Caterpillar Cat D6N TRACK-TYPE TRACTOR (Prefix CBL) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

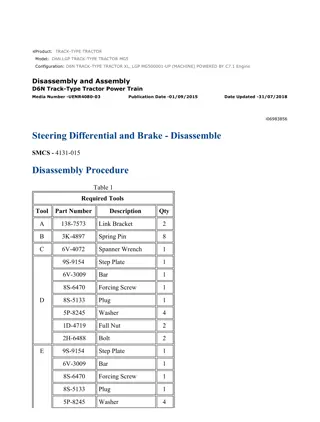

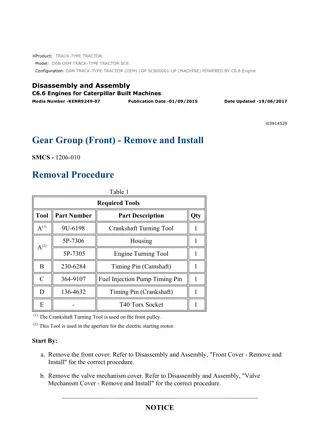

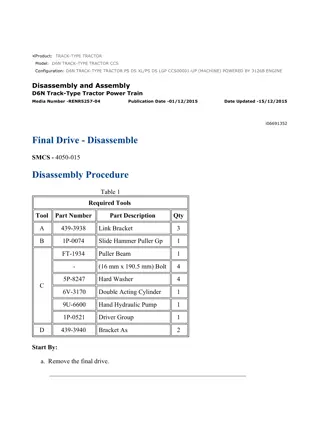

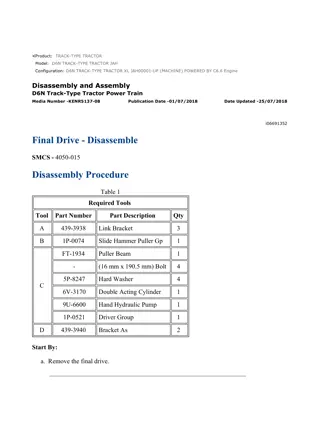

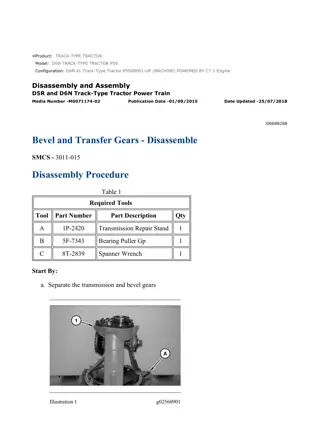

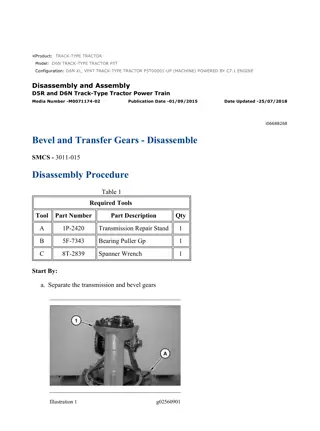

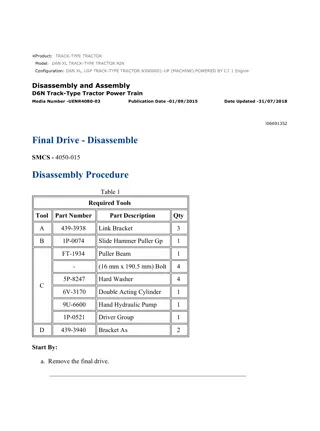

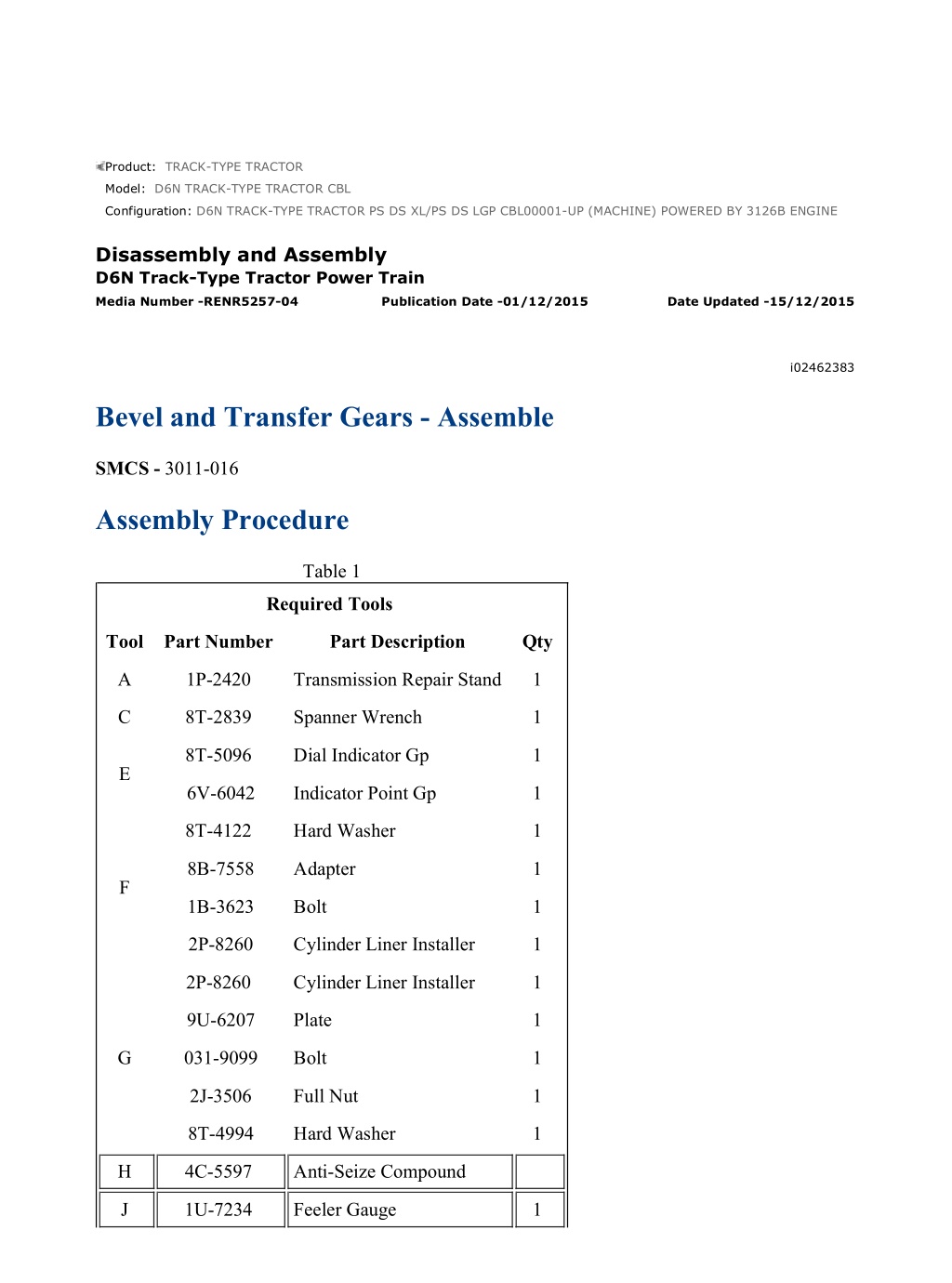

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 1/18 Product: TRACK-TYPE TRACTOR Model: D6N TRACK-TYPE TRACTOR CBL Configuration: D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE) POWERED BY 3126B ENGINE Disassembly and Assembly D6N Track-Type Tractor Power Train Media Number -RENR5257-04 Publication Date -01/12/2015 Date Updated -15/12/2015 i02462383 Bevel and Transfer Gears - Assemble SMCS - 3011-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-2420 Transmission Repair Stand 1 C 8T-2839 Spanner Wrench 1 8T-5096 Dial Indicator Gp 1 E 6V-6042 Indicator Point Gp 1 8T-4122 Hard Washer 1 8B-7558 Adapter 1 F 1B-3623 Bolt 1 2P-8260 Cylinder Liner Installer 1 2P-8260 Cylinder Liner Installer 1 9U-6207 Plate 1 G 031-9099 Bolt 1 2J-3506 Full Nut 1 8T-4994 Hard Washer 1 H 4C-5597 Anti-Seize Compound J 1U-7234 Feeler Gauge 1 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

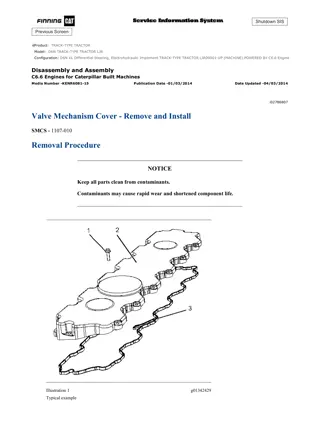

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 2/18 K 1P-0510 Driver Gp 1 L FT-2973 Holding Plate 1 M 5P-3413 Pipe Sealant NOTICE Keep all parts clean from contaminants. Contamination of the hydraulic system with foreign material will reduce the service life of the hydraulic system components. To prevent contaminants from entering the hydraulic system, always plug or cap the lines, fittings, or hoses as they are disconnected. Cover any disassembled components and clean them properly before assembly. Clean the hydraulic system properly after any major component exchange or especially after a component failure, to remove any contamination. Illustration 1 g00994564 1. Install fittings (48), if fittings (48) were removed. 2. Install tube assemblies (49). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 3/18 Illustration 2 g00994563 3. Lower the temperature of bearing cup (47). 4. Install bearing cup (47) into case (31). Illustration 3 g00994149 5. Install rings (43) into carrier (44). 6. Install carrier (44). 7. Lower the temperature of bearing cups (42) and (45). Install bearing cups (42) and (45). 8. Install bearing cone (46). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 4/18 Illustration 4 g00994148 9. Install original shims (41), cage (40), and bolts (39). Illustration 5 g00954863 10. Raise the temperature of race and roller bearing (38). 11. Install the race and roller bearing (38) onto shaft assembly (35). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 5/18 Illustration 6 g00954861 12. Position gear (37). Install bolts (36). Illustration 7 g01233575 13. Attach a suitable lifting device to shaft assembly (35). The weight of shaft assembly (35) is approximately 39 kg (86 lb). 14. Install shaft assembly (35). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 6/18 Illustration 8 g00994147 15. Install bearing cone (34A), washer (34), and new lock ring (33). 16. Apply Tooling (H) to the threads and to the face of nut (32). Install nut (32). 17. Use Tooling (C) in order to tighten nut (32) to a torque of 612 68 N m (451 50 lb ft). 18. Bend the tab on lock ring (33) toward nut (32). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 7/18 Illustration 9 g00954857 19. Lower the temperature of bearing cups (30). 20. Install bearing cups (30) into case (31). Illustration 10 g00971426 21. Raise the temperature of bearing cones (27) and (29). 22. Install bearing cone (27) onto gear (28). 23. Install gear (28) into gear (23). 24. Install bearing cone (29) onto gear (28). 25. Position retainer (26). 26. Install bolt (25). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 8/18 Illustration 11 g00954593 27. Raise the temperature of bearing cones (24). Install bearing cones (24) onto gear (22). Illustration 12 g00954590 Note: Gears (22) and (23) must be installed into the case assembly at the same time. 28. Install gear (22) and gear (23) into the case assembly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 9/18 Illustration 13 g00984442 29. Install bearing cup (21) into cover (19). Dimension (Z) is 4.30 mm (0.170 inch). Illustration 14 g00984467 30. Position cover (19). 31. Install dowels (20), if dowels (20) were removed. Install bolts (18). 32. Install bolt (25) and retainer (26). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHIN... 10/18 Illustration 15 g00994324 33. Position shim (17) that is equal to 4.30 mm (0.169 inch) onto cover (19). 34. Install cover (16) and bolts (15). Illustration 16 g00984480 35. Install Tooling (E) and Tooling (F). 36. Rotate gear (28) in order to find the high spot on the face of bearing cone (29). 37. Zero Tooling (E). 38. Obtain an end play measurement. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHIN... 11/18 39. Repeat Step 36 through Step 38 in order to ensure that an accurate measurement has been obtained. 40. Remove Tooling (E) and Tooling (F). Illustration 17 g00994324 41. Remove bolts (15) and cover (16). 42. Remove shims (17) in order to adjust the end play. The end play should be 0.080 0.050 mm (0.0031 0.0020 inch). 43. Install cover (16) and bolts (15). 44. Repeat Step 35 through Step 43 in order to ensure that an accurate measurement has been obtained. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHIN... 12/18 Illustration 18 g00984518 45. Install retainer (26) and bolt (25). Illustration 19 g00973888 46. Lower the temperature of bearing cup (13). 47. Install O-ring seal (12) and bearing cup (13) onto cage (9). Illustration 20 g00954584 48. Install shims (10). Note: Allow clearance for the bearing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHIN... 13/18 49. Install cage (9) and bolts (8). Illustration 21 g00994870 50. Use Tooling (G) and Tooling (E) in order to check the end play. 51. Rotate gear (22) in order to find the high spot on the face of bearing cone (24). 52. Zero Tooling (E). 53. Obtain an end play measurement. 54. Repeat Step 36 through Step 38 in order to ensure that an accurate measurement has been obtained. 55. Remove Tooling (E) and Tooling (G). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHIN... 14/18 Illustration 22 g00954584 56. Remove bolts (8) and cage (9). 57. Add or remove shims (10), as required. 58. Install cage (9) and bolts (8). 59. Repeat Step 50 through Step 58 in order to ensure accuracy. Illustration 23 g00974756 60. Remove bolts (8) and cage (9). Illustration 24 g00974755 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHIN... 15/18 61. Lower the temperature of bearing (14). 62. Install bearing (14) into cage (9). 63. Apply Tooling (M) into the seal bore in cage (9). 64. Use Tooling (K) in order to install seal (11) into cage (9). Illustration 25 g00974756 65. Position cage (9). 66. Install bolts (8). Tighten bolts (8) to a torque of 135 15 N m (100 11 lb ft). Illustration 26 g00994736 67. Remove bolt (25). Install Tooling (L) and bolt (25). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHIN... 16/18 68. Install Tooling (E). 69. Make three backlash measurements at 120 degrees intervals. The backlash should be 0.20 0.10 mm (0.008 0.004 inch). 70. Add or remove shims (42) in order to obtain the correct settings. Illustration 27 g00954581 71. Install bracket (6). 72. Install sensors (5). Use Tooling (J) in order to set the distance between the face of the sensors (5) and the gear teeth. The distance must be 0.71 0.18 mm (0.028 0.007 inch). Tighten the nut to a torque of 25 5 N m (18 4 lb ft). 73. Connect harness assemblies (7). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHIN... 17/18 Illustration 28 g00954580 74. Install pins (3), if pins (3) have been removed. 75. Install O-ring seals (4). Illustration 29 g00954579 76. Install bracket assemblies (2). Illustration 30 g00959670 77. Remove bevel and transfer gears (1) from Tooling (A). End By: a. Connect the transmission and bevel gears. Refer to Disassembly and Assembly, "Transmission and Bevel Gears - Connect". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 1/25 Product: TRACK-TYPE TRACTOR Model: D6N TRACK-TYPE TRACTOR CBL Configuration: D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE) POWERED BY 3126B ENGINE Disassembly and Assembly D6N Track-Type Tractor Power Train Media Number -RENR5257-04 Publication Date -01/12/2015 Date Updated -15/12/2015 i02461619 Transmission - Disassemble SMCS - 3030-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 1P-1864 Retaining Ring Pliers 1 B 136-1452 Retaining Ring Pliers 1 C 9U-7480 Compressing Tube 1 D 1P-1863 Retaining Ring Pliers 1 E 138-7573 Link Bracket 2 Start By: a. Separate the transmission and bevel gear. Refer to Disassembly and Assembly, "Transmission and Bevel Gear - Seperate". NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 2/25 Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. Note: Cleanliness is an important factor. Before you begin the disassembly procedure, the exterior of the components should be thoroughly cleaned. This will help to prevent dirt from entering the internal mechanism. Precision components can be damaged by contaminants or by dirt. Perform disassembly procedures on a clean work surface. Keep components covered and protected at all times. Illustration 1 g00970309 1. Remove four bolts (1A). 2. Remove transmission hydraulic control valve (1B). Illustration 2 g00960277 3. Loosen nuts (2). 4. Remove sensors (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 3/25 Illustration 3 g00960279 5. Use Tooling (A) in order to remove retaining ring (3). Illustration 4 g00960280 6. Remove bolts (4) and housing (5). Illustration 5 g00960281 7. Remove ring (6) and bearing (7) from housing (5). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 4/25 Illustration 6 g00960282 8. Remove springs (8), discs (9), and plates (10). Illustration 7 g00960283 9. Remove piston (11). Illustration 8 g00960286 10. Remove seals (12) from piston (11). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 5/25 Illustration 9 g01228398 11. Attach Tooling (E) and a suitable lifting device to housing assembly (13). 12. Apply slight lifting pressure. 13. Use Tooling (B) in order to compress retaining ring (14). Remove housing assembly (13). Illustration 10 g00960289 14. Remove retaining ring (14) and seals (15) from housing assembly (13). Illustration 11 g01228395 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 6/25 Illustration 12 g00960293 Personal injury can result from being struck by parts propelled by a released spring force. Make sure to wear all necessary protective equipment. Follow the recommended procedure and use all recommended tooling to release the spring force. 15. Use a suitable press and Tooling (C) in order to remove ring (16). Illustration 13 g00960295 16. Remove plate (17) and springs (18). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 7/25 Illustration 14 g00960298 17. Remove housing assembly (13) from coupling (19). Illustration 15 g00960300 18. Remove piston (20) from housing assembly (13). Illustration 16 g00960299 19. Remove seals (21) from piston (20). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 8/25 Illustration 17 g00960301 20. Use Tooling (D) in order to remove retaining ring (22). 21. Remove gear (23). Illustration 18 g00960302 22. Remove discs (24) and plates (25). Illustration 19 g00960304 23. Remove gear (26). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHINE)... 9/25 Illustration 20 g00960305 24. Remove ring (27) and plate (28). Illustration 21 g00960307 25. Remove housing (29). Illustration 22 g00960308 26. Remove piston (30) from housing (29). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHIN... 10/25 Illustration 23 g00960315 27. Remove seals (31) from piston (30). Illustration 24 g00960316 28. Remove plate (32) and discs (34). Remove springs (33). Illustration 25 g00960317 29. Remove carrier assembly (35). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CBL00001-UP (MACHIN... 11/25 Illustration 26 g00960320 30. Remove ring (36) from carrier assembly (35). Illustration 27 g00960322 31. Compress ring (37) in order to remove gear (38) from carrier assembly (35). Illustration 28 g00960323 32. Remove ring (37) from carrier assembly (35). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/11/11

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com