Caterpillar Cat 350 and 350L EXCAVATOR (Prefix 9DK) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

w 1/22(W) Product: EXCAVATOR Model: 350 L EXCAVATOR 9DK Configuration: 350 350L TRACK-TYPE EXCAVATORS 9DK00001-00300 (MACHINE) POWERED BY 3306 ENGINE Disassembly and Assembly 350 AND 350 L EXCAVATOR MACHINE SYSTEMS Media Number -SENR6148-04 Publication Date -01/11/2004 Date Updated -12/03/2010 SENR61480046 Swing Pump & Pump Drive SMCS - 3108-010; 5473-017; 5473 Remove & Install Swing Pump & Pump Drive At operating temperature, the hydraulic oil tank is hot and under pressure. Hot oil can cause burns. To prevent possible personal injury, release the pressure in the implement hydraulic circuits (boom, stick and bucket) before any hydraulic lines or components are disconnected or removed. 1. Release the pressure in the hydraulic system as follows: a. Fully retract the rod in the stick cylinder. b. Adjust the position of the bucket so it will be flat on the ground when the boom is lowered. c. Lower the boom until the bucket is flat on the ground. d. Shut off the engine, and put the hydraulic activation control lever in the "Lock" position. e. Move the control levers for the boom, bucket, stick and swing through their full travel strokes. This will relieve any pressure that may be present in the pilot system. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 2/22(W) f. Slowly loosen the air breather cap on the hydraulic oil tank to release the pressure. g. Tighten the air breather cap on the hydraulic oil tank. h. The pressure in the hydraulic system has now been released. Lines and components can now be removed. 2. Drain the oil from the hydraulic oil tank into a suitable container for storage or disposal. The capacity of the hydraulic oil tank is 240 liters (63.3 U.S. gal). 3. Open the hood assembly of the machine, and lock it in position. 4. Open two right rear access doors (2). Remove cover assembly (1). 5. Put identification marks on all hose assemblies that are connected to the pilot pump and the swing pump. 6. Disconnect hose assemblies (3), (4) and (5) from the pilot pump and the swing pump. Put plugs in the hose assemblies to prevent oil loss and to keep dirt and debris out of the hydraulic system. 7. Disconnect hose assemblies (8) from the pilot pump. Put plugs in the hose assemblies to prevent oil loss and to keep dirt and debris out of the hydraulic system. 8. Fasten a lifting sling and a hoist to swing pump (6) as shown. Remove four bolts (7) that hold the swing pump to the rear of the engine. Carefully remove the swing pump from the pump drive. The combined weight of the pilot pump and swing pump is 136 kg (300 lb). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 3/22(W) 9. Remove the O-ring seal from the pump housing. 10. Remove eight bolts (9) and plate (10) from the flywheel housing. 11. Remove bushing (11) from the plate. 12. Remove gear (12) from the flywheel housing. 13. Remove bushing (13) from the flywheel housing. NOTE: The following steps are for the installation of the swing pump and pump drive. NOTICE https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

w 4/22(W) The swing pump must be filled with hydraulic oil before operation or damage to the unit will result. Add hydraulic oil through the drain port of the swing pump. 14. Check the condition of the O-ring seal used between the swing pump and the pump drive. Also check the condition of the O-ring seals used in the ends of the hose assemblies that connect to the swing and pilot pumps. If any of the seals are damaged, use new parts for replacement. 15. Lower the temperature of bushing (13), and install it in the flywheel housing with Tool (A). Install the bushing until it is even with the inside surface of the flywheel housing. Lubricate the bushing with clean hydraulic oil. 16. Put gear (12) in position in the flywheel housing. 17. Lower the temperature of bushing (11), and install it in plate (10) with Tool (A). Install the bushing until it makes contact with the counterbore in the plate. Lubricate the bushing with clean hydraulic oil. 18. Put plate (10) in its original position on the flywheel housing. Install eight bolts (9) that hold it. 19. Install the O-ring seal on the swing pump housing. Lubricate the O-ring seal with clean hydraulic oil. 20. Fasten a lifting sling and a hoist to swing pump (6). Put the swing pump in position in the flywheel housing. Install four bolts (7) that hold it. 21. Connect hose assemblies (8) to the pilot pump. 22. Connect hose assemblies (3), (4) and (5) to the swing and pilot pumps. 23. Fill the hydraulic oil tank with oil to the correct level. Refer to the 350 & 350 L Excavators Operation & Maintenance Manual for the correct filling procedure. 24. Start the machine, and check the operation of the swing function and the implements. Also, check for oil leaks. 25. Reinstall cover assembly (1). Close access doors (2) and the hood assembly. Disassemble & Assemble Swing Pump Start By: https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 5/22(W) a. remove swing pump 1. Make sure the swing pump is thoroughly clean prior to disassembly. 2. Fasten the swing pump to Tool (A) as shown. The combined weight of the swing pump and pilot pump is 136 kg (300 lb). 3. Remove the pilot pump from the swing pump. Refer to the topic "Remove & Install Pilot Pump" in this module. 4. Remove four socket head bolts (1) and cover (2) from the head group. 5. Remove O-ring seal (3) from the cover. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 6/22(W) 6. Remove five socket head bolts (4) and pressure and flow compensator valve group (5) from the head group. 7. Disassemble pressure and flow compensator valve group (5) as follows: a. Remove four O-ring seals (6), two pins (7) and actuator group (8). b. Disassemble the actuator group. Remove valve (9), roller assembly (10) and spring (11). c. Remove two clips (12). Disconnect roller (13) from valve (14). d. Remove clip (15). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 7/22(W) e. Remove pin (16) and track assembly (17). f. Remove flow compensator valve group (18). g. Disassemble the flow compensator valve group. Remove spool (19). Remove connector (29) from plug (24). h. Remove retainer (20), spring (21) and retainer (22) from plug (24). Remove O-ring seal (23) from plug (24). i. Remove retaining ring (27), shims (26) and piston (25) from plug (24). Remove O-ring seal (28) from connector (29). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 8/22(W) j. Remove flow compensator valve group (30) from the valve group housing. k. Disassemble flow compensator valve group (30). Remove spool (31), retainer (32), spring (33), retainer (34) and O-ring seal (35) from plug (36). l. Remove four bolts (37) and connector (38) from the valve group housing. m. Remove spring (39) and O-ring seal (40) from connector (38). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 9/22(W) n. Remove valve assembly (41) from the housing. o. Disassemble valve assembly (41). Remove piston (44), valve (41), valve (43) and seat (42). 8. Remove coupler (45) from the head group. 9. Remove four socket head bolts (46) that hold the head group to the pump housing. 10. Fasten Tool (B) and a hoist to head group (47) as shown. Remove the head group from the pump housing. The weight of the head group is 41 kg (90 lb). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 10/22(W) 11. Remove O-ring seal (48) from the head group. 12. If necessary, remove pin (49) from the head. 13. Remove bearing (50) from the head. 14. Remove actuator groups (51) and (52) from the pump housing. 15. Disassemble actuator groups (51) and (52) as follows: a. Remove rod (53) and spring (54) from actuator (51). b. Remove rod (55) and spring (56) from actuator (52). 16. Remove thrust plate (57) from the rotating group. Remove two dowels (58) from the pump housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 11/22(W) 17. Remove four socket head bolts (60) and two segments (61). Remove barrel assembly (59) from the pump housing. 18. Disassemble barrel assembly (59) as follows: a. Remove nine piston assemblies (62) and plate (63) as a unit from barrel (66). Separate the piston assemblies from the plate. b. Remove ball (64), spring set (65) and the shims from barrel (66). 19. Remove two setscrews (67) from the pump housing. 20. Remove swash plate (68) from the pump housing. 21. Remove bearing sets (69) and the two rods with the bearing sets from the pump housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 12/22(W) 22. Remove four socket head bolts (70) from the cover. 23. Using a soft faced hammer, remove the shaft assembly from the pump housing in the direction shown. 24. Remove two O-ring seals (71) from cover (72). Remove cover (72) fromshaft (73). Remove the two lip-type seals from the cover. 25. Remove retaining ring (74) and bearing (75) from shaft (73). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 13/22(W) 26. Using a soft faced hammer, remove flange (76) from the pump housing. 27. Remove O-ring seal (77) from flange (76). NOTE: The following steps are for the assembly of the swing pump. For details on all specifications for the swing pump, refer to the topic "Swing Pump" in the 350 And 350 L Excavators Hydraulic System Specification module. 28. Make sure all parts of the swing pump are thoroughly clean prior to assembly. Check the condition of all O-ring seals used in the pump. If any of the seals are damaged, use new parts for replacement. 29. Put clean hydraulic oil on all parts of the swing pump during assembly. 30. Install bearing (75) and retaining ring (74) on shaft (73). 31. Install O-ring seal (77) on flange (76). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 14/22(W) 32. Install flange (76) on shaft (73). 33. Install bearing sets (69) and rods (78) on flange (76). 34. Install swash plate (68) in the flange. Make sure rods (78) are installed as shown. 35. Assemble barrel assembly (59) as follows: a. Install the original amount of shims, spring set (65) and ball (64) on barrel (66). b. Put nine piston assemblies (62) in plate (63). Install the piston assemblies with the plate in the barrel. Make sure the plate moves smoothly over the surface of ball (64). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 15/22(W) NOTICE Do not let barrel assembly (59) come apart during installation on shaft (73). If any of the components of the barrel assembly come out of place, damage to the swing pump can result. 36. Install barrel assembly (59) on shaft assembly (73). Make sure all components of barrel assembly (59) are in place. 37. Put 9S-3263 Thread Lock on the threads of four socket head bolts (60). Install two segments (61) and four socket head bolts (60). Tighten the socket head bolts to a torque of 8 2 N m (6 1 lb ft). 38. Fasten a lifting sling and a hoist to the rotating group as shown. Install the rotating group in the pump housing. Make sure flange (76) engages properly with the dowels in the bottom of the pump housing. Reinstall setscrews (67) in the pump housing. For adjustment of setscrews (67), refer to the 350 And 350 L Excavators Hydraulic System Testing & Adjusting module. 39. Using Tool (C), install the two lip-type seals in cover (72). Install each seal until it makes contact with the counterbore in the cover and with the sealing lip of each seal facing each other. Install two O-ring seals (71) on cover (72). Lubricate the sealing lip of each seal with clean hydraulic oil. 40. Put cover (72) in position in the pump housing. Install four socket head bolts (70) that hold it. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 16/22(W) 41. Install two dowels (58) in the pump housing. Install thrust plate (57) on the rotating group. 42. Assemble actuator groups (51) and (52) as follows: a. Install spring (56) and rod (55) in actuator (52). b. Install spring (54) and rod (53) in actuator (51). 43. Install actuator groups (51) and (52) in their original locations in the pump housing. 44. Install bearing (50) in the head. Make sure the bearing is seated in the counterbore in the head. 45. Reinstall pin (49) in the head. 46. Install O-ring seal (48) in the head. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 17/22(W) 47. Fasten Tool (B) and a hoist to head group (47). Put the head group in its original position on the pump housing. 48. Install four socket head bolts (46) that hold the head group to the pump housing. Tighten the bolts to a torque of 530 53 N m (390 39 lb ft). 49. Install coupler (45) on the shaft. 50. Assemble pressure and flow compensator valve group (5) as follows: a. Assemble valve assembly (41). Install seat (42), valve (43), valve (41) and piston (44). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 18/22(W) b. Install valve assembly (41) in the housing as shown. c. Install spring (39) and O-ring seal (40) on connector (38). d. Put connector (38) in position on the valve group housing. Install four bolts (37) that hold it. e. Assemble flow compensator valve group (30). Install O-ring seal (35) on plug (36). Install retainer (34), spring (33), retainer (32) and spool (31). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 19/22(W) f. Install flow compensator valve group (30) on the valve group housing. g. Assemble the flow compensator valve group. Install O-ring seal (28) on connector (29). Install piston (25), shims (26) and retaining ring (27). h. Install O-ring seal (23) on plug (24). Install retainer (22), spring (21) and retainer (20) in plug (24). i. Install connector (29) in plug (24). Install spool (19). j. Install flow compensator valve group (18) in the housing. k. Install track assembly (17) and pin (16) in the housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 20/22(W) l. Install clip (15) in the housing. m. Assemble the actuator group. Connect roller (13) to valve (14). Install two clips (12). n. Install spring (11), roller assembly (10), and valve (9). o. Install actuator group (8) in the valve housing as shown. Install two pins (7) and four O-ring seals (6) in the valve housing. 51. Put pressure and flow compensator valve group (5) in position on the head group. Install five socket head bolts (4) that hold it. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 21/22(W) 52. Install O-ring seal (3) on cover (2). 53. Put cover (2) in position on the head group, and install four socket head bolts (1) that hold it. 54. Reinstall the pilot pump on the swing pump. Refer to the topic "Remove & Install Pilot Pump" in this module. NOTICE The swing pump must be filled with clean hydraulic oil before operation or damage to the unit will result. Add clean hydraulic oil through the drain port of the swing pump. End By: a. install swing pump https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

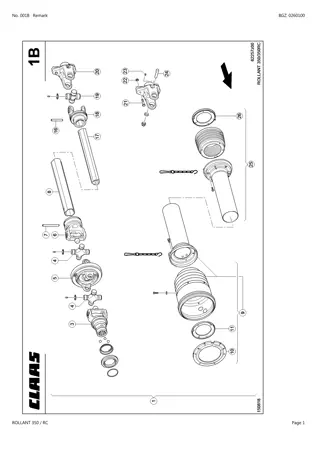

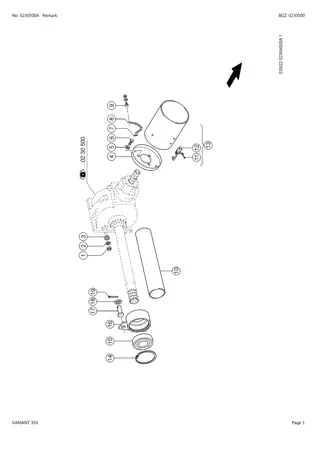

w 1/2(W) Product: EXCAVATOR Model: 350 L EXCAVATOR 9DK Configuration: 350 350L TRACK-TYPE EXCAVATORS 9DK00001-00300 (MACHINE) POWERED BY 3306 ENGINE Disassembly and Assembly 350 AND 350 L EXCAVATOR MACHINE SYSTEMS Media Number -SENR6148-04 Publication Date -01/11/2004 Date Updated -12/03/2010 SENR61480047 Auxiliary Drive SMCS - 3108-010 Remove & Install Auxiliary Drive 1. Open the two right rear access doors. 2. Remove eight bolts (1) and cover assembly (2) from the flywheel housing. 3. Remove bushing (3) from the cover. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 2/2(W) 4. Remove gear (4) from the flywheel housing. 5. Remove bushing (5) from the flywheel housing. NOTE: The following steps are for the installation of the auxiliary drive. 6. Lower the temperature of bushing (5), and install it in the flywheel housing with tool (A). Install the bushing until it is even with the inside surface of the flywheel housing. Lubricate the bushing with clean hydraulic oil. 7. Reinstall gear (4) in the flywheel housing. 8. Lower the temperature of bushing (3), and install it in the cover with tool (A). Install the bushing until it makes contact with the counterbore in the cover. Lubricate the bushing with clean hydraulic oil. 9. Put cover assembly (2) in its original position on the flywheel housing. Install eight bolts (1) that hold it. 10. Close the two right rear access doors. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

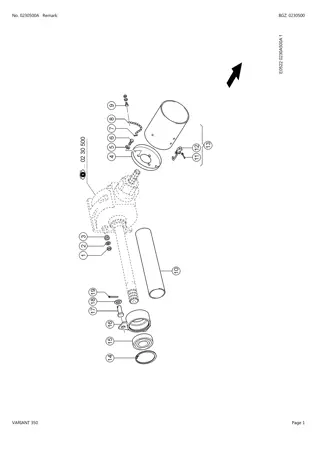

w 1/10(W) Product: EXCAVATOR Model: 350 L EXCAVATOR 9DK Configuration: 350 350L TRACK-TYPE EXCAVATORS 9DK00001-00300 (MACHINE) POWERED BY 3306 ENGINE Disassembly and Assembly 350 AND 350 L EXCAVATOR MACHINE SYSTEMS Media Number -SENR6148-04 Publication Date -01/11/2004 Date Updated -12/03/2010 SENR61480048 Main Hydraulic Pumps (Implement & Travel) & Pump Drive Coupling SMCS - 5062-010; 5070; 5084 Remove & Install Main Hydraulic Pumps (Implement & Travel) & Pump Drive Coupling At operating temperature, the hydraulic oil tank is hot and under pressure. Hot oil can cause burns. To prevent possible personal injury, release the pressure in the implement hydraulic circuits (boom, stick and bucket) before any hydraulic lines or components are disconnected or removed. 1. Release the pressure in the hydraulic system as follows: a. Fully retract the rod in the stick cylinder. b. Adjust the position of the bucket so it will be flat on the ground when the boom is lowered. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 2/10(W) c. Lower the boom until the bucket is flat on the ground. d. Shut off the engine, and put the hydraulic activation control lever in the "Lock" position. e. Move the control levers for the boom, bucket, stick and swing through their full travel strokes. This will relieve any pressure that may be present in the pilot system. f. Slowly loosen the air breather cap on the hydraulic oil tank to release the pressure. g. Tighten the air breather cap on the hydraulic oil tank. h. The pressure in the hydraulic system has now been released. Lines and components can now be removed. 2. Drain the oil from the hydraulic oil tank into a suitable container for storage or disposal. The capacity of the hydraulic oil tank is 240 liters (63.3 U.S. gal). 3. Open the hood assembly of the machine, and lock it in position. 4. Open two right rear access doors (2). Remove cover assembly (1). 5. Remove brace assembly (3) from the machine. 6. Remove two sheet assemblies (4). 7. Put identification marks on all hose assemblies (5) that are connect to the main hydraulic pumps. Disconnect all hose assemblies (5). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 3/10(W) 8. Disconnect tube assembly (6). 9. Fasten lifting slings and a hoist to main hydraulic pumps (7) as shown. Remove 12 bolts (8) that hold the main hydraulic pumps to the engine flywheel housing. NOTICE 26 rubber blocks are used on the spider assembly of the pump drive coupling. These rubber blocks can fall off of the spider assembly during removal of the main hydraulic pumps from the engine flywheel housing. Make sure not to loose any of the rubber blocks. NOTICE The main hydraulic pumps must be kept level during removal from the engine flywheel housing. If they are not held level, binding between the components will occur. This can result in parts damage. 10. While keeping main hydraulic pumps (7) level, slowly remove them from the engine flywheel housing. The combined weight of the main hydraulic pumps (implement and travel) and the pump drive coupling is 304 kg (670 lb). 11. Mark the position of drive ring gear (10) in relation to the engine flywheel. Remove eight bolts (9), the washers and ring gear (10) from the engine flywheel. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

w 4/10(W) 12. Remove 26 rubber blocks (11) from the spider assembly. These rubber blocks are a slip fit. 13. Remove four socket head bolts (13). 14. Remove bolt (14), the washer and plate (12) from the end of the pump drive shaft. NOTICE Four tapered wedge plates (16) hold the spider assembly to the pump drive shaft. The two tapered wedge blocks used on the back side of the spider assembly are a different size then the two used on the front side of the spider assembly. Do not mix the tapered wedge blocks during removal. 15. Install a suitable size bolt (15) with a flat washer in tapered wedge block (16) as shown. Using Tool (B), loosen the tapered wedge block, and remove it from the spider assembly. Loosen the other tapered wedge block the same way. NOTE: The tapered wedge blocks on the back side of the spider assembly can be loosened with a hammer and punch or when the spider assembly is slide off of the pump drive shaft. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

w 5/10(W) 16. Remove spider assembly (17) from the pump drive shaft. Remove the two tapered wedge blocks from the rear side of the spider assembly. 17. Remove eight bolts (18) that hold flange (19) and spider (20) together. Separate the flange from the spider. 18. Fasten Tool (A), a lifting sling and a hoist to cover (21) as shown. Remove four socket head bolts (23) and the washers that hold cover (21) and spacer (22) to the travel pump housing. Remove the cover and spacer. 19. Put identification marks on all hose assemblies (24) that are connected between the implement pump and the travel pump. Disconnect the hose assemblies. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/siswe... 2022/3/7

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com