN Media Number -SENR8357-02 Publication Date -01/05/2005 Date Updated -03/06/2014 SENR83570005 Field Repair for Dry Joints in Rotating Bushing Track (RBT) SMCS - 4170 D7R Tractors Equipped with Rotating Bushing Track (RBT) Introduction NOTE: Seals are not shown. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 2/4 Components of rotating bushing track. (1) Bushing. (2) Inner seals and thrust rings. (3) Outer seals and thrust rings. (4) Pin groove. (5) Inserts. The bushings are located between the track links and are not pressed into the bushing bores. Inner seal and thrust ring (2) and insert (5) are located in each bushing bore. Insert (5) is factory installed and is not serviceable. A portion of the pin boss is extruded (pressed) down and into groove (4) in the end of the pin. The process of pressing the link material helps to retain the pin in the joints. The extrusion process (method) of retaining the pins is a factory assembled procedure. Tools are not yet available to do this type of pin retention in a field repair situation. A welding procedure is available, however, for use in retaining the pins in a field repair of rotating bushing track. The procedure given in this Special Instruction can be used to replace a damaged joint in rotating bushing track (RBT). When this procedure is followed precisely, the joints can be welded without causing damage to the non-metallic parts, including the seals, that are inside the joint. Do not perform any procedure, outlined in this publication, or order any parts until you read and understand the information contained within. Reference: For more detail refer to, Special Instruction SEHS8957, "Repair Procedure for Non- Restrained Seals and Lubricated Track". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 3/4 Repair Procedure Disassembly Make reference to Special Instruction, SEHS8957, for a complete list of tools, field repair procedure, and any additional information that may be needed. Standard tools for the D6H Tractor can be used in the procedure. 1. Inspect the track and locate the dry joint. 2. Follow the procedure given under the topic entitled "Link Section Removal of Damaged Joint" in the reference Special Instruction. 3. Pressing out the pin, sometimes cuts off extruded material from the pin bores. Inspect for loose extruded material in the seal cavities after the pins have been removed. Assembly 1. Use the following Weld Procedure as a replacement for the procedure given under the topic entitled "Link Section Buildup with 8T7780 Track repair Group" in the reference Special Instruction. 2. Equalize the pin projection in each joint to be repaired. Set each joint to zero end play. Weld Procedure NOTE: Equalizing the projection at each end of the pin permits an approximate 6-10 mm (1/4-3/8 in) fillet at each end of the pin. Pin projection (solid end of pin shown). 1. Use an E6011 Weld Electrode to make a weld bead for approximately 120 degree (13 the distance) around the circumference of the pin end as shown. 2. Immediately after the 120 degree weld bead is completed, put a wet paper towel (1U9579 Paper Towel) directly om the weld bead. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 4/4 Cover the entire end of the pin with the wet paper towel. Leave the towel in place 3-5 minutes while welding the ends of the other pins. Wet paper towel on the end of pin. 3. The ends of the pins must be cool to the touch before continuing the weld process. Repeat Steps 1 and 2 until the bead covers the entire circumference of the pin ends. Completed weld (end of pin shown). Completed weld (hole end of pin shown). Note the undamaged stopper and plug in the end of the pin. 4. After all welding has been completed, refer to the topic entitled "Link Section Installation" in the reference Special Instruction for the track assembly and joint lubrication information, and for track installation information. 5. For track adjustment, refer to the topic entitled "Recommended Track Adjustment procedure" in the reference Special Instruction. Copyright 1993 - 2020 Caterpillar Inc. Mon Apr 27 12:09:48 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 1/1 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D6R TRACK-TYPE TRACTOR 4HN Configuration: D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Engine Disassembly and Assembly D6R TRACK-TYPE TRACTOR POWER TRAIN Media Number -SENR8357-02 Publication Date -01/05/2005 Date Updated -03/06/2014 SENR83570006 Sprocket Segments SMCS - 4155-010 Remove & Install Sprocket Segments 1. Move the machine forward or backward until segment (2) to be removed, is in position as shown. 2. Remove five bolts and nuts (1) and remove segment (2). NOTE: The following steps are for installation of the sprocket segments. 3. Make sure the mating surfaces of the sprocket segment and the final drive are clean and free of rust and scale. NOTE: Install the segment so the head of the bolts are against the segment, and so the washers and nuts (1) are against the final drive. 4. Put SAE 30 oil on the threads of the segment bolts. Put the segment in position on the final drive and install bolts, washers, and nuts (1). Tighten nuts (1) to a torque of 175 40 N m (130 30 lb ft). Tighten the nuts 1/3 of a turn more. Copyright 1993 - 2020 Caterpillar Inc. Mon Apr 27 12:10:37 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 1/6 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D6R TRACK-TYPE TRACTOR 4HN Configuration: D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Engine Disassembly and Assembly D6R TRACK-TYPE TRACTOR POWER TRAIN Media Number -SENR8357-02 Publication Date -01/05/2005 Date Updated -03/06/2014 SENR83570007 Front Track Roller Frames SMCS - 4151-012; 4151-011 Remove Front Track Roller Frames Start By: a. Separate track NOTE: The track roller frame does not have an oil drain plug. To avoid an oil spill when the front track roller frame is removed from the rear track roller frame, use a vacuum pump in the opening, near the track adjuster valve, to remove the oil. If a vacuum pump is not available, the oil will drain when the front track roller frame is removed from the rear track roller frame. 1. Remove six bolts (1) and guide assembly (2) from each side of the rear track roller frame. Remove the O-ring seal from each end of the guide assemblies. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 2/6 2. Remove one bolt from each side of the front idlers and install Tooling (A). 3. Attach one end of Tooling (B) to Tooling (A). Attach the other end of the Tooling (B) to a stationary object. Use Tooling (B) to pull the front track roller frame out of the rear track roller frame until the bearing is free from the seal. Remove Tooling (B). 4. The weight of the front track roller frame is 546 kg (1200 lb). Put a nylon strap (3) around the front track roller frame and attach a hoist. Adjust the strap so the front track roller frame will be level and remove it from the rear track roller frame. 5. Put the front track roller frame on blocks as shown. Use a torch and remove bearing (4) from the front track roller frame if necessary. 6. Remove seal assembly (5), ring (6), and bearing (7) from the rear track roller frame. Install Front Track Roller Frame https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 3/6 1. If it is necessary to replace bearing (1), remove the track adjuster from the front track roller frame. See Remove and Install Track Adjuster in this module for the proper procedure. 2. Put dry ice in the front track roller frame tube to lower the temperature of the tube. Heat bearing (1) to a maximum temperature of 175 C (350 F). Install bearing (1) onto the front track roller frame. Install the bearing so that it is a maximum of 1 mm (.039 in) away from the plate at the front of the roller frame. 3. Install the track adjuster into the front track roller frame. See Remove And Install Track Adjuster in this module for the proper procedure. 4. Install bearing (2) and ring (3) into the rear track roller frame. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 4/6 NOTICE Make sure Tooling (A) and Tooling (B) put pressure on the outer ring of seal assembly (4) when they are used to install the seal assembly into the rear track roller frame. 5. Put 7M7456 Bearing Mount on the outer diameter of seal assembly (4). Put seal assembly (4) and Tooling (A) in position in the rear track roller frame as shown. 6. Tighten two nuts [part of Tooling (A)] evenly and pull seal assembly (4) in until it is even with the front surface of the rear track roller frame. 7. Use Tool (B) and install seal assembly (4) to the bottom of the counterbore in the rear track roller frame. 8. Put seal guard [Tooling (C)] in position on the inner diameter of seal assembly (4). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 5/6 NOTICE Use care to avoid causing damage to seal assembly (4) and bearing (2) when the front track roller frame is installed. 9. Put SAE 30 oil on the outer diameter of the front track roller frame bearing (1). 10. Put a nylon strap around the front track roller frame. Adjust the nylon strap so the front track roller frame is level. Put the front track roller frame into the rear track roller frame and allow enough room to remove Tooling (C). Remove Tooling (C). 11. Install Tooling (D) onto the rear track roller frame. Install Tooling (E) onto the front track roller frame. Attach the ratchet pullers [part of Tooling (D)] to Tooling (E). 12. Evenly, pull the front track roller frame into the rear track roller frame using Tooling (D) and (E). Make sure the grooves in the front track roller frame are aligned with the guide locations. Remove Tooling (D) and (E). 13. Install the bolts that hold the front idler caps and tighten them to a torque of 475 50 N m (350 37 lb ft). NOTE: Install guide (5) on the inside of the rear track roller frame first for easier installation. 14. Make sure the guide slots are aligned. Put the O-ring seals in position on the guides. Put guides (5) into the track roller frame and install the six bolts that hold each one. NOTE: The tracks must be installed and the correct track adjustment made before the oil level can be checked in the recoil spring compartment. 15. Fill the recoil spring compartment with oil to the correct level See the Operation And Maintenance Guide for the type and capacity of oil to be used. End By: https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 6/6 a. connect track Copyright 1993 - 2020 Caterpillar Inc. Mon Apr 27 12:11:26 UTC+0800 2020 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Eng... 1/11 Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D6R TRACK-TYPE TRACTOR 4HN Configuration: D6R Track-Type Tractor LGP 4HN00001-UP (MACHINE) POWERED BY 3306 Engine Disassembly and Assembly D6R TRACK-TYPE TRACTOR POWER TRAIN Media Number -SENR8357-02 Publication Date -01/05/2005 Date Updated -03/06/2014 SENR83570008 Recoil Springs SMCS - 4158-011; 4158-012 Remove Recoil Springs NOTE: All part numbers in this operation are part of Tooling (A), (B), (C), or (D). Start By: https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2020/4/27

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com