Caterpillar Cat D6N TRACK-TYPE TRACTOR (Prefix CCS) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

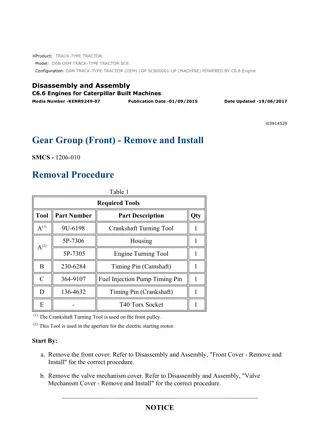

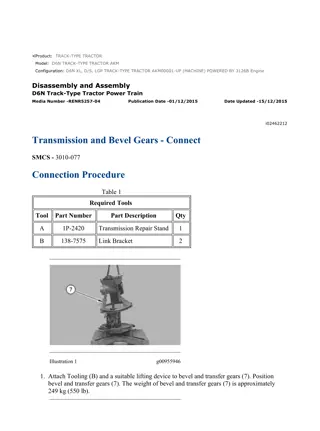

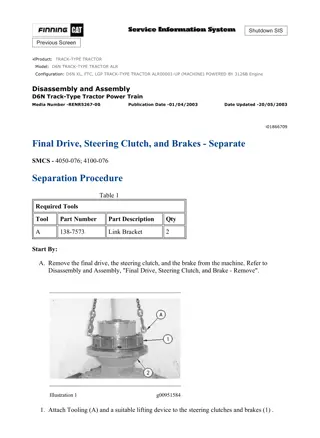

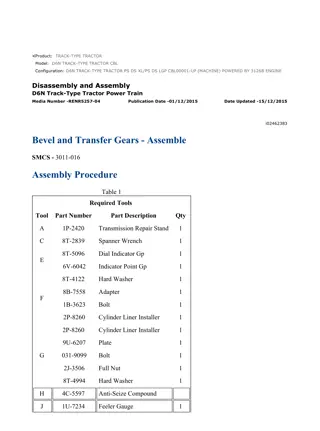

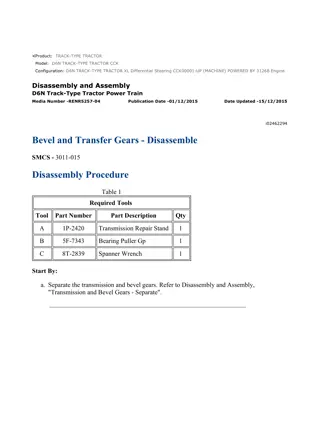

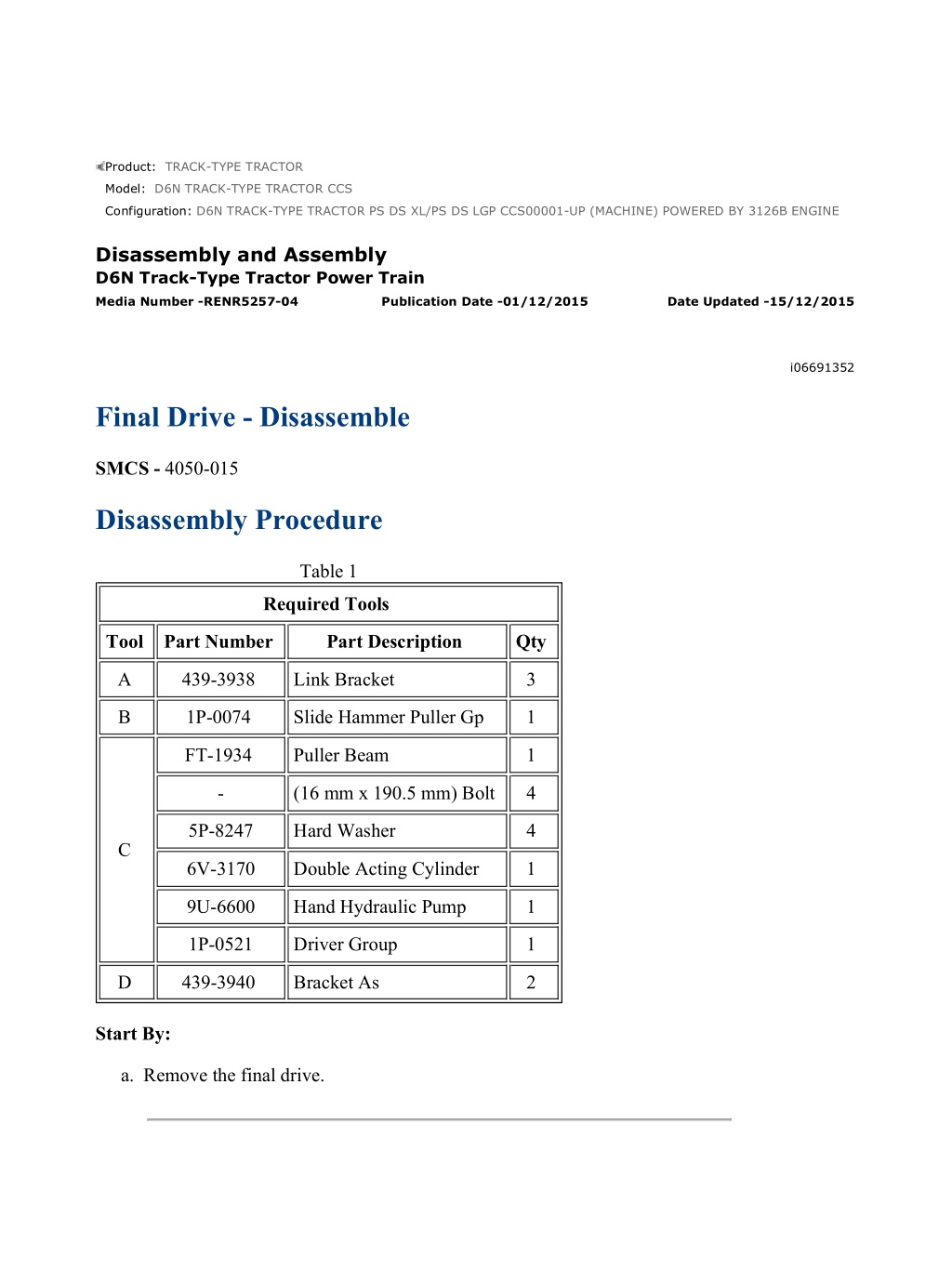

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 1/6 Product: TRACK-TYPE TRACTOR Model: D6N TRACK-TYPE TRACTOR CCS Configuration: D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE) POWERED BY 3126B ENGINE Disassembly and Assembly D6N Track-Type Tractor Power Train Media Number -RENR5257-04 Publication Date -01/12/2015 Date Updated -15/12/2015 i06691352 Final Drive - Disassemble SMCS - 4050-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 439-3938 Link Bracket 3 B 1P-0074 Slide Hammer Puller Gp 1 FT-1934 Puller Beam 1 - (16 mm x 190.5 mm) Bolt 4 5P-8247 Hard Washer 4 C 6V-3170 Double Acting Cylinder 1 9U-6600 Hand Hydraulic Pump 1 1P-0521 Driver Group 1 D 439-3940 Bracket As 2 Start By: a. Remove the final drive. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 2/6 Illustration 1 g01234745 1. Attach Tooling (A) and a suitable lifting device to carrier (1). The weight of carrier (1) is approximately 50 kg (110 lb). 2. Remove bolts (2) and carrier (1) from sprocket hub (3). Position carrier (1) onto suitable cribbing. Illustration 2 g01234760 3. Remove bolt (4), the washer, the retainer, and the O-ring seal from carrier (1). 4. Use a suitable press to remove shaft (5) from carrier (1). 5. Repeat Steps 3 and 4 for the remaining shafts. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 3/6 Illustration 3 g06077476 6. Remove planetary gear (8) from carrier (1). 7. Remove bearing cones (6) and (9) from planetary gear (8). 8. Remove bearing cups (7) from planetary gear (8). 9. Repeat Steps 6 through 8 for the remaining planetary gears. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 4/6 Illustration 4 g00988981 10. Remove bolts (10) and retainer (11). 11. Remove ring gear hub (12) and ring gear (13). Illustration 5 g00988984 12. Remove ring (14) and ring gear hub (12) from ring gear (13). Illustration 6 g00988985 13. Use Tooling (B) to remove bushing (15) and lip-type seal (16) (not shown). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 5/6 Illustration 7 g00988979 14. Raise the temperature of bearing cone (17). 15. Use Tooling (C) to remove bearing cone (17) from the spindle. Note: Do not lift the sprocket hub so that the sprocket hub contacts the fittings that are on the hydraulic cylinder. Damage to the fittings could occur. 16. Remove Tooling (C). Illustration 8 g01235181 17. Attach Tooling (D) and a suitable lifting device to sprocket hub (3). The weight of sprocket hub (3) is approximately 135 kg (298 lb). Remove sprocket hub (3) from the spindle. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 6/6 Illustration 9 g01235238 18. Remove bearing cups (18) and (19) from sprocket hub (3). 19. Remove Duo-cone seal (20) from sprocket hub (3). Illustration 10 g01235241 20. Remove Duo-cone seal (22) from spindle (23). 21. Remove bearing cone (21) from spindle (23). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 1/7 Product: TRACK-TYPE TRACTOR Model: D6N TRACK-TYPE TRACTOR CCS Configuration: D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE) POWERED BY 3126B ENGINE Disassembly and Assembly D6N Track-Type Tractor Power Train Media Number -RENR5257-04 Publication Date -01/12/2015 Date Updated -15/12/2015 i03902166 Final Drive - Assemble SMCS - 4050-016 Assembly Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 138-7573 Link Bracket 3 D 138-7575 Link Bracket 2 E 1P-0520 Driver Gp 1 169-0503 Installation Kit 1 F 8M-9395 Seal Installer 1 G 1U-7234 Feeler Gauge 1 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 2/7 Illustration 1 g01235241 1. Raise the temperature of bearing cone (21). Install bearing cone (21) onto spindle (23). 2. Use Tooling (F) (not shown) in order to install Duo-cone seal (22). Refer to Disassembly and Assembly, "Duo-Cone Conventional Seals - Install". Illustration 2 g01235238 3. Lower the temperature of bearing cups (19) and (18). 4. Install bearing cups (19) and (18) in hub (3). 5. Use Tooling (F) (not shown) in order to install Duo-cone seal (20) in hub (3). Refer to Disassembly and Assembly, "Duo-Cone Conventional Seals - Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 3/7 Illustration 3 g01235181 6. Install Tooling (D) and a suitable lifting device to hub (3). Install hub (3) onto the spindle. The weight of hub (3) is approximately 135 kg (298 lb). Illustration 4 g00990323 7. Install lip seal (16) and sleeve bearing (15). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 4/7 Illustration 5 g00988984 8. Position hub (12) onto gear (13). Install ring (14). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 5/7 Illustration 6 g02145273 9. Raise the temperature of bearing cone (17). Install bearing cone (17) on the spindle. 10. Install hub (12) and gear (13) as an assembly. 11. Install retainer (11) and bolts (10). Tighten all bolts (10) in a star pattern. Tighten bolts (10) to a torque of 120 20 N m (89 15 lb ft). Continually rotate hub (12) in order to properly seat bearing cone (17). Tighten bolts (10) to a torque of 120 20 N m (89 15 lb ft) in order to ensure the proper torque. 12. Use Tooling (G) (not shown) in order to verify that the spindle is touching the retainer. 13. If necessary, repeat Step 11 and Step 12 in order to verify that bearing cone (17) is seated properly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 6/7 Illustration 7 g01234812 14. Lower the temperature of bearing cups (7). Install bearing cups (7) into gear (8). 15. Position bearing cones (6) and (9) into gear (8). 16. Position gear (8) into carrier (1). Illustration 8 g01235164 17. Lower the temperature of shaft (5). Use a suitable press in order to install shaft (5). Install shaft (5) until the end of the shaft is flush with the outer surface of carrier (1). 18. Install bolt (4) and the plate to carrier (1). 19. Verify that there is metal to metal contact between plates (4) and the shafts. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 7/7 20. Repeat Steps 17 through 19 for the remaining shafts. Illustration 9 g01234745 21. Attach Tooling (A) to carrier (1). Position carrier (1) into hub (3). The weight of carrier (1) is approximately 41 kg (90 lb). 22. Install bolts (2). 23. Remove Tooling (A). End By: a. Install the final drive. Refer to Disassembly and Assembly, "Final Drive - Install". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 1/3 Product: TRACK-TYPE TRACTOR Model: D6N TRACK-TYPE TRACTOR CCS Configuration: D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE) POWERED BY 3126B ENGINE Disassembly and Assembly D6N Track-Type Tractor Power Train Media Number -RENR5257-04 Publication Date -01/12/2015 Date Updated -15/12/2015 i01896906 Final Drive - Install SMCS - 4050-012 Installation Procedure Table 1 Required Tools Tool Part Number Part Description Qty 8T-3207 Lifting Bracket 1 5P-8622 Shackle 1 A 9S-9076 Spacer 1 7X-2557 Bolt 2 Illustration 1 g00956633 1. Adjust bracket (1) until Dimension (X) is equal to 80 mm (3.0 inch). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 2/3 Illustration 2 g00986693 Illustration 3 g00986856 2. Attach Tooling (A) and a suitable lifting device to final drive (3). 3. Install bolts (4) and bolts (5). 4. Remove Tooling (A). Illustration 4 g00986692 5. Install bolts (2). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 3/3 End By: a. Install the axle. Refer to Disassembly and Assembly, "Axle - Install". b. Connect the track. Refer to Disassembly and Assembly, "Track - Connect". https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 1/5 Product: TRACK-TYPE TRACTOR Model: D6N TRACK-TYPE TRACTOR CCS Configuration: D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE) POWERED BY 3126B ENGINE Disassembly and Assembly D6N Track-Type Tractor Power Train Media Number -RENR5257-04 Publication Date -01/12/2015 Date Updated -15/12/2015 i01905492 Final Drive, Steering Differential, and Brake (Left Side) - Remove SMCS - 4050-011-LT; 4131-011 Removal Procedure Table 1 Required Tools Tool Part Number Part Description Qty A 154-6181 Forcing Screw 3 B 8T-3207 Lifting Bracket 1 C 138-7575 Link Bracket 1 D 8S-9906 Ratchet Puller 1 Start By: a. Separate the track. Refer to Disassembly and Assembly, "Track - Separate". b. Remove the steering motor. Refer to Disassembly and Assembly, "Steering Motor - Remove". c. Remove the axles. Refer to Disassembly and Assembly, "Axle - Remove and Install". Note: Cleanliness is an important factor. Before the disassembly procedure, the exterior of the component should be thoroughly cleaned. This will help to prevent dirt from entering the internal mechanism. NOTICE https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 2/5 Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. Personal injury can result from hydraulic oil pressure and hot oil. Hydraulic oil pressure can remain in the hydraulic system after the engine has been stopped. Serious injury can be caused if this pressure is not released before any service is done on the hydraulic system. Make sure all of the work tools have been lowered to the ground, and the oil is cool before removing any components or lines. Remove the oil filler cap only when the engine is stopped, and the filler cap is cool enough to touch with your bare hand. Illustration 1 g00992346 1. Remove bolts (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 3/5 Illustration 2 g00992348 2. Install Tooling (A) and remove housing (2). Illustration 3 g00992349 3. Remove two bolts (3) and bolt (4) in order to install Tooling (C). Remove two bolts (5). Illustration 4 g00865077 4. Remove bolts (6) from the top of the sprocket segment. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 4/5 Illustration 5 g00994019 5. Install Tooling (B). Adjust the hook of Tooling (B) to the maximum length. Illustration 6 g00992350 6. Remove remaining bolts (3) and the washers. Illustration 7 g00992351 7. Attach Tooling (D) to Tooling (C) and Tooling (B). 8. Separate the final drive approximately 152 mm (6.0 inch). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 5/5 9. Release the pressure on Tooling (D). Rotate the brake housing 90 degrees in the counterclockwise direction. Illustration 8 g00992352 10. Rotating the brake housing allows pinion (7) to point forward. Rotating the brake housing will allow the final drive to swing toward the front of the machine. Rotating the brake housing will allow clearance for the ring gear to clear the machine. The weight of the final drive assembly is approximately 680 kg (1500 lb). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

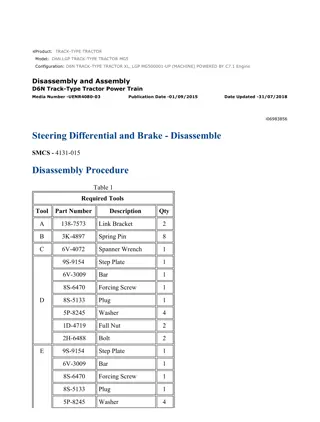

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 1/22 Product: TRACK-TYPE TRACTOR Model: D6N TRACK-TYPE TRACTOR CCS Configuration: D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE) POWERED BY 3126B ENGINE Disassembly and Assembly D6N Track-Type Tractor Power Train Media Number -RENR5257-04 Publication Date -01/12/2015 Date Updated -15/12/2015 i06983810 Steering Differential and Brake - Disassemble SMCS - 4131-015 Disassembly Procedure Table 1 Required Tools Tool Part Number Description Qty A 138-7573 Link Bracket 2 B 3K-4897 Spring Pin 8 C 6V-4072 Spanner Wrench 1 9S-9154 Step Plate 1 6V-3009 Bar 1 8S-6470 Forcing Screw 1 D 8S-5133 Plug 1 5P-8245 Washer 4 1D-4719 Full Nut 2 2H-6488 Bolt 2 E 9S-9154 Step Plate 1 6V-3009 Bar 1 8S-6470 Forcing Screw 1 8S-5133 Plug 1 5P-8245 Washer 4 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 2/22 1D-4719 Full Nut 2 1D-4574 Bolt 2 8H-0663 Bearing Puller 1 F 138-7575 Link Bracket 3 8B-7550 Leg 2 8B-7559 Adapter 2 3H-0465 Plate 4 1P-0498 Plate 1 1B-4207 Full Nut 2 G 5H-9976 Screw 1 5B-0637 High Idle Nut 1 8H-0684 Ratchet Wrench 1 8B-7563 Handle 1 5F-7353 Washer 1 8B-7548 Push-Puller Tool Gp 1 Start By: a. Remove the left final drive, the steering differential, and the brake. Refer to Disassembly and Assembly, "Final Drive, Steering Differential, and Brake (Left Side) - Remove" . https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 3/22 Illustration 1 g00993890 1. Remove bolts (1) and the washers. 2. Remove two opposite bolts (2). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 4/22 Illustration 2 g00823691 3. Install Tooling (A) and a suitable lifting device. 4. Remove sliding carrier (3). The weight of sliding carrier (3) is approximately 48 kg (105 lb). 5. Remove Tooling (A). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 5/22 Illustration 3 g06187075 6. Remove remaining bolts (2) and slinger (4) from planetary carrier (7). 7. Remove retaining ring (5), thrust ring (5A), and planetary carrier (7) from ring gear (6). Illustration 4 g00823775 8. Remove O-ring seal (10) from planetary carrier (7). 9. Use a hammer and a punch to push pin (12) in shaft (11). 10. Remove shaft (11), planetary gear (9), discs (8), and bearing (13) from planetary carrier (7). 11. Remove pin (12) from shaft (11). 12. Repeat Steps 9 through 11 for the remaining planetary gears. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 6/22 Illustration 5 g00823759 13. Remove lockring (14) and remove retaining ring (16). 14. Remove sun gear (15) from planetary carrier (18). 15. Remove spacer (17). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

D6N TRACK-TYPE TRACTOR PS DS XL/PS DS LGP CCS00001-UP (MACHINE)... 7/22 Illustration 6 g00995126 16. Remove bolts (19), plate (20), and gear (21) from planetary carrier (18). 17. Use Tooling (B) to compress the retaining ring that holds planetary carrier (18) in ring gear (6). 18. Separate planetary carrier (18) from ring gear (6). 19. Remove the retaining ring from planetary carrier (18). 20. Use a hammer and a punch to push pin (23) in shaft (24). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/10/27

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com