Caterpillar Cat D6N TRACK-TYPE TRACTOR (Prefix P5T) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

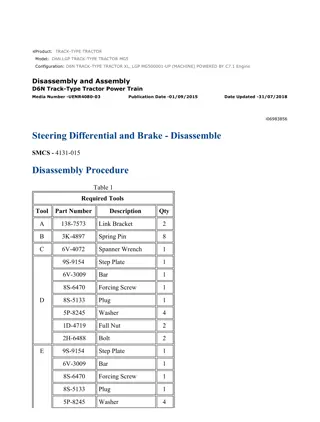

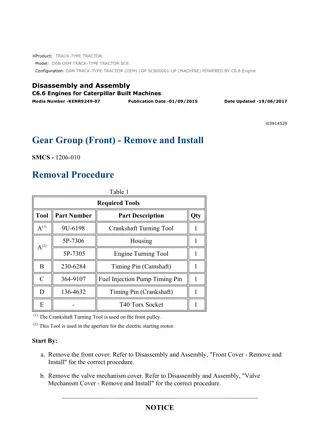

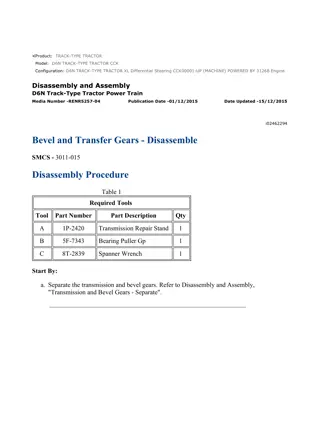

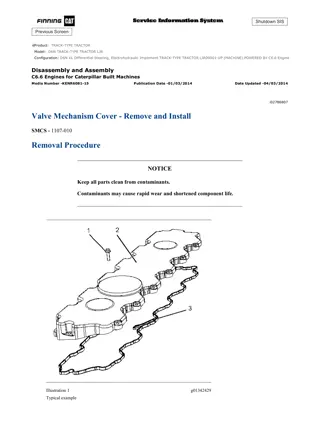

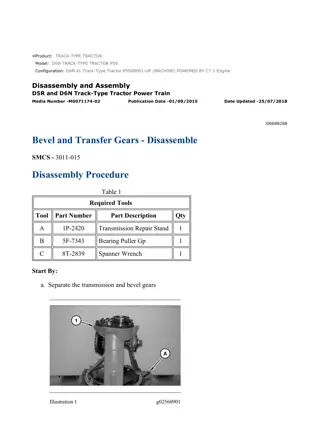

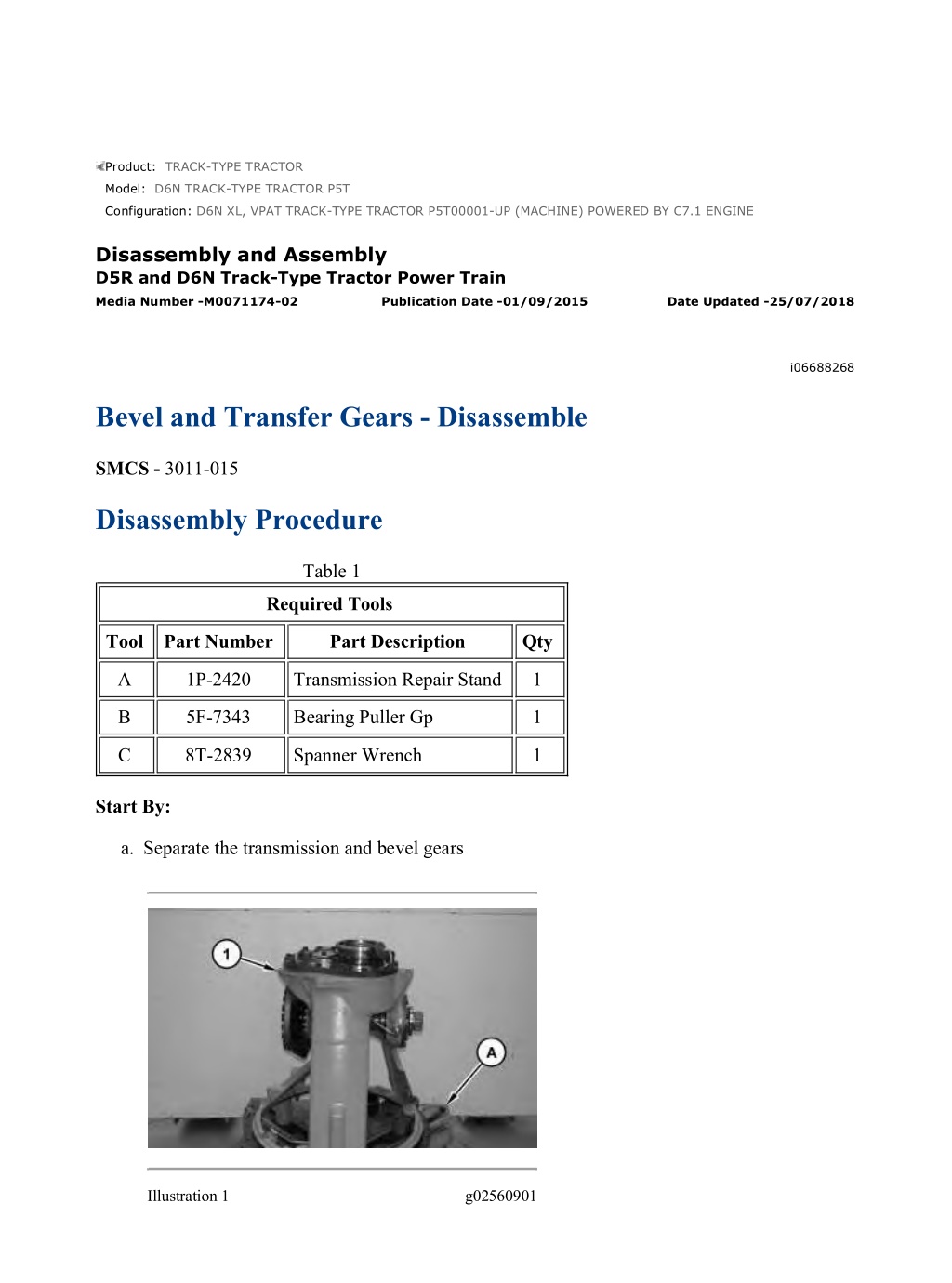

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 1/11 Product: TRACK-TYPE TRACTOR Model: D6N TRACK-TYPE TRACTOR P5T Configuration: D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED BY C7.1 ENGINE Disassembly and Assembly D5R and D6N Track-Type Tractor Power Train Media Number -M0071174-02 Publication Date -01/09/2015 Date Updated -25/07/2018 i06688268 Bevel and Transfer Gears - Disassemble SMCS - 3011-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-2420 Transmission Repair Stand 1 B 5F-7343 Bearing Puller Gp 1 C 8T-2839 Spanner Wrench 1 Start By: a. Separate the transmission and bevel gears Illustration 1 g02560901 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 2/11 1. Mount bevel and transfer gears (1) onto Tooling (A). Illustration 2 g02561261 2. Remove O-ring seals (3). 3. If necessary, remove pins (2). Illustration 3 g02561677 4. Remove guard (4), if installed, sensors (5), and bracket (6). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 3/11 Illustration 4 g02561822 5. Remove pulley (7). Remove cage (9) and shims (10). Note: Use two bolts (8) to remove cage (9). Illustration 5 g00994151 6. Remove O-ring seal (12), seal (11), bearing cone (14), and bearing cup (13) from cage (9). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 4/11 Illustration 6 g02561957 7. Remove bolts (15), cover (16), and shims (17). 8. Remove tube (17A). Illustration 7 g00954587 9. Remove bolts (18). Use two bolts (18) to remove cover (19). Tighten bolts (18) evenly and remove cover (19). Illustration 8 g00994154 10. If necessary, remove dowels (20) and bearing cup (21) from cover (19). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 5/11 Illustration 9 g00954590 11. Remove gear (22) and gear (23) from the case assembly. Illustration 10 g00954593 Note: Bearing cones (24) must be destroyed to remove the cones from the gear. 12. Remove bearing cones (24) from gear (22). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 6/11 Illustration 11 g00994158 13. Remove bolt (25) and retainer (26) from gear (23). Illustration 12 g00954591 14. Use Tooling (B) and a suitable press to remove bearing cone (27) from gear (28). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 7/11 Illustration 13 g00994331 15. Use a suitable press to remove bearing cone (29) from gear (28) and from gear (23). Illustration 14 g00954857 16. Remove bearing cups (30) from case (31). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 8/11 Illustration 15 g00994147 17. Bend the tab on lock ring (33) away from nut (32). Note: Use a new lock ring (33) during assembly. 18. Use Tooling (C) to remove nut (32). 19. Remove washer (34) and bearing cone (34A). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 9/11 Illustration 16 g01233575 20. Attach a suitable lifting device to shaft assembly (35). The weight of shaft assembly (35) is approximately 39 kg (86 lb). 21. Remove shaft assembly (35). Illustration 17 g00954861 22. Remove bolts (36) and gear (37). Illustration 18 g00954863 23. Remove race and roller bearing (38) from shaft assembly (35). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWER... 10/11 Illustration 19 g00994148 24. Remove bolts (39), cage (40), and shims (41). Illustration 20 g00994149 25. Remove bearing cone (46), bearing cups (45) and (42), and carrier (44). 26. Remove rings (43) from carrier (44). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWER... 11/11 Illustration 21 g00994563 27. Remove bearing cup (47) from case (31). Illustration 22 g00994564 28. Remove tube assemblies (49). Remove fittings (48), if necessary. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

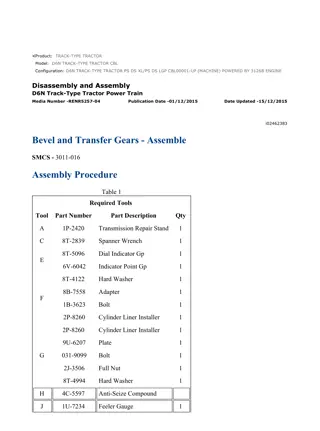

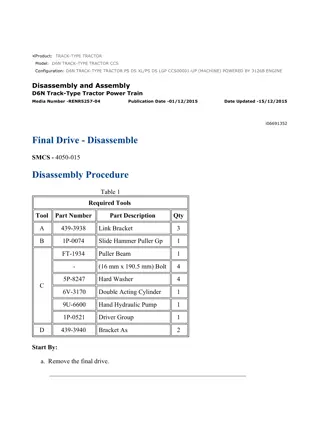

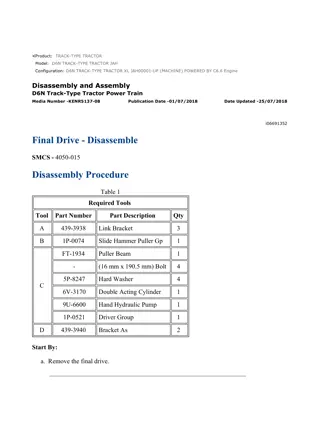

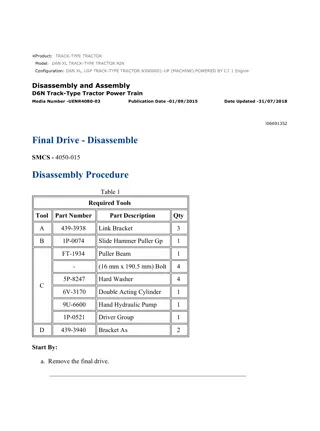

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 1/17 Product: TRACK-TYPE TRACTOR Model: D6N TRACK-TYPE TRACTOR P5T Configuration: D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED BY C7.1 ENGINE Disassembly and Assembly D5R and D6N Track-Type Tractor Power Train Media Number -M0071174-02 Publication Date -01/09/2015 Date Updated -25/07/2018 i06688220 Bevel and Transfer Gears - Assemble SMCS - 3011-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-2420 Transmission Repair Stand 1 C 8T-2839 Spanner Wrench 1 8T-5096 Dial Indicator Gp 1 E 6V-6042 Indicator Point Gp 1 8T-4122 Hard Washer 1 8B-7558 Adapter 1 F 1B-3623 Bolt 1 2P-8260 Cylinder Liner Installer 1 2P-8260 Cylinder Liner Installer 1 9U-6207 Plate 1 G 031-9099 Bolt 1 2J-3506 Full Nut 1 8T-4994 Hard Washer 1 H 4C-5597 Anti-Seize Compound J 1U-7234 Feeler Gauge 1 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 2/17 K 1P-0510 Driver Gp 1 L FT-2973 Holding Plate 1 M 5P-3413 Pipe Sealant NOTICE Keep all parts clean from contaminants. Contamination of the hydraulic system with foreign material will reduce the service life of the hydraulic system components. To prevent contaminants from entering the hydraulic system, always plug or cap the lines, fittings, or hoses as they are disconnected. Cover any disassembled components and clean them properly before assembly. Clean the hydraulic system properly after any major component exchange or especially after a component failure, to remove any contamination. Illustration 1 g00994564 1. Install fittings (48), if fittings (48) were removed. 2. Install tube assemblies (49). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 3/17 Illustration 2 g00994563 3. Lower the temperature of bearing cup (47). 4. Install bearing cup (47) into case (31). Illustration 3 g00994149 5. Install rings (43) into carrier (44). 6. Install carrier (44). 7. Lower the temperature of bearing cups (42) and (45). Install bearing cups (42) and (45). 8. Install bearing cone (46). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 4/17 Illustration 4 g00994148 9. Install original shims (41), cage (40), and bolts (39). Illustration 5 g00954863 10. Raise the temperature of race and roller bearing (38). 11. Install the race and roller bearing (38) onto shaft assembly (35). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 5/17 Illustration 6 g00954861 12. Position gear (37). Install bolts (36). Illustration 7 g01233575 13. Attach a suitable lifting device to shaft assembly (35). The weight of shaft assembly (35) is approximately 39 kg (86 lb). 14. Install shaft assembly (35). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 6/17 Illustration 8 g00994147 15. Install bearing cone (34A), washer (34), and new lock ring (33). 16. Apply Tooling (H) to the threads and to the face of nut (32). Install nut (32). 17. Use Tooling (C) in order to tighten nut (32) to a torque of 612 68 N m (451 50 lb ft). 18. Bend the tab on lock ring (33) toward nut (32). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 7/17 Illustration 9 g00954857 19. Lower the temperature of bearing cups (30). 20. Install bearing cups (30) into case (31). Illustration 10 g00971426 21. Raise the temperature of bearing cones (27) and (29). 22. Install bearing cone (27) onto gear (28). 23. Install gear (28) into gear (23). 24. Install bearing cone (29) onto gear (28). 25. Position retainer (26). 26. Install bolt (25). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 8/17 Illustration 11 g00954593 27. Raise the temperature of bearing cones (24). Install bearing cones (24) onto gear (22). Illustration 12 g00954590 Note: Gears (22) and (23) must be installed into the case assembly at the same time. 28. Install gear (22) and gear (23) into the case assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWERED... 9/17 Illustration 13 g00984442 29. Install bearing cup (21) into cover (19). Dimension (Z) is 4.30 mm (0.170 inch). Illustration 14 g00984467 30. Position cover (19). 31. Install dowels (20), if dowels (20) were removed. Install bolts (18). 32. Install bolt (25) and retainer (26). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWER... 10/17 Illustration 15 g00994324 33. Position shim (17) that is equal to 4.30 mm (0.169 inch) onto cover (19). 34. Install cover (16) and bolts (15). Illustration 16 g00984480 35. Install Tooling (E) and Tooling (F). 36. Rotate gear (28) in order to find the high spot on the face of bearing cone (29). 37. Zero Tooling (E). 38. Obtain an end play measurement. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWER... 11/17 39. Repeat Step 36 through Step 38 in order to ensure that an accurate measurement has been obtained. 40. Remove Tooling (E) and Tooling (F). Illustration 17 g00994324 41. Remove bolts (15) and cover (16). 42. Remove shims (17) in order to adjust the end play. The end play should be 0.080 0.050 mm (0.0031 0.0020 inch). 43. Install cover (16) and bolts (15). 44. Repeat Step 35 through Step 43 in order to ensure that an accurate measurement has been obtained. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWER... 12/17 Illustration 18 g00984518 45. Install retainer (26) and bolt (25). Illustration 19 g00973888 46. Lower the temperature of bearing cup (13). 47. Install O-ring seal (12) and bearing cup (13) onto cage (9). Illustration 20 g00954584 48. Install shims (10). Note: Allow clearance for the bearing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWER... 13/17 49. Install cage (9) and bolts (8). Illustration 21 g00994870 50. Use Tooling (G) and Tooling (E) to check the end play. 51. Rotate gear (22) to find the high spot on the face of bearing cone (24). 52. Zero Tooling (E). 53. Obtain an end play measurement. 54. Repeat Step 36 through Step 38 to ensure that an accurate measurement has been obtained. 55. Remove Tooling (E) and Tooling (G). Illustration 22 g00954584 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWER... 14/17 56. Remove bolts (8) and cage (9). 57. Add or remove shims (10), as required. 58. Install cage (9) and bolts (8). 59. Repeat Step 50 through Step 58 to ensure accuracy. Illustration 23 g00974756 60. Remove bolts (8) and cage (9). Illustration 24 g00974755 61. Lower the temperature of bearing (14). 62. Install bearing (14) into cage (9). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWER... 15/17 63. Apply Tooling (M) into the seal bore in cage (9). 64. Use Tooling (K) to install seal (11) into cage (9). Illustration 25 g00974756 65. Position cage (9). 66. Install bolts (8). Tighten bolts (8) to a torque of 135 15 N m (100 11 lb ft). Illustration 26 g00994736 67. Remove bolt (25). Install Tooling (L) and bolt (25). 68. Install Tooling (E). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

D6N XL, VPAT TRACK-TYPE TRACTOR P5T00001-UP (MACHINE) POWER... 16/17 69. Make three backlash measurements at 120 degrees intervals. The backlash should be 0.20 0.10 mm (0.008 0.004 inch). 70. Add or remove shims (42) to obtain the correct settings. Illustration 27 g00954581 71. Install bracket (6). 72. Install sensors (5). Use Tooling (J) to set the distance between the face of the sensors (5) and the gear teeth. The distance must be 0.71 0.18 mm (0.028 0.007 inch). Tighten the nut to a torque of 25 5 N m (18 4 lb ft). 73. Connect harness assemblies (7). Illustration 28 g00954580 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/12

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com