Caterpillar Cat 903D COMPACT WHEEL LOADER (Prefix MZY) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn// n

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Service Repair Manual Models 903DCOM PACT WHEEL LOADER

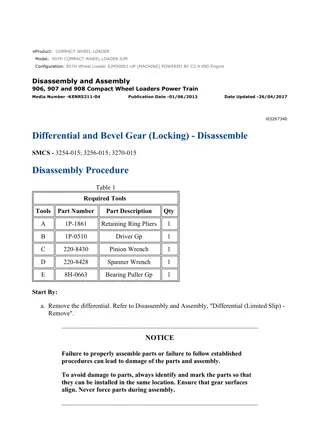

w 1/4(W) Shutdown SIS Previous Screen Product: COMPACT WHEEL LOADER Model: 903D COMPACT WHEEL LOADER MZY Configuration: 903D Compact Wheel Loader MZY00001-UP (MACHINE) POWERED BY C2.4 Engine Disassembly and Assembly 903D Compact Wheel Loader Machine Systems Media Number -M0094117-00 Publication Date -01/10/2018 Date Updated -22/10/2018 i07466073 Steering Frame Lock - Remove and Install SMCS - 7506-010 Installation Procedure Personal injury or death can result from machine articulation or movement. Machine frames can move and a person can be crushed. Connect the steering frame lock link between the front and rear frames before working on machine. Secure clevis pin with locking pin. Before operating the machine, fasten the steering frame lock link into the stored position and secure the clevis pin with locking pin. Failure to lock into the stored position before operating can result in loss of steering. 1. Move the machine to a hard, level surface. Position the machine in a manner in which the bores are aligned. Park the machine in the straight ahead position and engage the parking brake. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 2/4(W) Illustration 1 g06335223 Illustration 2 g06335225 2. Remove pin (2). Remove steering frame lock (1) from the stored position. Illustration 3 g06335236 3. Install steering frame lock (1). Install pin (2). Removal Procedure https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

w 3/4(W) Personal injury or death can result from machine articulation or movement. Machine frames can move and a person can be crushed. Connect the steering frame lock link between the front and rear frames before working on machine. Secure clevis pin with locking pin. Before operating the machine, fasten the steering frame lock link into the stored position and secure the clevis pin with locking pin. Failure to lock into the stored position before operating can result in loss of steering. Illustration 4 g06335236 1. Position the machine in a manner in which steering frame lock (1) can rotate in the bore. Remove pin (2) and steering frame lock (1). Illustration 5 g06335223 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 4/4(W) Illustration 6 g06335225 2. Install steering frame lock (1) to the stored position. Install pin (2). Copyright 1993 - 2019 Caterpillar Inc. Sun Sep 1 11:28:51 UTC+0800 2019 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 1/6(W) Shutdown SIS Previous Screen Product: COMPACT WHEEL LOADER Model: 903D COMPACT WHEEL LOADER MZY Configuration: 903D Compact Wheel Loader MZY00001-UP (MACHINE) POWERED BY C2.4 Engine Disassembly and Assembly 903D Compact Wheel Loader Machine Systems Media Number -M0094117-00 Publication Date -01/10/2018 Date Updated -22/10/2018 i07420631 Hydraulic Tank - Remove and Install SMCS - 4332-010; 5056-010; 5056-011; 5056-012 Removal Procedure Table 1 Required Tools Tool Part Number Description Qty A 422-5472 Lifting Eye Assembly 1 Start By: a. Release the hydraulic system pressure. b. Remove the cab. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, PERJ1017, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 2/6(W) Personal injury can result from hydraulic oil pressure and hot oil. Hydraulic oil pressure can remain in the hydraulic system after the engine has been stopped. Serious injury can be caused if this pressure is not released before any service is done on the hydraulic system. Make sure all of the attachments have been lowered, oil is cool before removing any components or lines. Remove the oil filler cap only when the engine is stopped, and the filler cap is cool enough to touch with your bare hand. 1. Drain the hydraulic tank into a suitable container. Refer to Operation and Maintenance Manual, "Hydraulic Oil - Change" for the correct draining procedures. Illustration 1 g06326247 2. Remove bolts (1). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 3/6(W) Illustration 2 g06326282 3. Disconnect harness assembly (2). Disconnect harness assembly (3). Illustration 3 g06326300 4. Disconnect hose assembly (4). Disconnect hose assemblies (5) and (6). Disconnect fitting (7). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 4/6(W) Illustration 4 g03467569 5. Remove hose (8). Illustration 5 g03467604 6. Remove fitting (12). Remove fitting (9). Remove fittings (10) and (11). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 5/6(W) Illustration 6 g03467617 7. Attach Tooling (A) and a suitable lifting device. Remove bolts (13) and (14). Remove hydraulic tank (15). The weight of hydraulic tank (15) is approximately 28 kg (62 lb.) Illustration 7 g03467622 8. Remove vent (16). Remove bolts (17). Remove plate (18). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 6/6(W) Illustration 8 g03468001 9. Remove strainer (19). Installation Procedure 1. Install hydraulic tank (15) in the reverse order of removal. Copyright 1993 - 2019 Caterpillar Inc. Sun Sep 1 11:29:39 UTC+0800 2019 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 1/2(W) Shutdown SIS Previous Screen Product: COMPACT WHEEL LOADER Model: 903D COMPACT WHEEL LOADER MZY Configuration: 903D Compact Wheel Loader MZY00001-UP (MACHINE) POWERED BY C2.4 Engine Disassembly and Assembly 903D Compact Wheel Loader Machine Systems Media Number -M0094117-00 Publication Date -01/10/2018 Date Updated -22/10/2018 i07521628 Joystick Control and Mounting - Remove and Install SMCS - 5059-010-MT; 5705-010-MT Removal Procedure Start By: a. Release the hydraulic system pressure. Illustration 1 g06343468 1. Open the right side cab door. Remove cover (4). Remove cover (3). Remove knob (1). Remove cover (2). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 2/2(W) Illustration 2 g06343630 2. Remove bolts (5). Disconnect cable assembly (6) and cable assembly (7) from the hydraulic hand control group. Illustration 3 g06347649 3. Disconnect harness assemblies (10). Remove screws (9) and joystick control and mounting (8). Installation Procedure 1. Install joystick control and mounting (8) in the reverse order of removal. Copyright 1993 - 2019 Caterpillar Inc. Sun Sep 1 11:30:27 UTC+0800 2019 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 1/6(W) Shutdown SIS Previous Screen Product: COMPACT WHEEL LOADER Model: 903D COMPACT WHEEL LOADER MZY Configuration: 903D Compact Wheel Loader MZY00001-UP (MACHINE) POWERED BY C2.4 Engine Disassembly and Assembly 903D Compact Wheel Loader Machine Systems Media Number -M0094117-00 Publication Date -01/10/2018 Date Updated -22/10/2018 i07424176 Metering Pump (Steering) - Remove and Install SMCS - 4312-010; 4312-011 Removal Procedure NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, PERJ1017, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. Personal injury can result from hydraulic oil pressure and hot oil. Hydraulic oil pressure can remain in the hydraulic system after the engine has been stopped. Serious injury can be caused if this pressure is not released before any service is done on the hydraulic system. Make sure all of the attachments have been lowered, oil is cool before removing any components or lines. Remove the oil filler cap only when https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 2/6(W) the engine is stopped, and the filler cap is cool enough to touch with your bare hand. Note: Mark all hoses and all hose assemblies for installation purposes. 1. Release the system pressure. Refer to Operation and Maintenance Manual, "System Pressure Release". Illustration 1 g03471582 2. Remove cover (1). Illustration 2 g03471599 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 3/6(W) 3. Disconnect hose assembly (2). Disconnect hose assembly (3). Illustration 3 g03471654 4. Disconnect hose assembly (4). Illustration 4 g03471645 5. Disconnect hose assemblies (5). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 4/6(W) Illustration 5 g03472756 6. Remove bolt (6). Illustration 6 g03472829 7. Remove bolt (7). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 5/6(W) Illustration 7 g03472977 Illustration 8 g06319340 Some components may be removed for the purpose of clarity. 8. Remove bolt (8). 9. Remove metering pump (9). Installation Procedure https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 6/6(W) Incorrect installation of the pilot supply lines for the Hand Metering Unit (HMU) with the presence of pressure in the steering supply circuit will cause the steering system to turn unexpectedly or turn in the wrong direction. These conditions can also cause the steering wheel to turn independently with or without an operator present in the cab. These situations could result in personal injury or death. Ensure that the pilot supply lines for the HMU have been installed correctly in the proper locations on the HMU before operating the machine. 1. Install metering pump (9) in the reverse order of removal. a. Start the machine. Turn the steering wheel in both directions. Purge all air from the hydraulic system. b. Check the hydraulic fluid level. Refer to Operations and Maintenance Manual, "Hydraulic Oil - Change". Copyright 1993 - 2019 Caterpillar Inc. Sun Sep 1 11:31:15 UTC+0800 2019 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 1/4(W) Shutdown SIS Previous Screen Product: COMPACT WHEEL LOADER Model: 903D COMPACT WHEEL LOADER MZY Configuration: 903D Compact Wheel Loader MZY00001-UP (MACHINE) POWERED BY C2.4 Engine Disassembly and Assembly 903D Compact Wheel Loader Machine Systems Media Number -M0094117-00 Publication Date -01/10/2018 Date Updated -22/10/2018 i07424475 Steering Cylinder - Remove and Install SMCS - 4303-010 Removal Procedure Start By: a. Install the steering lock. b. Remove the front cover. NOTICE Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids. Refer to Special Publication, PERJ1017, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products. Dispose of all fluids according to local regulations and mandates. Personal injury can result from hydraulic oil pressure and hot oil. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 2/4(W) Hydraulic oil pressure can remain in the hydraulic system after the engine has been stopped. Serious injury can be caused if this pressure is not released before any service is done on the hydraulic system. Make sure all of the attachments have been lowered, oil is cool before removing any components or lines. Remove the oil filler cap only when the engine is stopped, and the filler cap is cool enough to touch with your bare hand. 1. Release the hydraulic system pressure. Refer to Operation and Maintenance Manual, "System Pressure Release". Illustration 1 g03469137 2. Disconnect hose assemblies (3). Remove clamp (2). Remove pin (1). Remove the shims. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

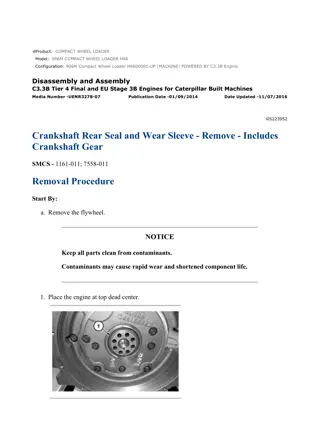

w 3/4(W) Illustration 2 g03469196 3. Remove clamp (4). Remove pin (5). Remove steering cylinder (6). Remove the shims. Installation Procedure 1. Install steering cylinder (6) in the reverse order of removal. Disassembly Information Table 1 Required Tooling Item Part Number Part Description Qty A 152-4251 Hydraulic Cylinder Repair Stand 1 B - Loctite 262 1 Illustration 3 g06319042 1. (1) Head. The torque for head (1) is 441 44 N m (325 33 lb ft). 2. (2) O-ring seal. 3. (3) Bushing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 4/4(W) 4. (4) U-Cup seal. 5. (5) Backup ring. 6. (6) O-ring seal. 7. (7) Piston. 8. (8) Piston ring. 9. (9) Wear ring. 10. (10) Piston nut. Apply Tooling (B) to the threads of piston nut (B). The torque for piston nut (10) is 324 33 N m (239 24 lb ft). 11. (11) Dust seal. 12. (12) Retaining ring. 13. (13) Bushing. 14. (14) Tube assembly. The torque for tube assembly (14) is 66 12 N m (550 9 lb ft). Copyright 1993 - 2019 Caterpillar Inc. Sun Sep 1 11:32:03 UTC+0800 2019 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 1/3(W) Shutdown SIS Previous Screen Product: COMPACT WHEEL LOADER Model: 903D COMPACT WHEEL LOADER MZY Configuration: 903D Compact Wheel Loader MZY00001-UP (MACHINE) POWERED BY C2.4 Engine Disassembly and Assembly 903D Compact Wheel Loader Machine Systems Media Number -M0094117-00 Publication Date -01/10/2018 Date Updated -22/10/2018 i07427535 Brake Accumulator - Remove and Install SMCS - 4263-010 Personal injury or death can result from sudden machine movement. Sudden movement of the machine can cause injury to persons on or near the machine. To prevent injury or death, make sure that the area around the machine is clear of personnel and obstructions before operating the machine. Personal injury can result from hydraulic oil pressure and hot oil. Hydraulic oil pressure can remain in the hydraulic system after the engine has been stopped. Serious injury can be caused if this pressure is not released before any service is done on the hydraulic system. Make sure all of the attachments have been lowered, oil is cool before removing any components or lines. Remove the oil filler cap only when the engine is stopped, and the filler cap is cool enough to touch with your bare hand. Removal Procedure https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

w 2/3(W) Start By: a. Connect the steering frame lock. 1. Release the brake pressure: Cycle the brake pedal up and down until all brake pressure is released. Refer to Operation and Maintenance Manual, "System Pressure Release". Illustration 1 g06320440 2. Remove floor mat (1). Illustration 2 g06320449 3. Remove screws (3) and cover (2). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

w 3/3(W) Illustration 3 g06320685 Some components may be removed or altered for the sake of clarity. Illustration 4 g06320700 Some components may be removed or altered for the sake of clarity. 4. Remove brake accumulator (4). Installation Procedure 1. Install brake accumulator (4) in the reverse order of removal. a. Tighten brake accumulator (4) to a torque of 60 6 N m (44 4 lb ft). Copyright 1993 - 2019 Caterpillar Inc. Sun Sep 1 11:32:51 UTC+0800 2019 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2019/9/1

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com