Caterpillar Cat D6N TRACK-TYPE TRACTOR (Prefix CBJ) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Service Repair Manual Models D6NTRACK-TYPE TRACTOR

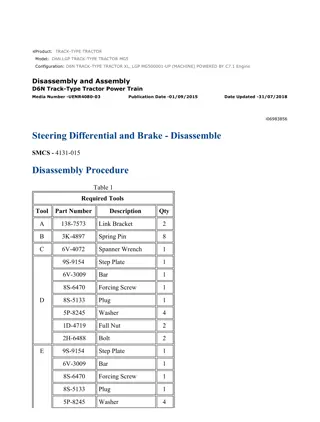

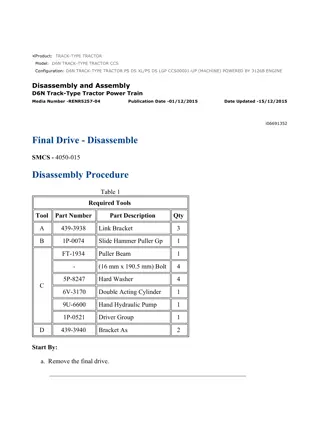

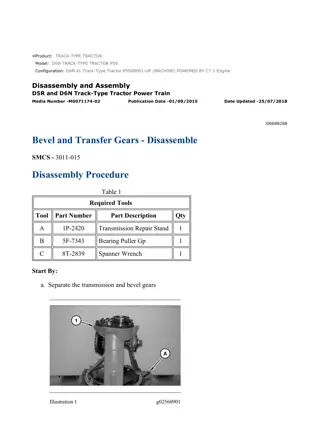

w 1/10(W) Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D6N TRACK-TYPE TRACTOR CBJ Configuration: D6N XL, FTC TRACK-TYPE TRACTOR CBJ00001-UP (MACHINE) POWERED BY 3126B Engine Disassembly and Assembly D6N Track-Type Tractor Power Train Media Number -RENR5267-00 Publication Date -01/04/2003 Date Updated -20/05/2003 i04780904 Torque Converter - Disassemble SMCS - 3101-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 5P-4758 Retaining Ring Pliers As 1 B 8H-0663 Bearing Puller Gp 1 C 8T-4172 Bolt 2 D 138-7573 Link Bracket 1 E 2P-8312 Retaining Ring Pliers 1 F 1P-0510 Driver Gp 1 G 1P-0520 Driver Gp 1 Start By: A. Remove the torque converter. Refer to Disassembly and Assembly, "Torque Converter- Remove". NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 2/10(W) before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. Illustration 1 g00964232 1. Remove lip seal (1) . Illustration 2 g00964235 2. Use Tooling (A) to remove retaining ring (2) . 3. Remove shaft assembly (3) from carrier assembly (4) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

w 3/10(W) Illustration 3 g00964237 4. Remove ring (5) . Illustration 4 g00964238 5. Use Tooling (B) and a suitable press to remove bearing (6) . Illustration 5 g00964240 6. Remove bolts (7) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 4/10(W) Illustration 6 g00964242 7. Install Tooling (C) . Tighten Tooling (C) in order to separate impeller assembly (8) and housing assembly (9) . Illustration 7 g00964244 8. Attach Tooling (D) and a suitable lifting device to impeller assembly (8) in order to reposition impeller assembly (8) . The weight of impeller assembly (8) is approximately 32 kg (70 lb). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 5/10(W) Illustration 8 g00964246 9. Use Tooling (E) to remove retaining ring (10) . Illustration 9 g00964248 10. Remove stator (11) . Note: For torque converters with a two piece stator refer to steps 11 and 12. For torque converters with a one piece stator, disregard steps 11 and 12. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 6/10(W) Illustration 10 g00964250 11. Remove retaining rings (12) from both sides of stator (11) . Illustration 11 g00964252 12. Use Tooling (F) and a suitable press to remove adapter (13) from stator (11) . Illustration 12 g00964586 13. Use Tooling (E) to remove retaining ring (14) . Remove spacer (15) from carrier assembly (4) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 7/10(W) Illustration 13 g00964254 14. Use a suitable press to remove carrier assembly (4) from impeller assembly (8) . Illustration 14 g00964258 15. Remove ring (16) from carrier assembly (4) . Illustration 15 g00964259 16. Remove bolts (17) and pump drive gear (18) from impeller (19) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 8/10(W) Illustration 16 g00964261 17. Use Tooling (G) and a suitable press to remove bearing (20) from impeller (19) . Illustration 17 g00964264 18. Remove retaining ring (21) and cover (22) from housing (9) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 9/10(W) Illustration 18 g00964266 19. Use Tooling (E) to remove retaining ring (24) from housing (9) . Remove spacer (25) and O -ring seal (23) from housing (9) . Illustration 19 g00964268 20. Remove ring (27) . Use a suitable press to remove hub assembly (26) from housing (9) . Illustration 20 g00964273 21. Use Tooling (G) and a suitable press to remove bearing (28) (not shown) from housing (9) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 10/10(W) Illustration 21 g00964280 22. Remove bolts (29) from turbine (30) . Remove hub (31) . Copyright 1993 - 2021 Caterpillar Inc. Thu Dec 2 10:19:14 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 1/10(W) Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D6N TRACK-TYPE TRACTOR CBJ Configuration: D6N XL, FTC TRACK-TYPE TRACTOR CBJ00001-UP (MACHINE) POWERED BY 3126B Engine Disassembly and Assembly D6N Track-Type Tractor Power Train Media Number -RENR5267-00 Publication Date -01/04/2003 Date Updated -20/05/2003 i04781455 Torque Converter - Assemble SMCS - 3101-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 5P-4758 Retaining Ring Pliers As 1 B 8H-0663 Bearing Puller Gp 1 C 8T-4172 Bolt 2 D 138-7573 Link Bracket 1 E 2P-8312 Retaining Ring Pliers 1 F 1P-0510 Driver Gp 1 G 1P-0520 Driver Gp 1 H 5P-3413 Pipe Sealant 1 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 2/10(W) Illustration 1 g00964280 1. Install hub (31) . Install bolts (29) on turbine (30) . Tighten bolts (29) to a torque of 60 7 N m (44 5 lb ft). Illustration 2 g00968220 2. Lower temperature of bearing (28) . Install bearing (28) in housing (9) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 3/10(W) Illustration 3 g00974926 3. Lower the temperature of hub assembly (26) . Install hub assembly (26) on housing (9) . Install ring (27) (not shown). Illustration 4 g00964266 4. Install O-ring seal (23) and spacer (25) on housing (9) . Use Tooling (E) to install retaining ring (24) on housing (9) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 4/10(W) Illustration 5 g00964264 5. Install cover (22) on housing (9) . Install retaining ring (21) . Illustration 6 g00974928 6. Lower the temperature of bearing (20) . Install bearing (20) on impeller (19) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 5/10(W) Illustration 7 g00964259 7. Install pump drive gear (18) and bolts (17) on impeller (19) . Tighten bolts (17) to a torque of 105 15 N m (77 11 lb ft). Illustration 8 g00964258 8. Install ring (16) on carrier assembly (4) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 6/10(W) Illustration 9 g00974930 9. Lower the temperature of carrier assembly (4) . Install carrier assembly (4) on impeller assembly (8) . Note: The dowel in carrier assembly (4) must align with the notch in the bearing. Illustration 10 g00964586 10. Install spacer (15) on carrier assembly (4) . Use Tooling (E) to install retaining ring (14) . Note: For torque converters with a one piece stator, disregard step 11. For torque converters with a two piece stator, refer to step 11. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 7/10(W) Illustration 11 g00975119 11. Install retaining ring (12) on stator (11) . Lower the temperature of adapter (13) and raise the temperature of stator (11) . Install adapter (13) into stator (11) . Install the remaining retaining ring (12) on the opposite side of stator (11) . Illustration 12 g00964248 12. Install stator (11) . Illustration 13 g00964246 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 8/10(W) 13. Use Tooling (E) to install retaining ring (10) . Illustration 14 g00970336 14. Attach Tooling (D) and a suitable lifting device to impeller assembly (8) in order to position impeller assembly (8) on housing assembly (9) . The weight of impeller assembly (8) is approximately 32 kg (70 lb). Illustration 15 g00964240 15. Install bolts (7) . Tighten bolts (7) to a torque of 60 7 N m (44 5 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 9/10(W) Illustration 16 g00964238 16. Use Tooling (B) and a suitable press to install bearing (6) . Illustration 17 g00964237 17. Install ring (5) . Illustration 18 g00964235 18. Install shaft assembly (3) into carrier assembly (4) . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 10/10(W) 19. Use Tooling (A) to install retaining ring (2) . Illustration 19 g00964232 20. Apply Tooling (H) to the bore and install lip seal (1) within 0.63 mm (0.025 inch) of the surface. End By: Install the torque converter. Refer to Disassembly and Assembly, "Torque Converter- Install". Copyright 1993 - 2021 Caterpillar Inc. Thu Dec 2 10:20:10 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 1/7(W) Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D6N TRACK-TYPE TRACTOR CBJ Configuration: D6N XL, FTC TRACK-TYPE TRACTOR CBJ00001-UP (MACHINE) POWERED BY 3126B Engine Disassembly and Assembly D6N Track-Type Tractor Power Train Media Number -RENR5267-00 Publication Date -01/04/2003 Date Updated -20/05/2003 i01880999 Torque Converter - Install SMCS - 3101-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 8T-0355 Bolt 4 B 138-7573 Link Bracket 1 C 8T-4196 Bolt 2 D 138-7575 Link Bracket 2 F 155-0695 Thread Lock Compound Note: Cleanliness is an important factor. Before assembly, all parts should be thoroughly cleaned in cleaning fluid. Allow the parts to air dry. Wiping cloths or rags should not be used to dry parts. Lint may be deposited on the parts which may cause later trouble. Inspect all parts. If any parts are worn or damaged, use new parts for replacement. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 2/7(W) Illustration 1 g00973901 1. Use Tooling (D) and a suitable lifting device to position torque converter housing (11) onto torque converter (19). The weight of torque converter housing (11) is approximately 154 kg (340 lb). Illustration 2 g00970170 2. Install bolts (18). Tighten bolts (18) to a torque of 55 10 N m (41 7 lb ft). Illustration 3 g00970168 3. Install sensor (17), yoke (16), retainer (15), and bolt (14). Tighten bolts (14) to a torque of 105 15 N m (77 11 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 3/7(W) Illustration 4 g00973959 4. Attach Tooling (B) and a suitable lifting device to torque converter housing (11). Raise torque converter housing (11). The weight of torque converter housing (11) is approximately 154 kg (340 lb). Install Tooling (A) in order to support torque converter housing (11). Illustration 5 g00974379 5. Align torque converter housing (11) to flywheel housing (13). Illustration 6 g00970161 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 4/7(W) 6. Apply Tooling (F) to bolts (12). Install bolts (12). Tighten bolts (12) to a torque of 55 10 N m (41 7 lb ft). Illustration 7 g00970159 7. Remove Tooling (B) and the suitable lifting device from torque converter housing (11). Illustration 8 g00970157 Illustration 9 g00970155 8. Remove Tooling (A) and install bolts (10). Tighten bolts (10) to a torque of 55 10 N m (41 7 lb ft). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 5/7(W) Illustration 10 g00970150 9. Install bolt (9). Illustration 11 g00970146 10. Connect hose (8). Illustration 12 g00970142 11. Install bolt (7). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 6/7(W) Illustration 13 g00970138 12. Install bolt (6). Illustration 14 g00970134 13. Connect harness assemblies (5). Illustration 15 g00970129 14. Install bolts (3) that retain harness assembly (4). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 7/7(W) Illustration 16 g00970125 15. Connect hose assemblies (2). Illustration 17 g00970122 16. Connect hose assembly (1). End By: a. Install the power train oil pump. Refer to Disassembly and Assembly, "Power Train Oil Pump - Install". b. Install the piston pump (implement). Refer to Disassembly and Assembly, "Piston Pump (Implement) - Install". c. Install the main drive shaft. Refer to Disassembly and Assembly, "Main Drive Shaft - Remove and Install". Copyright 1993 - 2021 Caterpillar Inc. Thu Dec 2 10:21:06 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

w 1/3(W) Shutdown SIS Previous Screen Product: TRACK-TYPE TRACTOR Model: D6N TRACK-TYPE TRACTOR CBJ Configuration: D6N XL, FTC TRACK-TYPE TRACTOR CBJ00001-UP (MACHINE) POWERED BY 3126B Engine Disassembly and Assembly D6N Track-Type Tractor Power Train Media Number -RENR5267-00 Publication Date -01/04/2003 Date Updated -20/05/2003 i02462805 Torque Converter Outlet Relief Valve - Remove SMCS - 3133-011 Removal Procedure NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. Note: Cleanliness is an important factor. Before you begin the removal procedure, the exterior of the components should be thoroughly cleaned. This will help to prevent dirt from entering the internal mechanism. Note: Put identification marks on all hoses, on all hose assemblies, on all wires, and on all tube assemblies for installation purposes. Plug all hose assemblies and all tube assemblies. This helps to prevent fluid loss, and this helps to keep contaminants from entering the system. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

w 2/3(W) Illustration 1 g00975751 1. Remove floorplate (1). Illustration 2 g00975868 2. Remove bolts (2). Disconnect hose assemblies (3). Illustration 3 g00975871 3. Remove bolts (4). Remove relief valve (5). Copyright 1993 - 2021 Caterpillar Inc. Thu Dec 2 10:22:02 UTC+0800 2021 All Rights Reserved. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisw... 2021/12/2

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com